Soft Flexible Silicone Rubber Tubing

Soft Flexible Silicone Rubber Tubing Manufacturer

Soft flexible silicone rubber tubing is designed for applications where high flexibility, elastic recovery and long-term stability are critical.

Customers typically choose this type of silicone tubing when rigid plastics or stiff rubber hoses fail to perform under bending, vibration or temperature variation.

At Suconvey, we supply soft silicone rubber tubing that remains consistently flexible, easy to install and dependable across a wide range of industrial, laboratory and equipment-level applications.

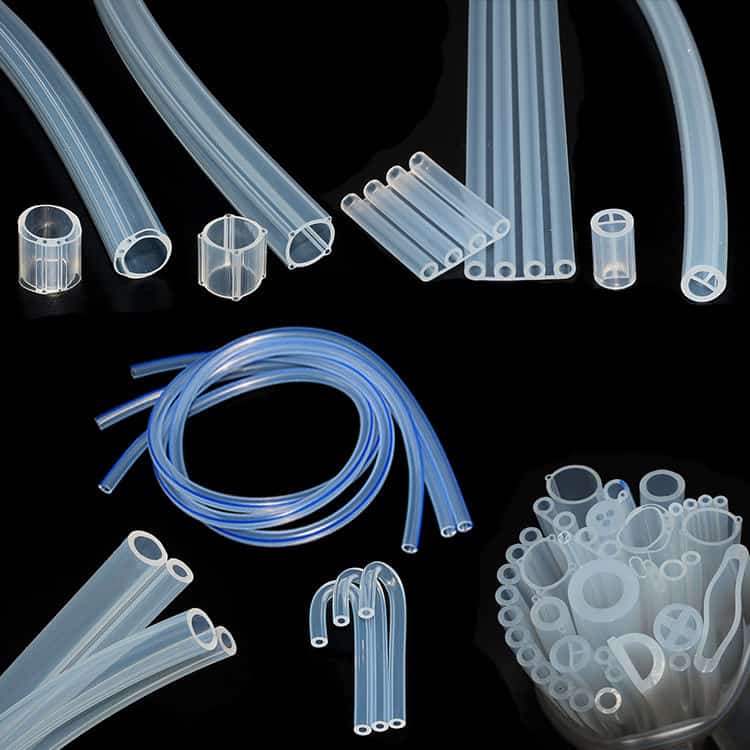

Soft Flexible Silicone Rubber Hose

Soft flexible silicone rubber tubing is made from low-to-medium hardness silicone elastomer, formulated to provide:

- High elasticity

- Smooth inner surface

- Excellent recovery after compression or bending

- Stable performance over time

From a customer’s perspective, this means the tubing does not kink easily, does not permanently deform, and continues to seal and function even after repeated movement or pressure changes.

Unlike many thermoplastics, silicone rubber maintains flexibility without becoming brittle or sticky, even when exposed to heat, cold or aging environments.

Product Details

Super Soft Silicone Tubing Supplier

Key Features

Exceptional Flexibility in Tight Spaces: Soft silicone tubing bends easily around corners, fittings and compact assemblies.

Elastic Recovery Under Repeated Stress: After compression, stretching or vacuum draw, silicone tubing quickly returns to its original shape.

Wide Temperature Tolerance: Typical operating range is approximately −60°C to +200°C, allowing use in: cold start environments, warm processing areas, temperature-cycling systems. The tubing remains flexible across this range rather than hardening or softening excessively.

Clean, Inert & Easy to Maintain: Soft silicone rubber tubing does not impart taste or odor and is easy to clean.

China Soft Flexible Silicone Rubber Tubing Manufacturer

Technical Specifications

| Soft Flexible Silicone Rubber Tubing – Typical Specifications | |

|---|---|

| Material | Soft silicone elastomer |

| Hardness | Shore A 30 – 80 |

| Temperature Range | −60°C to +250°C |

| Inner Diameter (ID) | 1 mm – 100 mm (custom available) |

| Outer Diameter (OD) | 2 mm – 120 mm |

| Wall Thickness | 0.5 mm – 10 mm |

| Flexibility | Excellent elastic recovery |

| Chemical Resistance | Good resistance to many fluids |

| Available Forms | Coils, cut lengths, OEM packaging |

Expanded Applications

Laboratory & Analytical Equipment

- Suction and transfer lines

- Instrument connection tubing

- Sampling and waste lines

- Flexibility allows easy routing inside compact lab devices without stressing connectors.

Fluid Handling & Process Systems

- Low-pressure fluid transfer

- Peristaltic pump tubing (non-reinforced versions)

- Manifold and distribution lines

- Silicone tubing’s smooth bore supports stable flow and easy cleaning.

Vacuum & Low-Pressure Applications

- Although not the product name, many customers use soft silicone tubing in:

- vacuum pumps

- suction systems

- pressure sensing lines

Instrumentation & Automation

- Pneumatic control lines

- Sensor protection sleeves

- Flexible interconnections between moving parts

- The tubing absorbs vibration and reduces mechanical fatigue.

Why Choose Suconvey?

Suconvey provides more than just tubing — we offer engineering support, quality assurance and tailored supply solutions to help your project succeed:

---Deep Material Expertise

- Over 10+ years specializing in silicone tubing and hose for industrial, food, beverage and pharmaceutical markets.

- Understand performance tradeoffs for tubing under temperature, pressure, flex cycles and hygiene requirements.

---Custom Design Support

- Size optimization for flow rates and installation space

- Material selection (solid vs sponge) based on media, pressure and cleaning methods

- Surface finish that supports CIP/SIP sanitation

- Wall thickness vs flexibility design for bend radius and abrasion resistance

---Quality from Raw Material to Delivery

- Certified food-grade silicone (FDA) compounds

- Controlled extrusion to maintain tight tolerances

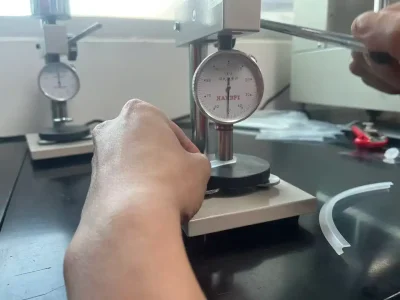

- In-house inspection for wall thickness, inner/outer diameter and surface quality

- Batch traceability for consistency and audit support

---Flexible MOQ & Sample Support

- Support small and pilot orders before production scaling

- Quick turn pre-production samples to verify fit and performance

- Customized packaging and labeling per project needs

---Global Supply & On-time Delivery

- Efficient logistic planning to keep your production on schedule

- Export packing optimized for protection, cleanliness and traceability

How to Select the Right Soft Silicone Rubber Tubing

1. Inner Diameter (ID)

Match the ID to your fitting or interface to avoid leakage, turbulence or dead volume.

2. Wall Thickness

Thicker walls handle pressure and vacuum better; thinner walls offer greater flexibility.

Choose based on your system’s mechanical demands.

3. Hardness (Shore A)

Softer tubing = easier bending

Harder tubing = better shape retention

We can adjust hardness to suit your balance of flexibility and strength.

4. Temperature & Media

Always consider both operating temperature and the fluids or gases involved.

We can recommend compound adjustments if chemical exposure is a concern.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone tubes are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test tubes can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Related Products

Frequently Asked Questions

If your question is not listed, please contact us.

Yes, it is commonly used in low to moderate vacuum applications. For deep vacuum or high pressure, reinforced tubing may be recommended.

No. Soft silicone rubber tubing has excellent bend recovery and resists kinking better than many plastic alternatives.

Yes. It is widely used for air, water and compatible fluids. Always confirm chemical compatibility for aggressive media.

Absolutely. We offer custom ID, OD, wall thickness and color options based on your requirements.

Service life depends on temperature, media and mechanical stress, but silicone generally outlasts many conventional rubber and plastic tubes under similar conditions.

MOQ: Flexible, often low quantity support to help prototyping or small runs

Sample Lead Time: 1–3 business days for standard sizes

Production Lead Time: Depends on size and order volume, typically 1–3 weeks

Contact Us

High Pressure Silicone Vacuum Tubing

We are the professional High Pressure Silicone Vacuum Tubing manufacturer in China. A variety of applications use silicone vacuum hose because of its ability to resist extreme temperatures and pressures. This type of hose is often used in medical settings and in the food and beverage industry due to its resistance to chemicals and high temperatures. In the automotive industry, silicone vacuum hose is often used to connect parts that need a tight seal, such as the engine and transmission. Its flexibility and durability make it resistant to kinking, crushing, and abrasion.

High Pressure Silicone Vacuum Tubing mANUFACTURER

Key Features

- Ideal for high-pressure applications

- High Tear Strength and easy to clean

- Wide functioning temperature range

- Offers excellent flexibility, compression set and resiliency

- Durable, Heavy-Duty & Dependable

- UV,Ozone and Other Chemical Resistant

- Using imported silicone raw materials

Our service

- Cut to size

- On-time Dispatch Guarantee

- Custom packaging with special logo

- Supply free samples and design drawing

- Customize the size, thickness, color, hardness as you need

Applications

- Transfer for Food Factory & Drink & Pharmaceutical Industry

- Lighting and Construction

- Dairy, Automotive and Aerospace

- Hydraulic appliance, pneumatic machine

- Other industrial and commercial applications

Silicone Rubber Tubes Parameter

Item | Data | Item | Data |

Thickness | 0.1mm~30mm | Diameter | 0.3mm~150mm |

Length | Endless | Specific Gravity | 0.2g/cm3~1.3g/cm3 |

Shape | T/D/P or design | Material | Solid Silicone,Sponge silicone |

Function | Dust/water proof, noise/ shock reduction | Resistant | Oil, chemical, heat |

Color | Pantone Card and transparent | Hardness | 20~90 Shore A |

Appearance | Smooth/Wave/Braided | Temperature | -60℃-350℃ |

Tear Strength | Up to 12 Mpa | Elongation | 300-650% |

Deformation Rate | ≤9% | Anti-Flammable | UL 94 – V0 |

Acid and Alkali Resistance | Available | Insert Layer | Fabric or Canvas |

Chemical Safe | ROHS | Food Grade | FDA Approved |

Medicine | Passed Halogen Test | Water Absorption | 20% for silicone, 80% for sponge |

Silicone Hoses Standard Size Supply

Thickness | ID/OD | Color | Hardness |

T: Custom | ID: Custom | Transparent | 20 Shore A |

T: 0.5mm to 15mm | ID: 5-150mm/OD: 6-180mm | Translucent | 25 Shore A |

T: 1mm | ID: 2mm/OD: 4mm | Red | 30 Shore A |

T: 2mm | ID: 6mm/OD: 8mm | Black | 40 Shore A |

T: 3mm | ID: 8mm/OD: 14mm | White | 50 Shore A |

T: 4mm | ID: 10mm/OD:18mm | Orange | 60 Shore A |

T: 5mm | ID: 20mm/OD: 30mm | Blue | 65 Shore A |

T: 8mm | ID: 50mm/OD: 66mm | Green | 70 Shore A |

T: 10mm | ID: 100mm/OD: 120mm | Clear | 80 Shore A |

T: 15mm | ID: 150mm/OD: 180mm | Grey | 90 Shore A |

Contact: Stephanie ; WhatsApp: +86 13246961981; E-Mail: [email protected]

High QUality Silicone Rubber tubes FOR SALE

Suconvey silicone rubber tube is completely resistant to chemicals, highly resistant to weathering, UV, and ozone, very flexible, and extremely durable. There are many properties that make silicone vacuum hose ideal for high-pressure applications. First, silicone vacuum tube is very strong and durable. It can withstand high temperatures and pressures without breaking or leaking. Second, silicone vacuum tube is flexible and can be bent or shaped into different configurations. Finally, silicone is non-reactive and does not interact with other materials.

- 8 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

Suconvey Rubber Factory Supplys Custom Special Silicone Rubber Tubes

We have developed a series of high quality, high performance silicone rubber sheet, silicone tube, silicone gasket seals, silicone rubber roller, custom silicone rubber profiles and so on. Our Class VI silicone products features the characteristic of nontoxic, high temperature, slow aging, heat-press, wear abrasive, high and low density and flame retardant.

No matter how big or small the project is you can trust our expert craftsmen to deliver on time .

Professional high pressure silicone tubing manufacturer

We are a leading Manufacturer of high pressure silicone vacuum tubing from China. High pressure silicone vacuum hose is used in a variety of industries. It has a wide range of applications due to its unique properties. The hose is made of silicone, which gives it its flexibility and strength. The hose is also resistant to high temperatures and pressures.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Contact Us For More spec silicone rubber extrusion Types

Share your thoughts and customize your target products with our silicone rubber specialist.

Frequently asked questions

Here are the most frequently asked questions and answers about how to buy customized silicone products

- Please confirm your inquiry request as the usefulness.

- Please measure your application place size and count the quantity. If you have drawing, better send to us. If you have no drawing please tell me your application and tell me where do you want to use it, better to know the application equipment model, we can make drawing or solutions for you.

- We will making drawing as your demands or required products photos or pictures.

- Please confirm the size and quantity, especially the specifications of what you want so that I can supply the most precise guide and suggestions.

- Making samples as your exact requirements and appplications.

- Testing and confirm the samples and making upgrade if necessary.

- Placing order and prepare the production.

- Arrange the delivery after out of warehouse test.

- After-sale service follow the goods always.

Before purchase: Give the most professional guide for choosing the right products or service system.

After purchase: Warranty for 1 or 2 years as the application and your requirements. Any damage will be repair or replace new during warranty as long as use the products as the right way and normal wear of the products apart from any break by personal reasons.

After-sale: Always give the most professional suggestions for the products working status, give support for customers marketing developments of own brand business. Always repair as long as we keep cooperation.

Yes, we can provide existing sample for free, but a little sample charge for custom design, new customers are expected to pay for the delivery cost, the sample charge will be deducted from the payment for formal order.

For existing product, it takes 1-2 days; If you want your design, it may take 3-5 days depends on your design content.

We have our QC department empowered with a professional QC team. “Quality First, Cutomer Focus” is our quality policy, and we have Incoming Quality Control / In-process Quality Control / Out-going Qualtiy Control throughout our factory operations.

To withstand all the above extreme working environment requirements, Suconvey has to choose the best quality raw materials which can not only produced good performance silicone products but also have many outstanding advantages such as will not change to yellow even use for a long time, will not become brittle easily broken, will not shrink or expand although using for a long time, will also not easily change the specification to influence your machine operation. Only based on the above quality control, silicone products can be serviced for a long time to save your energy to replace them and your time waiting for the replacement so that the productivity is high.