Soft Silicone Sponge & Foam Tubes — Flexible, Compressible, High-Performance

Flame Resistant Silicone Foamed Tube Manufacturer

Soft silicone sponge and foam tubes (also called silicone foam tubing) are designed for applications where cushioning, light weight, compressibility and sealing are needed along with the traditional advantages of silicone rubber.

Whether your system needs shock absorption, seal integrity under compression, weight savings or thermal insulation, silicone sponge tubes deliver combinations of performance that ordinary solid rubber tubes cannot.

At Suconvey, we manufacture custom silicone sponge & foam tubes that are:

🔥 Lightweight yet durable

🧠 Highly compressible and resilient

🌡️ Thermally stable across wide temperature ranges

💧 Low moisture absorption

🔄 Excellent recovery after repeated compression

Soft Silicone Sponge & Foam Tubes

Silicone sponge and foam tubes are produced by introducing a controlled cellular structure into the silicone elastomer during processing.

This structure creates a tube that is:

- soft and compressible

- lightweight

- flame retardant

- resilient after repeated compression

- stable across a wide temperature range

When installed between components or around edges, the tube compresses evenly and recovers reliably, helping maintain contact pressure and dimensional stability over time.

Unlike many organic foam materials, silicone-based sponge structures do not rely on plasticizers or fillers to achieve softness, which contributes to better aging resistance and safer behavior under heat exposure.

Product Details

Heat Resistant Silicone Foamed Tubes Supplier

Key Features

Comfortable Compression & Recovery: The soft cellular structure allows the tube to compress easily under load while returning close to its original shape when the load is removed.

This is especially useful for seals, buffers and interfaces where uniform contact pressure is needed without excessive force.

Lightweight Structure with Thermal Stability: Foamed silicone reduces material density while retaining silicone’s inherent resistance to temperature extremes.

Stable Behavior Near Heat Sources: Silicone sponge tubing remains elastic and dimensionally stable in both cold and warm environments.

Weathering, UV & Aging Resistance: The silicone backbone resists UV, ozone and environmental aging, making sponge tubes suitable for indoor and outdoor installations where long service life is expected.

China Fire Resistant Silicone Sponge Hose Manufacturer

Technical Specifications

| Silicone Sponge & Foam Tubes – Typical Specifications | |

|---|---|

| Material | Silicone elastomer with cellular sponge structure |

| Temperature Range | −60°C to +200°C |

| Hardness | Shore C 10 – 50 (density dependent) |

| Inner Diameter (ID) | 2 mm – 120 mm (custom available) |

| Outer Diameter (OD) | 3 mm – 150 mm |

| Wall Thickness | 1 mm – 15 mm |

| Density | Lightweight sponge / foam structure |

| Compression Recovery | Excellent elastic rebound |

| Weather & UV Resistance | Excellent |

Expanded Applications

Sealing & Gasket Interfaces

Soft silicone sponge tubes are often used as:

- dynamic compression seals

- door and panel gasket buffers

- edge seals in enclosures

- cushion-to-surface seals

- Their ability to compress and spring back ensures consistent seal force and low creep.

Vibration & Shock Absorption

In machines with moving parts, sensitive instrumentation, or vibration sources, silicone foam tubing can:

- damp vibration

- reduce resonance

- protect electronics

- From robotics to HVAC systems, this reduces wear and noise.

Thermal Barriers & Insulation

Because sponge silicone traps air in its cells, it provides thermal barrier properties useful in:

- furnace edges

- hot fluid channels

- insulation of heated tubing

- This helps reduce thermal transfer and protect sensitive components.

Lightweight Fabrication Solutions

Where weight matters — such as in aerospace, automotive interiors or portable equipment — silicone foam tubing delivers performance without the weight penalty of solid rubbers.

Why Choose Suconvey?

Suconvey provides more than just tubing — we offer engineering support, quality assurance and tailored supply solutions to help your project succeed:

---Deep Material Expertise

- Over 10+ years specializing in silicone tubing and hose for industrial, food, beverage and pharmaceutical markets.

- Understand performance tradeoffs for tubing under temperature, pressure, flex cycles and hygiene requirements.

---Custom Design Support

- Size optimization for flow rates and installation space

- Material selection (solid vs sponge) based on media, pressure and cleaning methods

- Surface finish that supports CIP/SIP sanitation

- Wall thickness vs flexibility design for bend radius and abrasion resistance

---Quality from Raw Material to Delivery

- Certified food-grade silicone (FDA) compounds

- Controlled extrusion to maintain tight tolerances

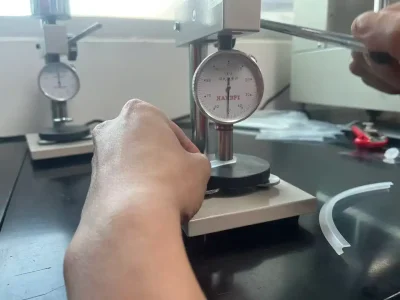

- In-house inspection for wall thickness, inner/outer diameter and surface quality

- Batch traceability for consistency and audit support

---Flexible MOQ & Sample Support

- Support small and pilot orders before production scaling

- Quick turn pre-production samples to verify fit and performance

- Customized packaging and labeling per project needs

---Global Supply & On-time Delivery

- Efficient logistic planning to keep your production on schedule

- Export packing optimized for protection, cleanliness and traceability

Soft Silicone Sponge vs Solid Silicone Tubing — When to Use Which

| Feature | Silicone Sponge Tube | Solid Silicone Tube |

|---|---|---|

| Compressibility | ★★★★ (High) | ★☆☆☆ (Low) |

| Cushioning / Shock Absorption | ★★★★ | ★☆☆☆ |

| Weight | ★★★★ (Light) | ★★☆☆ (Heavier) |

| Seal Performance (Compression) | ★★★★ | ★★☆☆ |

| Thermal Insulation | ★★★★ | ★★☆☆ |

| Mechanical Strength | ★★☆☆ | ★★★★ |

| Abrasion Resistance | ★★☆☆ | ★★★★ |

When to choose sponge/foam tubing:

✔ Cushioning or seal compression

✔ Lightweight assemblies

✔ Insulation under thermal cycling

✔ Buffering or vibration isolation

When to choose solid silicone tubing:

✔ Pressure or fluid transfer

✔ High abrasion environments

✔ Cable protection without compression

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone tubes are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test tubes can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Related Products

Frequently Asked Questions

If your question is not listed, please contact us.

In most contexts they are used interchangeably. “Sponge” emphasizes a closed-cell foam with better compression sealing; “foam” can be open- or closed-cell depending on design. We can tailor cell structure based on your needs.

Yes, they are excellent for compression sealing when a soft, conforming surface is required between mating parts.

Silicone sponge is typically closed-cell, meaning very low water absorption. However, specifics depend on cell design — we can advise based on your media.

Soft cells and lower Shore A are better for sealing and cushioning; firmer combinations are better for structural support under compression. Share your compression gap and load and we’ll recommend options.

Absolutely. We support custom ID/OD, wall thickness and lengths per your design or application specification.

MOQ: Flexible, often low quantity support to help prototyping or small runs

Sample Lead Time: 1–3 business days for standard sizes

Production Lead Time: Depends on size and order volume, typically 1–3 weeks