Custom Silicone Rubber Tubes, Hoses & Pipes

Various of Silicone Tube&Hose Types

High Quality Silicone Tubing Manufacturer

USP Class VI: Biocompatible platinum-cured tubing for life sciences and surgical equipment.

Fat-resistant and ultra-flexible tubing designed for the rigorous cleaning cycles of the dairy industry.

Used in medical devices where X-ray visibility is required for accurate placement and monitoring.

Cold shrink tubing is a type of tubing that is pre-expanded at the factory and fitted onto a removable support spiral core.

High-performance heat shrink tubing with controlled shrink ratios, consistent wall integrity and electrical insulation.

Combines two materials (e.g., solid silicone with Silicone foam) for chemical and heat resistance.

Used for thermal insulation of mechanical pipe walls, made of high-temperature resistant silicone materials.

Conduct electricity due to the fact that it is made with a conductive material, such as carbon black.

Multi-layer construction with polyester or fiberglass braiding for extreme pressure resistance.

Multi-layer reinforced hoses designed for automotive heat and oil resistance.

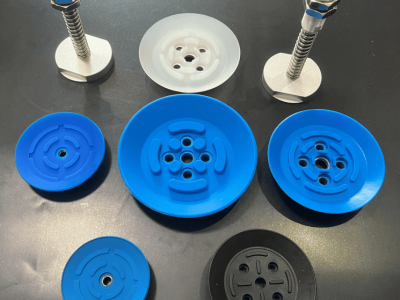

Suconvey manufacture high quality straight and bending reducers in various sizes.

Custom ID/OD, colors, and specific Shore A hardness based on your CAD drawings.

Technical Datasheet

Item | Data | Item | Data |

Thickness | 0.1mm~30mm | Diameter | 0.3mm~150mm |

Length | Endless | Specific Gravity | 0.2g/cm3~1.3g/cm3 |

Shape | T/D/P or design | Material | Solid Silicone,Sponge silicone |

Function | Dust/water proof, noise/ shock reduction | Resistant | Oil, chemical, heat |

Color | Pantone Card and transparent | Hardness | 20~90 Shore A |

Appearance | Smooth/Wave/Braided | Temperature | -60℃-350℃ |

Tear Strength | Up to 12 Mpa | Elongation | 300-650% |

Deformation Rate | ≤9% | Anti-Flammable | UL 94 – V0 |

Acid and Alkali Resistance | Available | Insert Layer | Fabric or Canvas |

Chemical Safe | ROHS | Food Grade | FDA Approved |

Medicine | Passed Halogen Test | Water Absorption | 20% for silicone, 80% for sponge |

High Quality Silicone Rubber Hoses Supplier

- Laser-Controlled Extrusion: We utilize real-time laser diameter gauges on all extrusion lines to maintain a wall thickness tolerance of 0.1mm. This ensures a perfect fit for connectors and consistent flow rates.

- Zero-Contamination Environment: Our medical and food-grade tubing is produced in a controlled environment to prevent airborne particulates from compromising material purity.

- High-Speed Production: With 6+ automated extrusion lines running 24/7, we have a daily capacity of 15,000+ meters, ensuring we can meet large-scale OEM demands without lead-time delays.

Global Compliance & Certifications

Our facility is not just a workshop; it is a globally compliant partner. We strictly adhere to:

- FDA 21 CFR 177.2600: For food and beverage contact.

- USP Class III: For medical-grade biocompatibility.

- UL-94 V0: For self-extinguishing flame retardancy in EV and rail applications.

- RoHS & REACH: Ensuring 100% heavy-metal-free and eco-friendly materials.

Rigorous Quality Assurance

We don’t guess; we test. Every batch comes with a Certificate of Analysis (COA) including:

- Burst Pressure Testing: We verify the maximum pressure limits for our braided and high-pressure hoses using hydraulic test benches.

- Compression Set & Tensile Tests: Ensuring the tube returns to its original shape after repeated use in peristaltic pumps.

- Accelerated Aging: We simulate 1+ years of UV and heat exposure to guarantee the longevity of our industrial pipes.

Reliable Silicone Rubber Tubing Supplier in China

Rapid Prototyping: Get custom-sized samples in 5–7 business days to accelerate your R&D cycle.

Custom Printing(OEM): High-durability inkjet marking for part numbers, safety specs, or your own brand logo directly on the hose.

Precision Cutting & Assembly: We offer automated length cutting (no frayed edges) and can pre-install stainless steel couplings or clamps.

SUCONVEY Service

With over 11 years of experience in the rubber industry, we possess a wealth of expertise. SUCONVEY is dedicated to solving the rubber challenges faced by industries worldwide.

Frequently Asked Questions

If your question is not listed, please contact us.

Platinum-cured tubing is non-yellowing, peroxide-free, and has a smoother internal surface, which is critical for food and medical applications to prevent bacterial buildup.

Standard thin-walled silicone tubing may collapse under high vacuum. For vacuum applications, we recommend our High-Pressure Reinforced Hoses or Heavy-Wall Silicone Pipes. These are engineered with increased wall thickness or wire-reinforced structures to maintain their shape and prevent kinking or collapsing under negative pressure.

Shore A hardness (typically ranging from 30A to 80A) determines the tube’s flexibility and “squeeze” recovery. For example, 50A to 60A is the standard for peristaltic pumps because it offers the perfect balance of flexibility and rebound. 70A to 80A is better for high-pressure industrial hoses that require more structural rigidity and resistance to bursting.

Yes. We can match any Pantone or RAL color to align with your brand or to color-code different fluid lines in a factory setting. Additionally, we provide inkjet branding directly on the tubing, allowing you to include your company logo, part numbers, safety ratings, or measurement markers (e.g., meter marks) for easier installation.