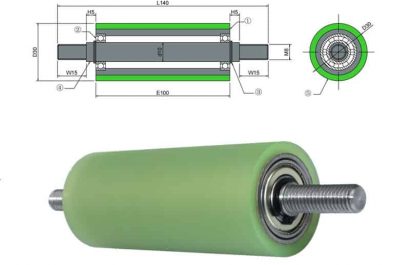

Custom Polyurethane Coated Rollers

We are the best customized cast polyurethane coated idler rollers manufacturer in China. Polyurethane coated rollers are rollers that have a polyurethane coating. This coating provides many benefits, including resistance to wear, abrasion, and chemicals. The core has aluminum, stainless steel, carbon steel. Polyurethane coated rollers are used in many industries, such as manufacturing, packaging, and printing. In addition to their resistance to wear and tear, polyurethane coated rollers also have excellent anti-static properties. This makes them ideal for use in environments where static electricity could be a problem, such as in semiconductor manufacturing.

Cast Polyurethane Coated Rollers mANUFACTURER

Key Features

- Resistant to oil, grease & chemicals

- Wide range of colors available

- High load bearing capacity

- Low rolling resistance

- Food grade, Industrial commercial grade available

- Wide functioning temperature range

- Extremely durable and resistant to tearing

Our service

- Cut to size

- On-time Dispatch Guarantee

- Supply free samples and design drawing

- Customize the size, thickness, color, hardness as you need

High QUality polyurethane rollers Factory

Polyurethane coated rollers have many advantages that make them the ideal choice for a wide variety of applications. They are extremely durable and resistant to abrasion, making them ideal for high-wear environments. They are also non-conductive, making them safe for use in electrical applications. Polyurethane coated rollers are chemical resistant and have excellent release properties, making them ideal for use in coating and laminating processes.

Types of Rollers:

> Conveyor Rollers

> Idler Rollers

> Applicator Rollers

> Coating Rollers

> Feeding Rollers

> Laminating Rollers

> Printing Rollers

> Snubber Rollers

> V-Rollers

> Guide Rollers

> Drive Rollers

> Straight Roller

> Custom Shaped Rollers

About Company

Professional custom Polyurethane products FACTORY

Suconvey is a professional silicone&PU rubber products manufacturer that chooses the highest quality raw materials from all over the world as our long time experience in this industry after comparing the materials from different countries and districts, we get rid of the materials with any bad feedback and products.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Mrs. Stephanie

- 86-13246961981

- [email protected]

Free Consultation

Urethane Parts for Conveyor System

We have developed a series of high quality, high performance Polyurethane rollers, Polyurethane wheels, Polyurethane rubber skirting, Polyurethane screen mats, Polyurethane Blades, Custom Urethane Products and so on. Polyurethane is a versatile material that can be used to manufacture products in a variety of ways. There are three main types of polyurethane parts: cast, extruded, and molded. Each type has its own unique benefits.

Wholesale Polyurethane Rubber Rollers

We are a leading Manufacturer of Polyurethane coated rollers from China. Polyurethane coated rollers are a type of roller that is commonly used in industrial and commercial applications. They are made from a variety of materials, including steel, stainless steel, aluminum, and even plastic. Some of the benefits of using a polyurethane coated roller include the fact that they last longer than other types of rollers, they resist corrosion well, and they provide a smooth surface for rolling. Additionally, these rollers are often quieter than other types of rollers when in use.

No matter how big or small the project is you can trust our expert craftsmen to deliver on time .

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently asked questions

Here are the most frequently asked questions and answers about how to buy customized polyurethane products

Polyurethane coated rollers are made by a process of bonding polyurethane to a metal core.

This process begins with the cleaning of the metal core. Any dirt or contaminants on the surface of the metal will cause the polyurethane to not bond properly.

Once the metal core is clean, a primer is applied to help the polyurethane adhere to the surface.

The next step is to apply the polyurethane coating itself. This is done using a machine that lays down a thin layer of polyurethane onto the surface of the metal core.

The thickness of the polyurethane coating can be controlled by adjusting the settings on the machine.

- Please confirm your inquiry request as the usefulness.

- Please measure your application place size and count the quantity. If you have drawing, better send to us. If you have no drawing please tell me your application and tell me where do you want to use it, better to know the application equipment model, we can make drawing or solutions for you.

- We will making drawing as your demands or required products photos or pictures.

- Please confirm the size and quantity, especially the specifications of what you want so that I can supply the most precise guide and suggestions.

- Making samples as your exact requirements and appplications.

- Testing and confirm the samples and making upgrade if necessary.

- Placing order and prepare the production.

- Arrange the delivery after out of warehouse test.

- After-sale service follow the goods always.

Before purchase: Give the most professional guide for choosing the right products or service system.

After purchase: Warranty for 1 or 2 years as the application and your requirements. Any damage will be repair or replace new during warranty as long as use the products as the right way and normal wear of the products apart from any break by personal reasons.

After-sale: Always give the most professional suggestions for the products working status, give support for customers marketing developments of own brand business. Always repair as long as we keep cooperation.

Yes, we can provide existing sample for free, but a little sample charge for custom design, new customers are expected to pay for the delivery cost, the sample charge will be deducted from the payment for formal order.

For existing product, it takes 1-2 days; If you want your design, it may take 3-5 days depends on your design content.

We have our QC department empowered with a professional QC team. “Quality First, Cutomer Focus” is our quality policy, and we have Incoming Quality Control / In-process Quality Control / Out-going Qualtiy Control throughout our factory operations.

To withstand all the above extreme working environment requirements, Suconvey has to choose the best quality raw materials which can not only produced good performance silicone products but also have many outstanding advantages such as will not change to yellow even use for a long time, will not become brittle easily broken, will not shrink or expand although using for a long time, will also not easily change the specification to influence your machine operation. Only based on the above quality control, silicone products can be serviced for a long time to save your energy to replace them and your time waiting for the replacement so that the productivity is high.