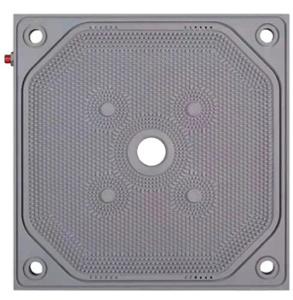

High Quality Customize Filter Press Plate Manufacturer

High-quality filter press plates ensure optimal filtration by providing uniform pressure on the filter cake, leading to maximum particle retention and consistently clear filtrate. These plates are designed to withstand high temperature and pressure conditions, making them durable and reliable for continuous operation. Additionally, advanced plate technologies have enabled manufacturers to produce plates with enhanced surface treatments that minimize clogging and improve overall efficiency.

Filter Plate for Filter Press Designer

Key Features

- Size: Available in sizes from 400mm to 2.1M X 2.1M, Rare Sized Filter Plates Available

- Standard size: 400, 470, 500, 630, 800, 915, 1000, 1200, 1400, 1500, 1500×2000 and 2000x 2000 mm

- Sludge inlet: Central inlet, decentralized inlet, corner inlet

- Material: Made with Durable Polypropylene, rubber, stainless steel, or cast iron

- Applications: Mining Industry, Chemical Industry, Industrial Industry, Food & Beverage Industry, Wastewater Industry

- Types of filter press plate:

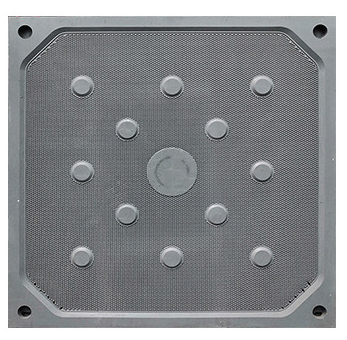

- Recessed Chamber filter press plate

- Non-gasketed recessed chamber filter press plate

- Plate and frame filter press plate

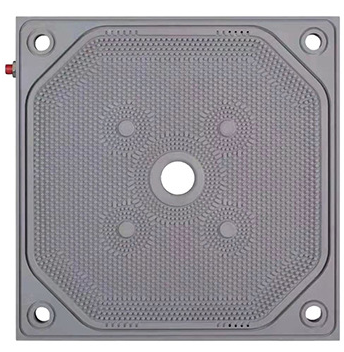

- Membrane squeeze filter press plate

- Key features:

- Chemical resistance: Strong corrosion resistance, resistant to acid, alkali and salt erosion to a certain extent

- Long service life: Reinforced polypropylene filter plate with stable chemical properties.

- Filter cloth support

- Temperature stability

- Various size available, can be customized

Types of Filter Press Plate

- 8 years manufacturing experience

- High Quality

- After-sales support services

- Standard and Strict Dimension

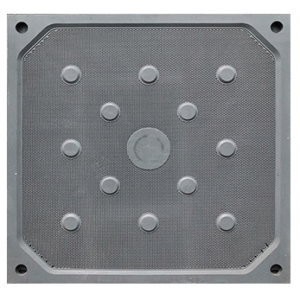

Polypropylene Filter Plate

Acid and alkali resistant

Plate and Frame Filter Plate

High and Low Temperature Resistant

Membrane Squeeze Filter Plate

Flexible cake thickness

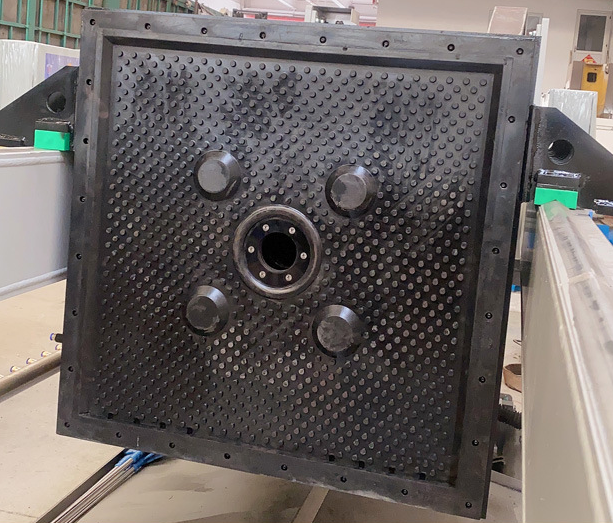

Rubber Filter Plate

Easy handling

Recessed Chamber Filter Plate

Automatic plate shifting possible

Customize Filter Plate

Lowest dewatering costs

Don’t Know What To Start With?

Get A Solution For Your Project

About Company

contact us

Suconvey Wholesale Can Be Easy & Safe.

No matter what kind of filter press plate you want, based on our extensive experience, we can manufacture and supply it for you.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Stephanie

- 86-13246961981

- [email protected]

Free Consultation

Get a free quote

About SUCONVEY

Leaders In Filter Press Plate

Our company’s journey in the manufacturing industry has been defined by a relentless pursuit of excellence and innovation. With decades of experience under our belt, we have honed our expertise in the production of high-quality filter press plates that are used across various industries. Our commitment to quality and precision has earned us a reputation as a trusted manufacturer, known for delivering products that meet and exceed the highest standards.

We pride ourselves on our ability to consistently adapt to evolving technological advancements, allowing us to stay ahead of the curve in an ever-changing market. Our team’s expertise is not only reflected in the superior quality of our filter press plates but also in our dedication to providing customized solutions tailored to meet the unique requirements of each client. Through continuous research and development, we have been able to innovate and optimize our manufacturing processes, resulting in products that offer unmatched performance and longevity.

About Company

Benefits of of high quality filter plates

High quality plates play a crucial role in the efficiency and effectiveness of filter press systems. These plates are designed to withstand high pressure and corrosion, ensuring optimal performance and durability. By using high quality plates, businesses can minimize downtime due to maintenance and replacements, leading to increased productivity and cost savings in the long run.

Moreover, high quality plates help achieve better filtration results by providing a uniform cake thickness and minimizing leakage during operation. This ensures that the final filtrate meets required standards and reduces product loss. In industries such as pharmaceuticals, food processing, and mining, where stringent filtration requirements are essential, investing in superior filter press plates is imperative for consistent and reliable production processes.

About Material

Superior materials for durable and efficient plates

High-quality materials are the foundation of durable and efficient filter press plates. As a high-quality filter press plate manufacturer, we understand the importance of using superior materials to ensure long-lasting performance. Our plates are crafted from premium polypropylene, which offers exceptional resistance to corrosion, abrasion, and chemical damage. This ensures that our plates can withstand the rigorous demands of filtration processes, providing reliable and consistent results over time.

Furthermore, the use of high-quality materials in filter press plates contributes to enhanced efficiency in filtration operations. The smooth surface and uniform structure of polypropylene allow for optimal cake release during the dewatering process, reducing cycle times and increasing productivity. Additionally, these superior materials enable our plates to maintain their integrity under high-pressure conditions, ensuring minimal maintenance requirements and extended service life. By prioritizing quality materials in our manufacturing processes, we strive to deliver unparalleled durability and efficiency for our customers’ filtration needs.

About Custom

Tailored solutions for specific filtration needs

When it comes to meeting specific filtration needs, one size definitely does not fit all. That’s why customizability is the name of the game when it comes to filter press plates. With tailored solutions, businesses can ensure that their filtration processes are optimized for maximum efficiency and effectiveness. Whether it’s a unique size requirement, special material considerations, or specific operating conditions, customization options allow for a precise fit that standard off-the-shelf options simply cannot provide.

By offering tailored solutions, filter press plate manufacturers empower businesses to address their unique challenges with confidence. This approach not only enhances performance but can also reduce downtime and maintenance costs by providing a solution that is specifically designed to meet the exact requirements of the application. From specialized coatings to custom configurations, the ability to customize filter press plates opens up a world of possibilities for industries looking to elevate their filtration processes beyond conventional standards.

FAQ

Most frequent questions and answers

ask more question

Filter press plates are a vital component in the filtration process, serving the purpose of separating solids from liquids. These plates come in various designs and materials, each tailored to specific industrial requirements. Understanding their purpose is crucial for optimizing filtration efficiency and achieving desired results.

The primary function of filter press plates is to provide a support structure for filter cloths while allowing the passage of filtrate through the cloth. This enables the retention of solids within the chamber formed by the plates, leading to efficient separation. It’s important to recognize that different plate types offer varying levels of filtration capacity and cake dryness, making it essential to select the right plates for specific applications. Overall, comprehending the purpose of filter press plates is instrumental in improving overall filtration performance and achieving cost-effective solutions for solid-liquid separation processes.

The design of filter press plates plays a crucial role in the efficient operation of the filter press. The plates are typically made from materials such as polypropylene, stainless steel, or cast iron, and their structure is carefully engineered to withstand the pressure and wear and tear involved in the filtration process. The overall function of the filter press plate design is to provide a solid platform for dewatering slurries and separating solids from liquids.

One key aspect of filter press plate design is the arrangement and size of feeding ports and discharge channels. These elements are strategically located to ensure even distribution of the slurry across the entire surface area of each plate, maximizing filtration efficiency. Additionally, some designs feature specialized recessed chambers that enhance cake formation and facilitate thorough dewatering. This attention to detail in plate design ultimately contributes to improved separation results and reduced cycle times, making it a vital consideration for any filtration system.

Applications of PP filter press plate:

Mining Industry: Tailings, Mineral Concentrates, Merrill-Crow, Coal, Aluminium, Precious Metals

Chemical Industry: Plastic, Resins, Paints , Dyes, Pigments

Industrial Industry: Metal Hydroxide, Phosphoric Acid, Silica

Food & Beverage Industry: Beer, Wine, Edible oils, Juice and more

Wastewater Industry: Municipal Water, Wastewater Treatment Plants

- Catalyst filtration and separation;

- High-temperature gas filtration in petrochemical industry, filtration of ebullated bed exhaust gas in petrochemical plants, filtration of catalytic cracking oil slurry;

- Purification of high-temperature flue gas in the metallurgical industry;

- Filtration of other high-temperature gases and liquids;

- Filtration of various high temperatures, corrosive liquids and catalysts in the petrochemical industry;

- Filtration and purification of various polymer melts in the chemical fiber film industry;

- Filtration and separation of various catalysts in the pharmaceutical industry;

- Used for gas distribution, corrugated bed orifice plate material;

- Used for high-pressure backwashing of oil filters, etc.;

- Used to filter edible oils, beverages and various edible slurries;

- Used to purify and filter production wastewater.

When it comes to filter press plates, the choice of materials plays a critical role in determining durability and performance. The most common types of materials used in filter press plates include polypropylene, cast iron, stainless steel, and rubber. Each material offers unique advantages and properties that cater to specific filtration needs. Polypropylene plates are lightweight, resistant to chemicals, and suitable for most standard applications, while cast iron plates are known for their high strength and temperature resistance. Stainless steel plates boast exceptional corrosion resistance and longevity, making them ideal for harsh or corrosive environments. Additionally, rubber-coated plates provide excellent sealing capabilities, preventing leakage during the filtration process.

Furthermore, the choice of material can impact the overall efficiency and cost-effectiveness of a filter press system. While polypropylene plates may offer affordability and versatility in filtration applications with moderate operating conditions, stainless steel or cast iron plates stand out as reliable choices for heavy-duty operations with demanding requirements such as high pressure or temperature tolerance. Overall, understanding the characteristics of each material is crucial in selecting the right filter press plate suited to specific industrial needs resulting in improved productivity and longevity.

Operating and maintaining filter press plates is a crucial aspect of ensuring efficient and effective filtration processes. To operate the plates, it is essential to first ensure that they are properly aligned and securely fitted within the filter press. This will help prevent leakage and maximize filtration efficiency. Additionally, proper operation involves regularly monitoring the pressure levels to prevent overloading the plates, which can lead to damage and decreased performance.

Maintenance of filter press plates includes regular cleaning to remove any build-up or debris that may affect their functionality. It is important to follow recommended cleaning procedures provided by the manufacturer, as using improper methods or chemicals can compromise the integrity of the plates. Furthermore, inspecting for any signs of wear and tear, such as cracks or warping, is crucial for identifying when replacement or refurbishment may be necessary. By adhering to proper operation and maintenance practices, filter press plate lifespan can be prolonged, reducing downtime and ensuring consistent filtration quality.

In conclusion, operating and maintaining filter press plates demands attention to detail and adherence to best practices. This not only ensures optimal performance but also extends the longevity of the equipment. Furthermore, incorporating routine maintenance into operational protocols can contribute to cost savings in the long run by minimizing repair costs and enhancing overall productivity within industrial filtration processes.