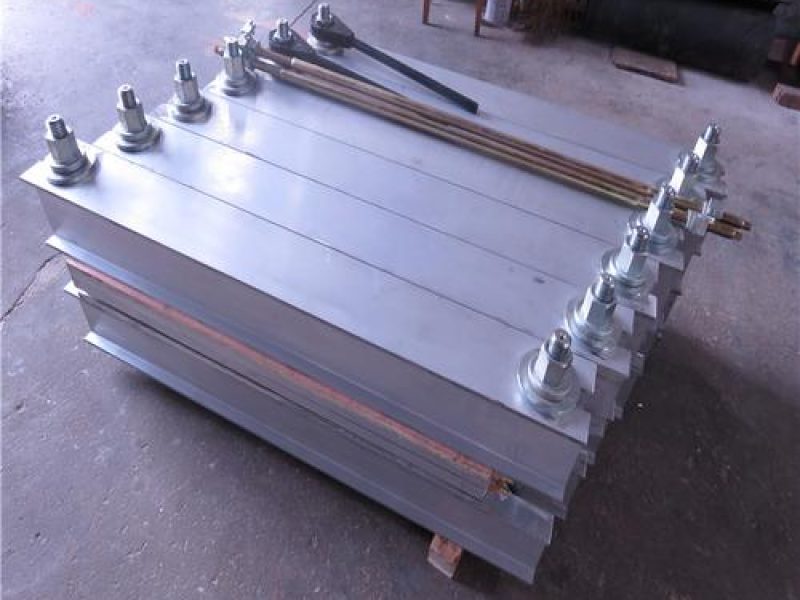

Rubber Conveyor Belt Hot Vulcanizing Press Machine

Suconvey Rubber company supplies high quality rubber conveyor belt hot splicing vulcanizing press machine. The hot splicing machine for fabric conveyor belt are mainly applied to industries for splicing and repairing for conveyor belts such as metallurgy, mine, power plant, port, dock, construction material cement, chemical industry , tobacco ,and food automatic line field.

Hot Splicing Conveyor Belt Vulcanizing Press Machine

Key Features

- Machine Maximum size: from 300MM-6000MM;

- Voltage: 220V 380V 415V 660V 50HZ;

- Fast Cooling time: 15 minutes (from 145 degrees down to 70 degrees or less);

- Time for temperature raise (from normal temperature to vulcanizing temperature) no more than 25 minutes;

- The temperature difference of sulfide surface: ±2°c.

- Temperature adjustment range: 0~300°c.

- Vulcanizing pressure: 0~2.5 MPa (details refer to users’ specifications and factory markings);

- Time of heat preservation for vulcanizing could be adjusted according to thickness of the rubber belts;

- Splicing length of rubber conveyor belt for vulcanizing jointing could be connected together by single or several pieces if necessary;

- Rubber conveyor belt as well as tension in kilogram required for vulcanizing jointing when ordering products.

- Users could order spare electric pumps additionally according to requirements.

Specifications of Suconvey Hot Vulcanizing Press Machine | ||||||

Order No. | Belt width(mm) | Item(mm) | Heating plate(mm) | Power(kw) | Size(mm) | Weight(kg) |

SUH/LH-650 | 650 | 650 x 830 | 830 x 820 | 9.8 | 1080 x 165 x 170 | 470 |

650 x 1000 | 1000 x 820 | 11.8 | 540 | |||

SUH/LH-800 | 800 | 800 x 830 | 830 x 995 | 11.97 | 1250 x 165 x 170 | 635 |

800 x 1000 | 1000 x 995 | 14.4 | 735 | |||

SUH/LH-1000 | 1000 | 1000 x 830 | 830 x 1228 | 14.7 | 1450 x 165 x 170 | 865 |

1000 x 1000 | 1000 x 1228 | 17.8 | 955 | |||

SUH/LH-1200 | 1200 | 1200 x 830 | 830 x 1431 | 17.2 | 1680 x 165 x 250 | 965 |

1200 x 1000 | 1000 x 1431 | 20.7 | 1150 | |||

SUH/LH-1400 | 1400 | 1400 x 830 | 830 x 1653 | 19.8 | 1900 x 165 x 250 | 1160 |

1400 x 1000 | 1000 x 1653 | 23.8 | 1460 | |||

SUH/LH-1600 | 1600 | 1600 x 830 | 830 x 1867 | 22.3 | 2140 x 165 x 270 | 1320 |

1600 x 1000 | 1000 x 1867 | 27 | 1570 | |||

SUH/LH-1800 | 1800 | 1800 x 830 | 830 x 2079 | 24.9 | 2350 x 165 x 320 | 1480 |

1800 x 1000 | 1000 x 2079 | 30 | 1850 | |||

SUH/LH-2000 | 2000 | 2000 x 830 | 830 x 2303 | 27.6 | 2550 x 165 x 360 | 1530 |

2000 x 1000 | 1000 x 2303 | 33.2 | 1900 | |||

SUH/LH-2200 | 2200 | 2200 x 830 | 830 x 2478 | 29.7 | 2750 x 165 x 360 | 1700 |

2200 x 1000 | 1000 x 2478 | 35.8 | 2000 | |||

SUH/LH-2400 | 2400 | 2400 x 830 | 830 x 2678 | 31.8 | 2940 x 165 x 360 | 1850 |

2400 x 1000 | 1000 x 2678 | 38.9 | 2200 | |||

Adjustable Hot Vulcanizing Machine Applications

- 8 years manufacturing experience

- High Quality

- After-sales support services

- Standard and Strict Dimension

Fabric Conveyor Belt

Adjustable Hot Splicing Belt Machine

Steel Cord Conveyor Belt

Light Hot Vulcanizing Belt Machine

Nylon Conveyor Belt

Portable Hot Joint Belt Machine

Don’t Know What To Start With?

Get A Solution For Your Project

About Company

contact us

Suconvey Wholesale Can Be Easy & Safe.

No matter what kind of hot vulcanizing belt machine you want, based on our extensive experience, we can manufacture and supply it for you.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Stephanie

- 86-13246961981

- [email protected]

Free Consultation

Get a free quote

About SUCONVEY

Leaders In Hot Splicing Machine

The SUH water-cooled vulcanizing machine is equipped with a water cooling circulation device. The heating plate has a fast cooling speed and can be disassembled in 5-10 minutes. Especially in hot weather, high temperature environment and tight construction period, the use of this water-cooled vulcanizing machine can improve work efficiency and shorten the construction period. The components of the SUH water-cooled vulcanizing machine are light and can be moved by workers. Before installation, the convenience of power and water sources should be taken into consideration. Use a special water pipe to connect the tap water source to the cooling water pipes of the upper and lower heating plates of the vulcanizing machine, but do not drain the water for the time being. At this time, the constant temperature starts until the vulcanization constant temperature time is over. At this time, open the tap water and pass water to the hot plate. When the temperature drops to the process specified value When the equipment is ready, the water can be released to disassemble the equipment, and the vulcanization operation is completed.

About Company

Benefits of Hot Splicing

Hot vulcanizing machines for conveyor belts offer several advantages that make them a preferred choice in the industry. One of the key benefits is the superior quality of the splice they provide. The high temperature and pressure used during hot vulcanization ensures a strong and durable bond between belt segments, resulting in improved overall conveyor performance and longevity.

Additionally, hot vulcanizing machines enable seamless splicing, eliminating potential weak points or bulges often associated with other splicing methods. This not only minimizes downtime for maintenance but also enhances operational safety by reducing the risk of unexpected belt failures. Furthermore, hot vulcanization allows for customization of splice configurations, catering to specific application requirements such as increased load-bearing capacity or resistance to abrasion, thereby enhancing the versatility and performance of conveyor systems.

About Design

How to buy the hot vulcanizing machine?

Our, Suconvey, innovative and high-quality hot vulcanizing machines are renowned in the industry for their durability, efficiency, and advanced technology. With a focus on continuous improvement and customer satisfaction, we have set itself apart as a key player in the market.

Before place one order, please confirm

- Conveyor belt width;

- Splice length;

- Bias Angle;

- Vulcanization pressure.

- Voltage

About Maintain

How to maintain vulcanizing machine

Maintaining and operating a hot vulcanizing machine is essential for ensuring the longevity and efficiency of rubber conveyor belt systems.

Regular inspection of the machine’s heating elements, pressure systems, and temperature controls is crucial to identify any potential issues before they escalate.

Additionally, maintaining proper alignment of the conveyor belts during the vulcanization process is vital for achieving uniform heat distribution and consistent bonding strength. It’s also important to follow manufacturer-recommended maintenance schedules for replacing heating elements, pressurization components, and temperature sensors to ensure optimal performance.

Furthermore, operators should be well-trained in using the hot vulcanizing machine to avoid unnecessary wear and tear on critical components. This includes understanding proper belt preparation techniques, recommended vulcanizing temperatures, and application methods for various types of rubber conveyor belts. Implementing proactive maintenance procedures will not only extend the service life of the hot vulcanizing machine but also contribute to improved productivity and reduced downtime in conveyor belt operations.

FAQ

Most frequent questions and answers

ask more question

The hot joint process of conveyor belts is a crucial aspect of maintaining and repairing these essential industrial components. This process involves the use of heat and pressure to join two ends of a conveyor belt together, ensuring a strong and durable connection. When executed properly, the hot joint process results in seamless integration, allowing the conveyor belt to function efficiently without any risk of separation or failure. It is a meticulous procedure that demands precision and expertise to achieve an optimal outcome.

One key element in the hot joint process is the selection of appropriate materials and adhesives. The type of rubber compound, fabric, and adhesive used can significantly impact the strength and longevity of the joint. Furthermore, precise temperature control during heating plays a critical role in ensuring that the materials bond effectively without causing any damage or weakening of the conveyor belt structure. Understanding these factors is essential for achieving reliable hot joints that withstand the rigors of continuous operation in various industrial environments.

In conclusion, mastering the hot joint process is paramount for industries reliant on conveyor systems to maintain smooth operations. By understanding its intricacies and investing in high-quality materials and skilled labor, businesses can ensure prolonged service life for their conveyor belts while minimizing downtime due to repairs or replacements. As technology continues to advance, it’s important for professionals in this field to stay informed about new techniques and innovations that can further enhance this vital aspect of conveyor belt maintenance.

There are several types of hot joint processes used for conveyor belts, each with its unique characteristics and benefits. The first type is the overlap welding process, which involves overlapping the two belt ends and using heat and pressure to fuse them together. This method provides a strong joint that can withstand heavy loads and tension.

Another popular hot joint process is the finger-overlap welding technique, which utilizes specially designed finger-like protrusions on the belt ends to create a seamless joint. This method offers excellent flexibility and reduces stress concentrations, making it suitable for applications requiring smooth belt transitions.

Lastly, the skiving process involves removing a portion of the belt’s top cover at an angle and then bonding the exposed layers. This results in a low-profile joint that minimizes interference with pulleys or other components along the conveyor system. Each of these hot joint processes has its advantages and is chosen based on specific application requirements and operational demands.

Before purchase: Give the most professional guide for choosing the right products or service system.

After purchase: Warranty for 1 or 2 years as the application and your requirements. Any damage will be repair or replace new during warranty as long as use the products as the right way and normal wear of the products apart from any break by personal reasons.

After-sale: Always give the most professional suggestions for the products working status, give support for customers marketing developments of own brand business. Always repair as long as we keep cooperation.