What are silicone rubber and polyurethane?

Silicone rubber and polyurethane are two widely used elastomers. They are both durable materials that can be used for a variety of applications, but there are some key differences between them.

Silicone rubber is a synthetic rubber made from silicone, a compound of silicon and oxygen, meaning it has the ability to return to its original shape after being stretched or compressed. Silicone rubber has many useful properties, including high heat resistance, low toxicity, and resistance to weathering and aging. It is used in a variety of applications, including seals, gaskets, electrical insulation, and automotive parts.

Polyurethane is another synthetic rubber made from polyurethane, a compound of carbon, hydrogen, and oxygen, but it is not as flexible as silicone rubber. Polyurethane also has many useful properties, including high abrasion resistance and flexibility. It is used in a variety of applications such as flexible foam cushions, coatings, adhesives, and sealants.

What are the key differences between silicone rubber and polyurethane?

When it comes to choosing a material for your product, it is important to consider the characteristics of each option. This is especially true when deciding between silicone rubber and polyurethane. Though both materials are excellent choices for many products, they have different characteristics that may make one more suitable than the other.

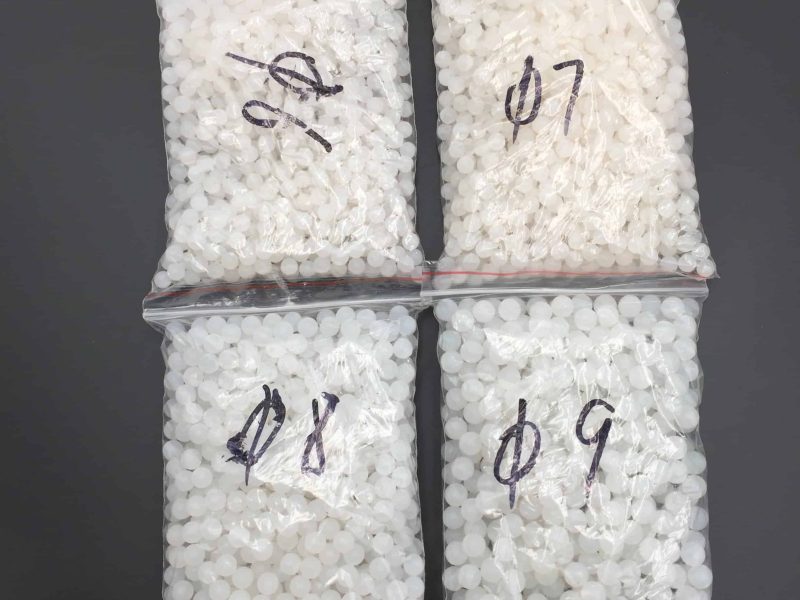

One key difference between silicone rubber and polyurethane is durometer, or hardness. Silicone rubber has a wide range of hardness, from very soft to very hard. This makes it ideal for products that need to be soft or flexible, such as gaskets or seals. Polyurethane also has a wide range of hardness, but its hardest options are harder than silicone rubber’s hardest options. This makes polyurethane better suited for products that need to be firm, such as wheels or casters.

Another difference between silicone rubber and polyurethane is the curing process. Silicone rubbers are cured by different methods, including heat, room temperature vulcanization, and radiation. Polyurethane has a more limited range of curing processes.

Last, Silicone rubber is generally more heat resistant and durable than polyurethane, but it is also more expensive. Polyurethane, on the other hand, is more flexible and has a lower density, making it lighter in weight.

What are the benefits of silicone rubber?

Silicone rubber has a variety of benefits that make it ideal for use in many different industries and applications. One of the most notable benefits of silicone rubber is its resistance to extreme temperatures. This means that it can be used in high-temperature environments without fear of damage or degradation. Additionally, silicone rubber is also highly resistant to chemicals, making it an ideal material for use in situations where there is potential for exposure to harsh chemicals.

What are the benefits of polyurethane?

Polyurethane is a strong, durable material that can be used for a variety of applications. It is resistant to tearing and abrasion, making it an ideal choice for high-wear items such as car parts, gears, and rollers. Polyurethane is also waterproof and resistant to chemical attack, making it ideal for outdoor use.

Environmental impact: how do they affect the environment?

Though both polyurethane and silicone rubber are synthetic materials created through polymerization, they have different properties that make them each more suitable for specific applications. The main difference between the two is that polyurethane is a thermoset while silicone rubber is a thermoplastic. This means that once polyurethane cures, it cannot be melted and reformed like silicone rubber can. Another key difference is that polyurethane contains carbon while silicone rubber does not.

When it comes to environmental impact, both materials have pros and cons. On the plus side, neither contains toxic chemicals or heavy metals so they can be safely disposed of without harming the environment. However, because they are both synthetic materials made from petroleum-based products, they are not biodegradable and will remain in landfills for many years.

When is silicone rubber the best choice?

There are many types of rubber, and each has unique properties that make it better suited for certain applications. Silicone rubber is one of the most versatile types of rubber, and it has a wide range of applications. Here are some situations when silicone rubber is the best choice:

-When you need a rubber that can withstand extreme temperatures: Silicone rubber can withstand temperatures from -55°C to +300°C, making it ideal for applications where other rubbers would fail.

-When you need a rubber that is resistant to chemicals: Silicone rubber is resistant to many different chemicals, including oils, greases, and acids. This makes it an ideal choice for applications where other rubbers would be damaged.

-When you need a rubber that has good electrical insulation properties: Silicone rubber is an excellent insulator and can be used in applications where electrical components need to be isolated from each other.

-When you need a flexible rubber: Silicone rubber is much more flexible than other types of rubbers, making it ideal for applications where flexibility is required.

When is polyurethane the best choice?

Polyurethane rubber is a versatile material that can be used in a variety of applications. It has excellent abrasion resistance, making it ideal for products that will see heavy use. It also has good chemical resistance, making it a good choice for products that will come into contact with hazardous materials. Polyurethane is also a good insulator, making it ideal for products that need to protect against electrical hazards.

How to choose between silicone rubber and polyurethane?

This is a common question with no easy answer. It depends on the application and the specific properties required. Here are some general guidelines:

If high temperature resistance is required, go with silicone rubber. It can withstand temperatures up to 204°C (400°F). Polyurethane can tolerate temperatures up to 93°C (200°F). Such as heat transfer silicone rubber rollers.

If low temperature flexibility is necessary, choose silicone rubber. It stays flexible down to -55°C (-67°F). Polyurethane becomes hard and brittle at -40°C (-40°F).

If chemical resistance is a must, again, pick silicone rubber. It holds up well in oils,grease, gasoline, and hydraulic fluids. Polyurethane has poor resistance to oils and greases but does well with aliphatic hydrocarbons such as gasoline.

Polyurethane outperforms silicone rubber in abrasion resistance, tear strength, and tensile strength. If these properties are important, go with polyurethane. Such as: Anti-slip mat for drilling platform, PU vibrating screen.

Conclusion

From the above discussion, it is clear that silicone rubber has many advantages over polyurethane. Silicone rubber is more flexible, durable, and can withstand higher temperatures than polyurethane. It also has a wide variety of uses and can be customized to meet specific needs. However, silicone rubber is more expensive than polyurethane and is not as easy to obtain.