What are silicone rubber and viton?

Silicone rubber and viton are two materials that are often used in manufacturing and engineering. They have both benefits and drawbacks, which should be considered when deciding which one to use for a specific purpose.

Silicone rubber and viton are two different types of elastomer, or synthetic rubber. Both materials are commonly used in applications where flexibility, durability, and resistance to heat and chemicals are required. However, there are some important differences between the two materials that should be considered when selecting a material for a particular application.

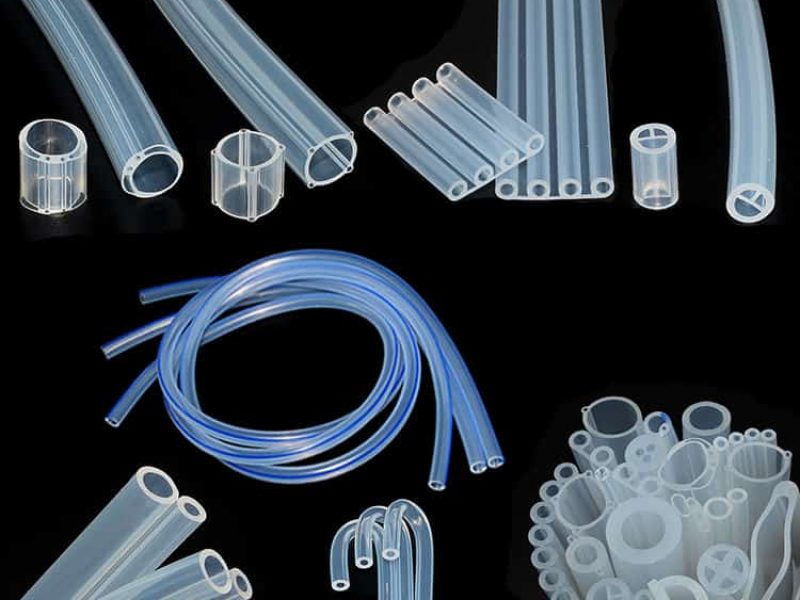

Silicone rubber is a synthetic polymer made up of silicon and oxygen atoms. Silicone rubber has a wide range of applications due to its unique combination of properties. It is resistant to extreme temperatures, both hot and cold, making it an ideal material for use in applications where temperature extremes are a factor. Silicone rubber also has excellent electrical insulation properties and is resistant to UV light and ozone, making it suitable for use in outdoor applications. However, silicone rubber does not have the same level of resistance to petroleum-based fluids as viton does.

Viton is a synthetic rubber made from fluoroelastomer, which is a copolymer of vinylidene fluoride and hexafluoropropylene. Vinylidene fluoride is a powerful fluorinating agent, which gives viton its excellent resistance to oils, fuels, and other petroleum-based fluids. Viton is also resistant to high temperatures, making it an ideal material for use in gaskets and seals in engines and other high-temperature environments. Viton does not break down as easily as silicone rubber when exposed to high temperatures. However, viton does not have the same level of resistance to UV light and ozone as silicone rubber does.

What are the differences between silicone rubber and viton?

Silicone rubber and Viton have a few key differences that set them apart. For one, silicone rubber has a lower heat resistance than Viton, making it ideal for applications that don’t require as much heat resistance. Additionally, silicone rubber is generally more flexible than Viton, making it better suited for applications where flexibility is important. Finally, silicone rubber typically costs less than Viton, making it a more economical choice for many applications.

Viton® is a high performance synthetic rubber used extensively in O-rings, fuel system and emission control applications. Viton® is also well suited for many industrial and automotive wiring hoses where resistance to fuels, oils, lubricants and aggressive chemicals is required.

Silicone rubber is an elastomer composed of silicone—itself a polymer—containing silicon together with oxygen, carbon, hydrogen, and sometimes other chemical elements. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve specific properties.

What are the benefits of silicone rubber?

Silicone rubber has a number of advantages over other types of rubber. It is resistant to extreme temperatures, both hot and cold, and it remains flexible over a wide range of temperatures. It is also resistant to aging, UV light, ozone, and oxygen. Silicone rubber does not break down easily, so it has a long lifespan.

What are the benefits of viton?

Viton is a synthetic rubber that is used in a variety of applications requiring resistance to high temperatures, chemicals, and oils. It has excellent resistance to heat, chemicals, and oils, making it ideal for sealing applications. Viton is also more resistant to cold temperatures than other rubbers, making it ideal for applications in extreme environments.

How do silicone rubber and viton compare in terms of cost?

There is a significant difference in the cost of silicone rubber and viton. Silicone rubber is much less expensive than viton. The difference in cost is due to the difference in production costs. Viton is made from synthetic materials, while silicone rubber is made from natural materials.

How do silicone rubber and viton compare in terms of durability?

Silicone rubber and viton are both very durable materials. However, viton is significantly more durable than silicone rubber. Viton can withstand higher temperatures and is more resistant to chemicals, while silicone rubber is more flexible and has a lower density.

How do silicone rubber and viton compare in terms of resistance to chemicals?

While both silicone rubber and viton are resistant to many chemicals, there are some key differences between the two. Viton is generally more resistant to oils and fuels, while silicone rubber is more resistant to water and heat. In terms of specific chemicals, viton is better able to resist acetic acid, acetone, and mineral oil, while silicone rubber is better able to resist benzene, Freon, and peroxide.

How do silicone rubber and viton compare in terms of resistance to heat?

Silicone rubber can withstand temperatures up to 180°C (356°F), while viton can withstand temperatures up to 200°C (392°F). In terms of resistance to heat, viton is better suited for applications that require extended exposure to high temperatures.