Importance of Rig Safety Table Mats

Rig safety table mats are a crucial component in ensuring the safety and well-being of workers in the oil and gas industry. These mats not only provide a non-slip surface but also offer insulation against electric shocks, protecting employees from potential hazards. Additionally, rig safety table mats act as a protective barrier against spills and chemical exposure, reducing the risk of accidents and injuries in high-risk work environments.

By investing in high-quality rig safety table mats, companies demonstrate their commitment to prioritizing worker safety. These mats are designed to withstand heavy use and harsh conditions, providing long-term protection for both personnel and equipment. Moreover, utilizing durable rig safety table mats can contribute to cost savings by reducing maintenance expenses associated with damaged or worn-out surfaces. Ultimately, these mats play a fundamental role in creating a secure work environment where employees can perform their duties with confidence and peace of mind.

Material Considerations for Safety Mats

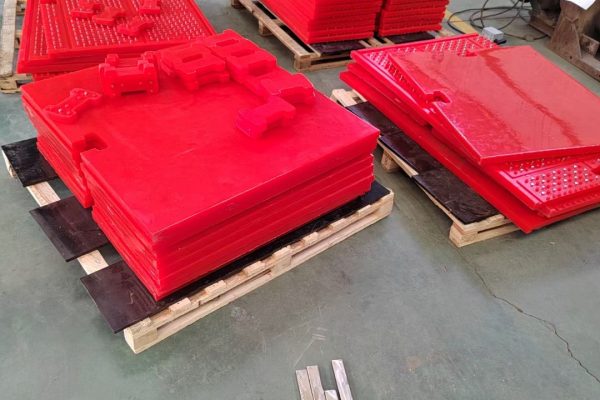

When it comes to safety mats for rig tables, material considerations play a crucial role in ensuring effectiveness and durability. One of the most important factors to consider is the resistance of the material to oil, grease, and other liquids commonly found in industrial settings. Mats made from durable rubber compounds are ideal as they offer excellent resistance to these substances, ensuring a safer and more reliable working surface.

In addition to resistance, the material should also provide sufficient traction to prevent slips and falls. This makes materials with textured surfaces or anti-slip properties highly desirable for safety mats. Furthermore, considering the potential exposure to extreme temperatures and heavy machinery, it’s essential that the chosen material can withstand these challenges without compromising its performance. By evaluating these material considerations thoroughly, one can select safety mats that not only enhance workplace safety but also offer long-term value and reliability.

Size and Thickness Guidelines

When considering size and thickness guidelines for rig safety table mats, it’s important to factor in the specific environment and potential hazards. The size of the mat should be large enough to cover the entire work surface, providing ample space for workers to move around and perform tasks without restriction. Additionally, the thickness of the mat plays a critical role in impact absorption and fatigue reduction. A thicker mat can provide better cushioning and support for standing workers, reducing the risk of strain or injury during long shifts.

https://suconvey.com/product-category/rig-floor-rotary-table-mats/

While standard guidelines exist for recommended sizes and thicknesses, it’s also crucial to assess individual needs based on the nature of the rig operation. Factors such as heavy machinery use, frequency of foot traffic, and potential spillage should all be taken into account when determining the most suitable specifications for rig safety table mats. By customizing these aspects according to specific work demands, companies can ensure optimal safety measures are in place to protect their workforce from preventable accidents.

Durability and Maintenance Requirements

When it comes to selecting the right rig safety table mat, durability and maintenance requirements are crucial factors to consider. A high-quality mat should be able to withstand the rigors of a busy working environment, including heavy foot traffic and potential spills or damage. Look for mats made from durable materials such as rubber or heavy-duty vinyl that can resist wear and tear over time.

In addition to durability, consider the maintenance requirements of the table mat. Some mats may require regular cleaning with specific products or methods, while others are designed to be low-maintenance and easy to clean. Finding a balance between durability and ease of maintenance is essential for ensuring that your investment in a rig safety table mat pays off in the long run. By carefully evaluating these factors, you can choose a table mat that will effectively protect against slips and falls while also being cost-effective in terms of upkeep.

Cost vs. Quality Analysis

When it comes to choosing the right rig safety table mat, it’s crucial to consider the balance between cost and quality. While cost is often a significant factor in decision-making, sacrificing quality for a lower price can lead to more significant expenses down the road. To avoid potential safety hazards and frequent replacements, investing in high-quality table mats may prove to be more cost-effective over time.

Moreover, higher-quality rig safety table mats are often designed to withstand harsh environments and heavy usage, ensuring long-term durability and reliability. As such, focusing solely on upfront costs without considering the long-term benefits of quality can be short-sighted. By conducting a thorough cost vs. quality analysis, companies can make informed decisions that prioritize both budget constraints and the overall safety and effectiveness of their equipment.

User Reviews and Recommendations

User Reviews and Recommendations offer a valuable source of insight into the effectiveness and quality of rig safety table mats. While product descriptions can provide a basic understanding, real user experiences can greatly influence purchasing decisions. By reading through user reviews, potential buyers can gauge the mat’s durability, slip resistance, and overall performance in various work environments. Furthermore, user recommendations can highlight specific features or benefits that may not be immediately apparent from manufacturer specifications. This crowd-sourced feedback provides a well-rounded view of the product’s strengths and weaknesses, helping customers make informed choices.

It’s important to note that while individual experiences may vary, patterns among user reviews can indicate consistent qualities of a rig safety table mat. Look for common praises or criticisms to gain a comprehensive understanding of its capabilities. Additionally, consider reaching out directly to users who have left detailed reviews for further insights or clarification on specific aspects of the mat’s functionality. User Reviews and Recommendations hold substantial weight in guiding prospective buyers toward selecting the most suitable rig safety table mat for their needs.

Conclusion: Making the Right Choice

In conclusion, making the right choice when selecting a rig safety table mat is crucial for ensuring the safety and well-being of workers in a high-risk environment. It’s important to carefully consider factors such as material durability, slip resistance, and ease of cleaning when choosing the appropriate mat for your specific work setting. Additionally, understanding the unique requirements and regulations of your industry will guide you towards making an informed decision that aligns with safety standards.

Ultimately, investing in a high-quality rig safety table mat can lead to long-term cost savings by reducing the likelihood of workplace accidents and injuries. By prioritizing employee safety through the selection of an appropriate mat, companies can also cultivate a culture of care and responsibility within their workforce. Keeping these considerations in mind will empower decision-makers to make choices that prioritize worker protection while simultaneously contributing to overall operational efficiency.