Braid Reinforced Silicone Rubber Hoses — High Strength, Pressure

Braided Reinforced Silicone Tubing Manufacturer

Braid reinforced silicone rubber hoses are engineered to provide enhanced strength, superior flexibility and reliable performance in demanding environments where standard silicone tubing would fail.

By combining a durable silicone elastomer body with an embedded reinforcing braid (often polyester, nylon or fiberglass), these hoses deliver improved pressure handling, reduced elongation under load, and greater dimensional stability.

Suconvey’s braid reinforced silicone hoses are ideal for applications in industrial automation, pneumatics, fluid transfer systems, HVAC, electrical insulation conduits and machinery assemblies where strength and flexibility must coexist.

FDA Approved Braided Reinforced Silicone Tubing

Silicone rubber has excellent temperature tolerance, chemical resistance and flexibility, but without reinforcement it can stretch or deform under pressure or mechanical load.

A braid reinforced silicone hose integrates one or more layers of high-strength fiber braid inside the silicone wall, enabling the hose to handle higher operating pressures, maintain shape under load and resist burst or elongation.

The result is a hose that combines:

✔ silicone’s thermal and chemical stability

✔ enhanced mechanical strength from the braid layer

✔ consistent performance under dynamic bending

✔ reduced risk of hose collapse or over-elongation

Product Details

FDA Approved Braided Reinforced Silicone Tubing Supplier

Key Features

High Pressure Handling Capability: Unlike plain silicone tubes, braided hoses can withstand higher internal and external pressure without ballooning or loss of cross-sectional shape.

Enhanced Mechanical Strength: The embedded braid significantly increases: tensile strength, resistance to elongation, resistance to abrasion from internal flexing.

Retained Flexibility and Bend Radius: Despite added strength, braided silicone hoses stay flexible.

Wide Temperature and Environmental Range: the reinforced hose maintains performance across a wide temperature band, typically -60°C to +200°C (depends on compound and braid type).

Chemical Resistance and Durability: Silicone resists many chemicals, oils and aqueous environments better than many other elastomers.

High Pressure Braid Reinforced Silicone Hose Manufacturer

Technical Specifications

| Braid Reinforced Silicone Rubber Hoses – Typical Specifications | |

|---|---|

| Material | Silicone rubber with embedded fiber braid |

| Reinforcement | Polyester / Nylon / Fiberglass / Aramid |

| Temperature Range | −60°C to +200°C (dependent on compound) |

| Hardness | Shore A 40 – 90 |

| Inner Diameter (ID) | 6 mm – 100 mm (custom available) |

| Outer Diameter (OD) | 10 mm – 120 mm |

| Designed Operating Pressure | Dependent on braid type and layer count |

| Flexibility | Excellent bend performance |

| Chemical Resistance | Resistant to many fluids and cleaning agents |

| Available Forms | Coils, cut lengths, OEM packaging |

Typical Applications

Pneumatic Systems & Compressed Air Lines

Braid reinforced silicone hoses provide stable pressure handling and vibration resilience in pneumatic actuator lines, air tools and pressure manifolds.

Fluid Transfer & Process Systems

When liquids are being moved under pressure, the braided structure helps maintain hose integrity, reducing the risk of bulging or hose failure over time.

HVAC & Industrial Equipment

From air conditioning systems to industrial blowers, these hoses help move air and gas while resisting temperature and mechanical stress.

Automotive, Rail & Heavy Machinery

- Coolant or heater circuits

- Vibration-tolerant routing

- Resilient connection paths in hot engine areas

Electrical Conduit & Protective Sleeving

When wiring needs a flexible sleeve that resists heat and mechanical abrasion, braid reinforced silicone hoses can serve as protective conduits that also absorb movement.

Why Choose Suconvey?

Suconvey provides more than just tubing — we offer engineering support, quality assurance and tailored supply solutions to help your project succeed:

---Deep Material Expertise

- Over 10+ years specializing in silicone tubing and hose for industrial, food, beverage and pharmaceutical markets.

- Understand performance tradeoffs for tubing under temperature, pressure, flex cycles and hygiene requirements.

---Custom Design Support

- Size optimization for flow rates and installation space

- Material selection (solid vs sponge) based on media, pressure and cleaning methods

- Surface finish that supports CIP/SIP sanitation

- Wall thickness vs flexibility design for bend radius and abrasion resistance

---Quality from Raw Material to Delivery

- Certified food-grade silicone (FDA) compounds

- Controlled extrusion to maintain tight tolerances

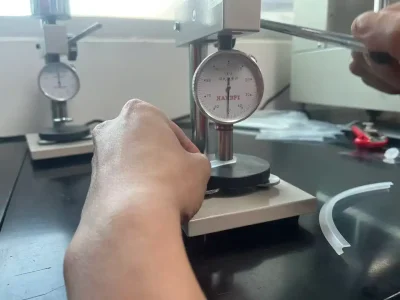

- In-house inspection for wall thickness, inner/outer diameter and surface quality

- Batch traceability for consistency and audit support

---Flexible MOQ & Sample Support

- Support small and pilot orders before production scaling

- Quick turn pre-production samples to verify fit and performance

- Customized packaging and labeling per project needs

---Global Supply & On-time Delivery

- Efficient logistic planning to keep your production on schedule

- Export packing optimized for protection, cleanliness and traceability

How to Choose the Right Braid Reinforced Silicone Hose?

1. Operating Pressure Range: Determine maximum pressure the hose must withstand. Braid layers provide enhanced strength, and we can adjust braid density for higher requirements.

2. Temperature Range: Identify both the minimum and maximum temperatures encountered in your system. Our silicone compounds maintain flexibility and integrity across a wide range.

3. Hose Diameter & Flow Requirements: Provide the inner diameter (ID) needed for your system’s flow rate, and we will match the braid reinforcement to maintain dimensional stability.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone tubes are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test tubes can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Related Products

Frequently Asked Questions

If your question is not listed, please contact us.

Braided silicone offers higher pressure resistance and lower elongation under load, while retaining flexibility, making it superior for dynamic and pressure-exposed applications.

Common braid materials include polyester, nylon, fiberglass and aramid, each offering different strength, abrasion resistance and thermal characteristics. We can tailor based on your needs.

Yes — depending on braid density and wall thickness, they can function reliably in low-pressure/vacuum applications as well as positive pressure environments.

Absolutely. Silicone’s inherent weather, UV and ozone resistance, combined with braid strength, makes these hoses durable outdoors.

Yes. We support custom inner diameters, wall thicknesses, braid selections, and cut-to-length orders to fit your exact specifications.

MOQ: Flexible, often low quantity support to help prototyping or small runs

Sample Lead Time: 1–3 business days for standard sizes

Production Lead Time: Depends on size and order volume, typically 1–3 weeks