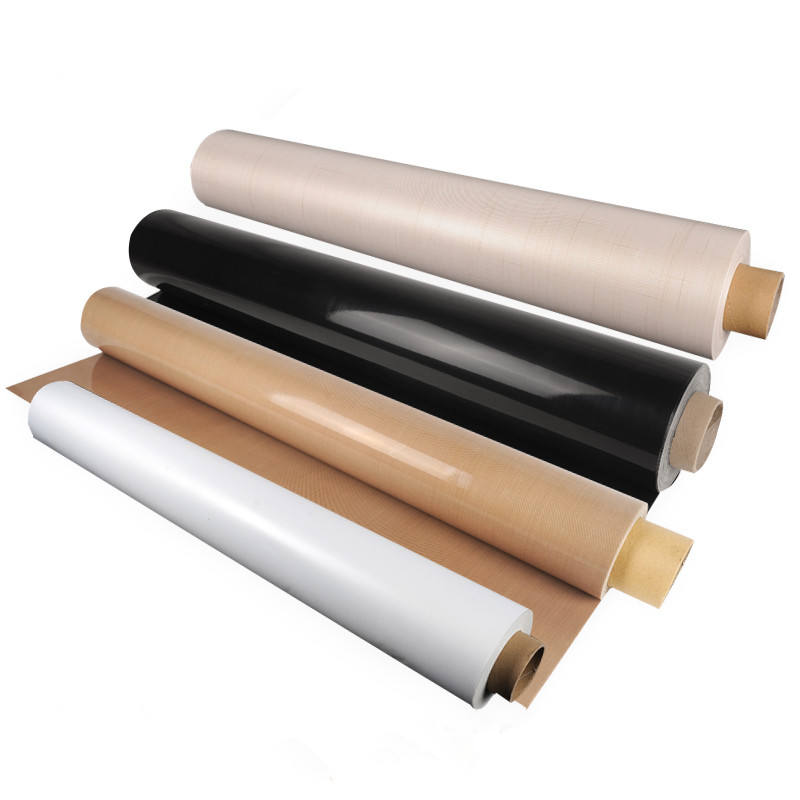

PTFE Coated Fiberglass Fabric Back Adhesive With Release Paper

Back Adhesive PTFE Coated Fiberglass Film Manufacturer

Key Features

- Used in packaging, thermoplastic, composite, heat sealing, electronic and electrical industries

- Smooth surface, good stability, waterproof

- Low friction coefficient

- The best choice for oil-free self-lubrication

- Stable size, high strength, elongation coefficient less than 5%

- High insulation performance, fire retardant

- Strong adhesive, tear off no residual glue

- High and low temperature resistance

- Resistance to chemical corrosion, strong acid, alkali and all kinds of organic solvent corrosion

Our service

- Cut to size

- On-time Dispatch Guarantee

- Supply free samples and design drawing

- Customize the size, shape, color, thickness, and functionality as you need

- Read more PTFE Teflon products

PTFE Fiberglass Film and Tape with Adhesive Data | ||||||

Item | Thickness | Width | Weight | Tensile Strength | Temperature | Color |

mm | mm | g/sqm | N/5cm | °C | Brown Black White Beige | |

SUC008 | 0.08±0.0005 | 1250mm | 150 g/sqm | 550/450N | -60-260°C | |

SUC008B | 0.08±0.0005 | 1250mm | 150 g/sqm | 550/450N | -60-260°C | |

SUC008W | 0.08±0.0005 | 1350mm | 150 g/sqm | 550/450N | -60-260°C | |

SUC013 | 0.13±0.0005 | 1500mm | 250 g/sqm | 1100/1000N | -60-260°C | |

SUC013B | 0.13±0.0005 | 1250mm | 250 g/sqm | 1100/1000N | -60-260°C | |

SUC015 | 0.15±0.0005 | 1250mm | 300 g/sqm | 1200/1100N | -60-260°C | |

SUC018 | 0.18±0.01 | 1250mm | 380 g/sqm | 1800/1700N | -60-260°C | |

SUC018B | 0.18±0.01 | 1250mm | 380 g/sqm | 1800/1700N | -60-260°C | |

SUC025 | 0.23±0.02 | 3000mm | 500 g/sqm | 2100/1800N | -60-260°C | |

SUC025B | 0.25±0.02 | 3000mm | 500 g/sqm | 2100/1800N | -60-260°C | |

SUC030 | 0.30±0.02 | 3000mm | 560 g/sqm | 2800/2400N | -60-260°C | |

SUC030B | 0.30±0.02 | 3000mm | 560 g/sqm | 2800/2400N | -60-260°C | |

SUC035 | 0.35±0.02 | 3000mm | 640 g/sqm | 2600/2300N | -60-260°C | |

SUC035B | 0.35±0.02 | 3000mm | 640 g/sqm | 2600/2300N | -60-260°C | |

SUC040 | 0.40±0.02 | 3000mm | 720 g/sqm | 3000/2500N | -60-260°C | |

SUC040B | 0.40±0.02 | 3000mm | 720 g/sqm | 3000/2500N | -60-260°C | |

SUC055 | 0.55±0.02 | 3000mm | 840 g/sqm | 4400/4000N | -60-260°C | |

SUC065 | 0.65±0.02 | 3000mm | 1050 g/sqm | 5000/4800N | -60-260°C | |

SUC090 | 0.90±0.05 | 3000mm | 1550 g/sqm | 6000/5000N | -60-260°C | |

SUC090B | 0.90±0.05 | 3000mm | 1600 g/sqm | 6000/5000N | -60-260°C | |

PTFE Pure Film and Tape with Adhesive Data | ||||||

Item | Thickness | Width | Length | Peel Strength | Tensile Strength | Temperature |

mm | mm | m | N/100mm | N/100mm | °C | |

SUP008 | 0.08±0.01 | 500 | 10-50m | 23 | 900 | -60°C-260°C |

SUP013 | 0.13±0.01 | 500 | 10-50m | 24 | 1250 | -60°C-260°C |

SUP018 | 0.18±0.01 | 500 | 10-50m | 24 | 1650 | -60°C-260°C |

SUP025 | 0.25±0.01 | 500 | 10-50m | 24 | 2350 | -60°C-260°C |

Brown

Black

White

Beige

Smooth Surface

With Silicone Adhesive

With Release Paper

Food grade

Heat Press Machine

Heat Transfer machine

hot sealer machine

Insulation Jacket

About Company

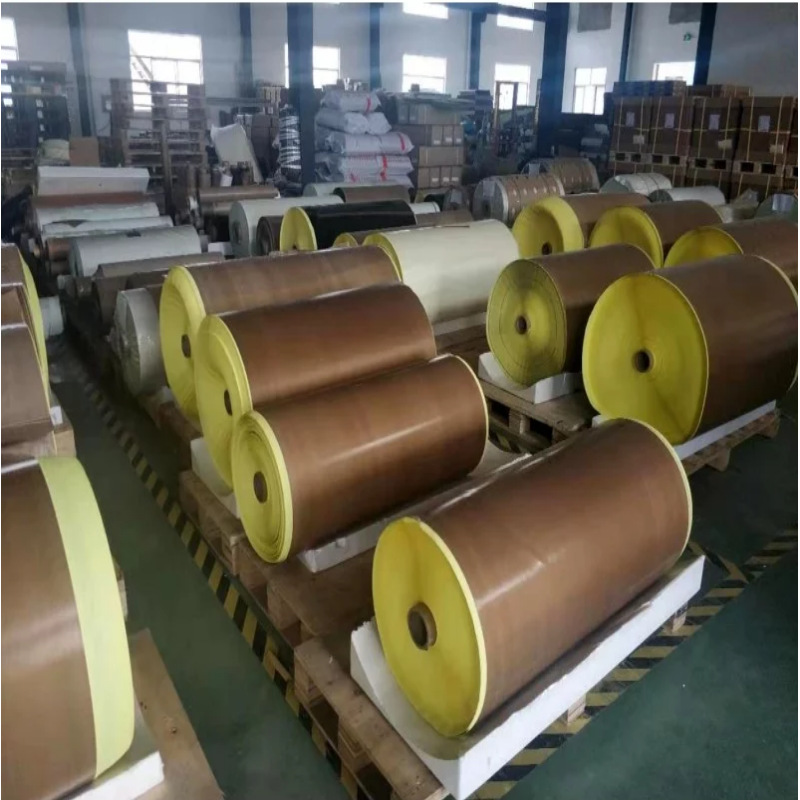

Professional PTFE teflon fiberglass fabric Manufacturer

Suconvey is a professional PEFT Teflon products manufacturer that chooses the highest quality raw materials from all over the world as our long time experience in this industry after comparing the materials from different countries and districts, we get rid of the materials with any bad feedback and products.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Mrs. Stephanie

- 86-13246961981

- [email protected]

Free Consultation

About Company

Professional PTFE Coated Glass Cloth with Release Paper Factory

One of the leading manufacturers of PTFE fabric film is SUCONVEY Manufacturing Company. With over 8 years of industry experience, SUCONVEY has established itself as a trusted supplier in the market. We specialize in producing high-quality PTFE fabric film that offers excellent heat resistance, chemical resistance, and non-stick properties. SUCONVEY prides itself on its advanced manufacturing processes and state-of-the-art facilities, ensuring consistent product quality and on-time delivery.

One notable feature of PTFE coated fiberglass fabric film is its excellent heat resistance. This material can withstand extreme temperatures ranging from -100°F to +550°F (-73°C to +287°C) without losing its integrity or functionality. This makes it an ideal choice for applications like heat sealing, packaging equipment, insulation pads, and conveyor belts in high-temperature environments.

PTFE Teflon Coated Sheet for Package for Sale

One of the key benefits of PTFE coated fiberglass fabric film is its exceptional heat resistance. This makes it an ideal material for use in environments where extreme heat is present, such as in the manufacturing of solar panels or heat sealing equipment.

Furthermore, PTFE coated fiberglass fabric film also possesses excellent non-stick properties. As a result, this material finds extensive application within the food industry for lining conveyor belts and baking sheets, preventing food from sticking and ensuring effortless release.

Additionally, due to its superior electrical insulation qualities and resistance to chemicals and moisture, PTFE coated fiberglass fabric film finds widespread use in electrical applications. It can be used as an insulating barrier in wire harnesses or as a protective wrapping for cables exposed to harsh environments.

Usage of PTFE Teflon Coated Fiberglass Film

- Heat Press Machine, Heat Transfer Machine, Heat Sealing Machine, Vacuum Sealing Machine

- Oven sheets, baking sheets, microwave gaskets and mold release materials

- PTFE coated fabric with a thickness of 0.45 mm or more can be used as a conveyor belt and thinner models can be used as belts for bonding and sealing machine

- As protective layer for equipment, such as for desulfurization unit in a power plant

- It can be used as wrapping materialin petroleum and chemical industries to resist corrosion or in electrica industries to insulate and resist high temperature

FAQ

Most frequent questions and answers

ask more question

The manufacturing process of PTFE coated fiberglass fabric film is a highly intricate and fascinating endeavor. To begin, the fiberglass fabric is carefully woven using durable and heat-resistant glass fibers. This fabric serves as the foundation for the film, providing strength and stability.

Once the fabric is woven, it undergoes a meticulous cleaning process to remove any impurities that may hinder adhesion later in the production process. Then comes the crucial step of applying a layer of liquid PTFE (polytetrafluoroethylene) coating onto both sides of the fabric. This coating ensures that the resulting film has remarkable non-stick properties, making it ideal for various applications.

As soon as the PTFE coating is applied, the fabric goes through multiple stages of drying and heating in order to solidify and bond with it completely. This sophisticated curing process not only enhances product durability but also ensures consistent quality throughout each batch produced.

- Please confirm your inquiry request as the usefulness.

- Please measure your application place size and count the quantity. If you have drawing, better send to us. If you have no drawing please tell me your application and tell me where do you want to use it, better to know the application equipment model, we can make drawing or solutions for you.

- We will making drawing as your demands or required products photos or pictures.

- Please confirm the size and quantity, especially the specifications of what you want so that I can supply the most precise guide and suggestions.

- Making samples as your exact requirements and appplications.

- Testing and confirm the samples and making upgrade if necessary.

- Placing order and prepare the production.

- Arrange the delivery after out of warehouse test.

- After-sale service follow the goods always.

Before purchase: Give the most professional guide for choosing the right products or service system.

After purchase: Any damage will be repair or replace new during warranty as long as use the products as the right way and normal wear of the products apart from any break by personal reasons.

After-sale: Always give the most professional suggestions for the products working status, give support for customers marketing developments of own brand business. Always repair as long as we keep cooperation.