High Temperature Silicone Tubes

High Temperature Silicone Tubing Manufacturer

Whether you’re dealing with industrial ovens, hot fluid transfer, thermal processing equipment, or extreme environment wiring, high temperature silicone tubing is a practical solution when ordinary elastomers fail.

At Suconvey, our high temperature silicone tubes are designed for engineers and procurement teams who need tubing that stays flexible, robust and resistant under extended high heat exposure, while also offering reliable chemical and electrical performance.

High Temperature Silicone Rubber Hose

High temperature silicone tubing is a flexible elastomer tube made from specially formulated silicone compounds that can endure sustained elevated temperatures without embrittling, softening or degrading.

Unlike standard rubber or thermoplastic tubing, high temperature silicone maintains:

- Elastic flexibility at high temperatures

- Low compression set under thermal load

- Resistance to thermal cycling and aging

- Stable electrical insulation in heat-stressed environments

In practice, this means you don’t have to worry about tubing hardening, cracking or needing frequent replacement in hot environments.

Product Details

High Temperature Silicone Rubber Hose Supplier

Key Features

- Extended Thermal Capability: Customers see reliable performance from approximately -60°C to +250°C continuous, and even short excursions above this, depending on compound selection.

- Mechanical Flexibility Under Heat: Unlike many materials that become stiff at high temperatures, silicone tubing stays flexible and resilient, reducing mechanical fatigue and preventing micro-cracks from repeated flexing.

- Resistant to Aging, UV & Weather: For outdoor or tropical environments, silicone tubing resists: UV radiation, Ozone attack, Oxidative aging

- Chemical & Fluid Compatibility: While not immune to all chemicals, high temperature silicone tubing resists many oils, coolants, mild acids and alkalis typically encountered in industrial environments, making it a versatile protection solution.

China High Temperature Silicone Tubing Manufacturer

Technical Specifications

| High Temperature Silicone Tubing – Typical Specifications | |

|---|---|

| Material | High temperature silicone elastomer |

| Temperature Range | −60°C to +250°C (continuous) |

| Hardness | Shore A 20–90 |

| Wall Thickness | 0.5 mm – 10 mm |

| Inner Diameter | 1 mm – 50 mm |

| Outer Diameter | 2 mm – 60 mm |

| Color | Red, Black, Clear, Custom |

| Resistance | UV, ozone, heat, mechanical flex |

| Available Forms | Coils, cut lengths, OEM packaging |

Expanded Applications

Industrial Processing & Thermal Equipment

In ovens, dryers, convection heaters, curing lines and kilns, ambient temperatures often exceed the limits of ordinary tubing. Silicone tubing bridges that gap with reliable flexibility.

Common uses:

- Sensor wiring protection near heat sources

- Cable insulation alongside ovens or hot hoods

- Tubing for pneumatic or vacuum lines near heat zones

Food, Beverage & Pharmaceutical Processes

For systems with heated transfer lines, CIP/SIP cycles or thermal cleaning, high temperature silicone tubing supports:

- Hot fluid transfer such as steam or heated water

- Temperature tolerance during sanitation

- Compliance-friendly contact surfaces when required

Automotive & Transportation

In engine compartments and exhaust-adjacent systems where heat, vibration and movement combine, silicone tubing helps:

- Protect wiring harnesses from heat soak

- Insulate sensors and connectors

- Extend system uptime

Electronics & Power Systems

Wherever electrical insulation must be maintained under temperature stress — like power conversion units, inverters, or industrial controllers — silicone tubing maintains dielectric strength and mechanical integrity.

Why Choose Suconvey?

Suconvey provides more than just tubing — we offer engineering support, quality assurance and tailored supply solutions to help your project succeed:

---Deep Material Expertise

- Over 10+ years specializing in silicone tubing and hose for industrial, food, beverage and pharmaceutical markets.

- Understand performance tradeoffs for tubing under temperature, pressure, flex cycles and hygiene requirements.

---Custom Design Support

- Size optimization for flow rates and installation space

- Material selection (solid vs sponge) based on media, pressure and cleaning methods

- Surface finish that supports CIP/SIP sanitation

- Wall thickness vs flexibility design for bend radius and abrasion resistance

---Quality from Raw Material to Delivery

- Controlled extrusion to maintain tight tolerances

- In-house inspection for wall thickness, inner/outer diameter and surface quality

- Batch traceability for consistency and audit support

---Flexible MOQ & Sample Support

- Support small and pilot orders before production scaling

- Quick turn pre-production samples to verify fit and performance

- Customized packaging and labeling per project needs

---Global Supply & On-time Delivery

- Efficient logistic planning to keep your production on schedule

- Export packing optimized for protection, cleanliness and traceability

How to Select the Right High Temperature Silicone Tube

Temperature Profile

Estimate how hot the local environment gets — both during idle and active processing — and choose tubing that stays flexible across that range.

Inner & Outer Diameters

Match tubing ID to your part or conduit size before heat. Tubing should fit without force before heat is applied.

Wall Thickness

Thicker walls give more protection, but can reduce flexibility. Choose based on:

- mechanical protection

- insulation requirement

- required bend radius

Compliance Needs

If the system interacts with food, beverage or clinical elements, specify any regulatory criteria (e.g., FDA compliant compounds) early so appropriate silicone can be selected.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

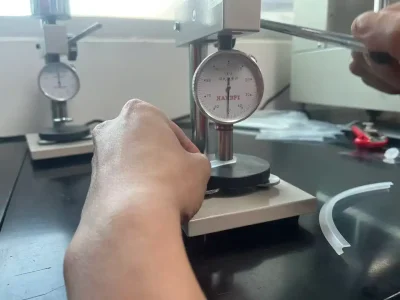

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone tubes are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test tubes can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Related Products

Frequently Asked Questions

If your question is not listed, please contact us.

Yes. High temperature silicone tubing retains flexibility and structural integrity in continuous elevated temperature environments up to around +250°C, far beyond most polymer alternatives.

Yes. Silicone’s UV and ozone resistance makes it well suited for outdoor applications where enduring sunlight and environmental stress is a concern.

While high temperature silicone tubing can be used as protective outer sheathing, actual fluid transfer depends on the specific silicone grade and the fluid type. We can advise on compound selection for your media.

Yes. We support custom ID/OD, wall thickness and color options to meet your specific design or assembly requirements.

Soft flexible tubing focuses on bendability at lower temperature ranges, while high temperature tubing prioritizes thermal stability under heat stress. If your system regularly sees hot zones, high temperature silicone is the right choice.

MOQ: Flexible, often low quantity support to help prototyping or small runs

Sample Lead Time: 1–3 business days for standard sizes

Production Lead Time: Depends on size and order volume, typically 1–3 weeks