What is Silicone?

Silicone is most commonly used as a sealant, because of its ability to form a durable, waterproof bond. It is also heat-resistant and non-reactive with many substances, making it ideal for sealing in food products like jams or jellies. Silicone can also be used for insulation, due to its low thermal conductivity and resistance to extreme temperatures. This makes it an effective choice for gaskets in machinery and electrical components. Additionally, silicone can be found in medical devices such as catheters and IV lines due to its hypoallergenic nature and flexibility. Finally, silicone can be formulated into rubber or silicones elastomers which are known for their strength, durability and abrasion resistance; they are often seen in parts of vehicles like the door seals or window seals.

Uses in Food Preparation

Silicone is most commonly used in the kitchen for food preparation. This material is ideal for use with both hot and cold foods, as it can withstand temperatures up to 446°F (230°C). It is also non-toxic and doesn’t react with food or beverages, making it a safe choice for cooking utensils. Silicone is often used to make baking pans, muffin trays, spatulas and other cooking tools. Its non-stick properties mean that less oil or butter needs to be used when cooking, making dishes healthier overall. It can also be reused many times before needing to be replaced due to its sturdy nature. In addition, silicone’s flexibility makes it easy to store away when not in use, taking up minimal space on kitchen shelves or cupboards.

Uses in the Kitchen

Silicone products are widely used in the kitchen due to their versatility and able to withstand heat. It is commonly found in bakeware and cookware, such as spatulas, measuring cups, muffin trays and oven mitts. Silicone is non-toxic, meaning it does not leach chemicals into food or beverages when heated. It also does not contain any petroleum-based products which can sometimes be found in other materials like plastic. Furthermore, silicone is easy to clean as most of its components are dishwasher safe. Its flexibility allows for more intricate details that can’t be achieved with metal or plastic cookware so it’s often used for more sophisticated tasks such as baking cakes with intricate designs or making homemade chocolates. With this said, silicone is the perfect material for anyone who loves baking and cooking!

Uses in the Bathroom

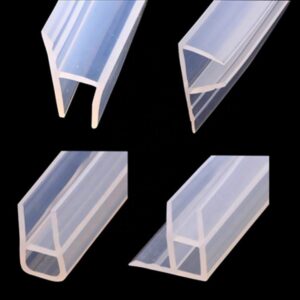

Silicone is a versatile material that can be used in many different ways in the bathroom. Some of the most common uses for silicone in bathrooms include sealing around bathtubs, showers, and sinks; creating waterproof barriers between tiles and walls; and making caulk to fill gaps between tiles.

Silicone can also be used as a sealant for plumbing fixtures such as taps, showers, and toilets. It provides an effective barrier against water seepage and leaks, ensuring that water does not get into places where it shouldn’t go. Silicone is also often used to create waterproof seals between glass shower doors or panels, which helps prevent them from becoming foggy or damaged by moisture.

Finally, silicone can be applied to surfaces such as counters and floors in order to create a non-slip surface. This makes them safer for use when wet or damp conditions exist in the bathroom. It also helps prevent slips on ceramic tiles which can become quite slippery when wet.

Uses in the Garden

Silicone is widely used in gardens for a variety of purposes. It can be used to waterproof garden furniture, helping them to withstand the elements and remain sturdy for years. Silicone sealants are also commonly used to secure joints between different materials such as wood and metal, ensuring that the structures remain stable and secure. In addition, silicone can be applied around pipes and drains to ensure there are no water leaks. As well as this, silicone can also be sprayed onto plants or flowers to create a protective barrier against pests or disease. This helps them stay healthy and increase yields from crops. Finally, liquid silicone can also be used to fill cracks in walls or paths within the garden, preventing further damage from weathering or wear-and-tear over time.

Industrial Applications

Industrial applications of silicone are numerous and varied. One of the most common uses for silicone is as a sealant. Silicone sealants can be used to waterproof, fill gaps and create airtight seals in construction projects, automobiles, plumbing fixtures and other industrial applications. Silicone sealants offer superior adhesion and flexibility compared to traditional materials such as epoxies or urethanes, making them extremely useful in many different industries.

Silicone also has excellent heat resistance properties that make it ideal for use in high-temperature environments like automotive engines, ovens or dryers. For this reason it is often used to manufacture components like gaskets, O-rings and other rubber parts which must withstand extreme temperatures while still maintaining their structural integrity. Silicone can also be used as an insulator in electrical systems due to its low thermal conductivity properties.

In addition to these uses, silicone is often used as a coating for surfaces which require protection from corrosion or abrasion due to its unique chemical composition that resists water, oil and most acids and bases. This makes it ideal for use on machinery parts exposed to harsh chemicals or outdoor elements where regular maintenance would otherwise be required.

Common Uses in Cosmetics

Silicone is commonly used for cosmetic purposes due to its non-toxic and non-irritant properties. It helps to create a smooth texture in creams, lotions, and foundations that make them easy to apply and adhere better on the skin. Silicone also helps keep makeup looking fresh longer by creating a barrier between the skin and the environment. This can help reduce sweat, oil, and other environmental factors from affecting foundation or concealer coverage. In addition, it has been proven to provide an improved appearance of fine lines and wrinkles on the face as well as helping with moisture retention in dry skin areas.

Role in Electronics & Telecommunications

Silicone is a versatile material that has a wide range of uses in electronics and telecommunications. It is most commonly used as an insulation material that provides protection from heat, cold, moisture, radiation, and other elements. It also has excellent electrical properties and can be used to insulate electrical components such as wires and cables. Silicone can also be used in the manufacture of circuit boards where it acts as an adhesive between components and helps to keep them in place mechanically. Additionally, silicone is resistant to corrosion which makes it ideal for use in communications systems such as cell phones or radios where contact with water or other liquids could cause damage. Finally, silicone can be used to make waterproof seals on electronic equipment which keeps electricity safely contained while protecting the device from external elements.

Use in Automotive Industry

Silicone has become one of the most commonly used materials in the automotive industry due to its flexibility, durability and heat resistance. It is used in a variety of products, from window sealant to rubber gaskets and spark plug boots. Automotive manufacturers use silicone because it can be molded into complex shapes and withstand extreme temperatures without degrading or corroding. Silicone is also used for coating cars to provide a protective barrier against water, dirt, salt and other damaging elements that could potentially damage the car’s paint. Additionally, silicone is often used in engine hoses because it can easily slip over metal piping without binding or cracking. This makes it an ideal choice for automotive applications where tight spaces are necessary and long-term reliability are key requirements.

Marine/Aquatic Use

Silicone is most commonly used in marine aquatic applications. It is widely used to create seals and gaskets for boats, and for waterproofing around windows and hatches. Silicone can also be used on boat hulls to protect them from the elements and provide an extra layer of protection. Silicone coatings are available in a variety of colors, so they can be used to customize the look of a boat or other watercraft. In addition, silicone is often used as lubricant on boat propellers, shafts, and other components that come into contact with water. It helps reduce friction while sailing, making it easier to maneuver the vessel at high speeds. Lastly, silicone can also be found in products such as fish tanks or aquariums where it helps create a safe environment for marine creatures to live in by creating an impenetrable seal against leakage or contamination.

Uses in Medicine

Silicone is most commonly used in the medical field. It is used to make prosthetic devices such as artificial limbs, orthotic braces, and dental implants. As a result, these medical prostheses are highly durable, resistant to bacteria growth, and can be very comfortable for the user. Silicone’s flexible and non-porous nature also makes it ideal for creating catheters and other tubes used in surgical procedures. Additionally, silicone is often employed to construct seals or gaskets around delicate medical instruments or equipment such as pacemakers and defibrillators. This helps keep them waterproof while still allowing access for maintenance or repairs. As a result of its biocompatibility with human tissue and low toxicity levels, silicone has been increasingly used for wound dressing applications in recent years. Finally, silicone oil has been found to be useful in ophthalmic surgeries due to its ability to reduce inflammation caused by dry eyes.

The most common use of silicone is for medical purposes. It is used in a variety of medical products such as implants, catheters, prosthetics, joint replacements and dental materials. Silicone is often chosen because of its durability and ability to resist heat and corrosion. Additionally, it can be produced in soft forms that are safe for use with human tissues and organs. In recent years, silicone has become increasingly popular because it offers superior biocompatibility compared to other materials used in medical settings. Silicone-based products are also considered to be more cost effective than many alternative options due to their high performance at a lower cost. Furthermore, the material can easily be sterilized which makes it safe for use with patients with compromised immune systems or allergies to certain materials.

Construction and Home Repair

Silicone is one of the most versatile materials used in construction and home repair. It’s a popular choice for sealing, waterproofing, adhering, and protecting surfaces from moisture and other environmental factors. Its main use is as a sealant for windows, doors, vents, pipes, fixtures and more. It can also be used to fill cracks or gaps in walls or floors. In addition to sealing applications, silicone is often used as an adhesive to attach various materials like tile backer boards or insulation panels to walls or floors. Its flexibility makes it ideal for use in areas with continuous movement such as foundations and roofs where traditional caulking compounds are unable to provide sufficient protection against moisture damage. Finally, it can also be used as an alternative to caulk when creating a weatherproof seal around window frames and door frames.

Use for Waterproofing

Silicone is most commonly used as a waterproofing agent. It can be applied to various materials, ranging from metal and plastic to fabric, wood and concrete. Silicone is an effective way to seal leaks and prevent water damage. It forms a durable coating that repels moisture, reducing the risk of rot or mold growth within the material it’s applied to. Additionally, silicone is resistant to most chemicals and temperature changes which makes it perfect for sealing around bathtubs, showers, sinks, windowsills and other areas subject to humidity or frequent wetting. Another important use of silicone in waterproofing applications involves creating a sealant between two different materials such as ceramic tile and bathroom fixtures—it prevents water from penetrating into cracks or crevices between them while also providing flexibility so they’re able to withstand thermal expansion without cracking or separating over time.

Uses in Everyday Life

Silicone is one of the most versatile materials found in everyday life, with a wide range of applications. The most common use of silicone is in sealants and adhesives. Silicone sealants are used for a variety of purposes such as waterproofing, sealing cracks around windows and doors, or filling gaps between tiles. They have the unique ability to withstand extreme temperatures and maintain flexibility when cured, making them great for both indoor and outdoor uses.

Silicone also has many medical applications due to its biocompatibility, which means it can be safely used on humans without causing any harm. This makes it perfect for medical devices such as catheters, implants, prosthetics, wound dressings and surgical tools; all designed to stay put even under water or heat exposure. Additionally silicone is often found in contact lenses due to its non-irritating properties that make it comfortable to wear all day long.

Finally silicone is also widely used in consumer products like cooking utensils and bakeware since it can resist high temperatures without melting or releasing toxic fumes into food items. It’s also frequently used as an insulating material for electrical equipment such as wires and cables due to its shock resistance capabilities which help protect these items from damage caused by voltage spikes.

Other Applications

Silicone is used in a variety of applications outside of its most popular use, which is consumer products. In industrial settings, silicone rubbers are used to create seals and gaskets due to their ability to resist temperatures up to 315°C (599°F). They are also resistant to extreme temperatures, weathering, ozone, UV radiation, and many chemicals. Because they can be formulated with a wide range of properties they offer design flexibility for engineers looking for solutions that can withstand harsh environmental conditions.

In addition to industrial applications, silicone rubber is widely used in medical device tubes. It has a number of advantages for medical purposes as it does not stretch or tear when exposed to continuous movement and stress like other rubbers may do over time. Silicone rubber parts are also biocompatible and non-irritating which makes them ideal for use around sensitive areas like the ears or eyes. Furthermore, silicone rubber parts can be cleaned easily and sterilized with common methods like steam autoclaving or Ethylene Oxide gas sterilization which helps reduce the risk of infection from contaminated instruments being reused.

Recreational Uses

Silicone is an incredibly versatile material, and its most common use might be as a sealant or adhesive in home improvements or repairs. Its non-toxic properties make it a popular choice when working with food and drink items, such as baking molds and reusable water bottles. However, silicone can also provide many enjoyable recreational uses.

Silicone can come in a variety of fun shapes and colors for crafting projects. It can be used to make custom jewelry pieces, like necklaces and earrings; keychains, lanyards, and other items that require durable elasticity; stretchable rubber bands for tying up cords or organizing small objects; colorful bracelets for medical alert systems; and even toys for children. Additionally, silicone is great at retaining heat or cold temperatures which makes it perfect for creating hot/cold packs to help relax muscles after physical activities or reduce swelling after injuries.

These days silicone products have become so popular that they are now being used as a decorative element in the home – furniture pieces have been designed to incorporate silicone into their structure either partly or completely – adding texture, shape and color. There are also plenty of creative ways to use them outdoors – by creating outdoor sculptures using liquid silicones that harden into place once cured – making them long lasting additions to any garden!

Benefits of Using Silicone

The most common use of silicone is as a sealant and adhesive. It has many beneficial properties such as flexibility, heat resistance, water resistance, and chemical stability. These qualities make it a great choice for sealing cracks and crevices in areas exposed to extreme temperatures or moisture. Additionally, silicone is highly resistant to corrosion from many acids, bases, and salts which makes it an ideal choice for outdoor applications.

Silicone also provides excellent insulation properties that can be used to protect electrical components from damage caused by high temperatures or humidity levels. This makes it perfect for creating weather-proof seals around windows and doors in order to prevent air infiltration. Furthermore, silicone’s non-toxicity ensures that it won’t cause any harm if accidentally ingested by humans or animals. Its non-flammability property also means that it will not ignite easily when exposed to flames or sparks which further increases its safety factor. Finally, due to its durability and long lifespan, using silicone sealants can save money over time since they rarely need replacing compared to other types of sealants.

Alternatives to Silicone

Silicone is a synthetic rubber polymer used for a variety of purposes. It’s most commonly used as an adhesive and sealant in construction, automotive, and other industries. Silicone’s pliability, durability, and resistance to extreme temperatures makes it ideal for these applications. However, there are some alternatives to silicone that can be used in many of the same areas.

One such alternative is polyurethane (PU). PU is also a synthetic rubber polymer but has different properties than silicone. PU adhesives offer good abrasion resistance and flexibility while being able to bond with multiple surfaces including wood, metal, plastics, ceramics and glass. Unlike silicone which remains permanently flexible at room temperature, PU undergoes plastic deformation when exposed to heat or pressure so it should not be used in high-temperature applications.

Another option is butyl rubber tape which is made from a blend of butyl rubber and PVC resin compounds with added tackifiers like rosin or bitumen resins. Butyl tape offers excellent adhesion on many materials including metals and plastics as well as providing superior environmental protection against water ingress or ozone exposure with its tight seal around pipes or cables joints where needed.

Conclusion: Popular Uses of Silicone

Silicone is most commonly used as a sealant, adhesive, or lubricant. It is also used in cookware and bakeware due to its high heat resistance. Silicone can also be found in certain medical applications such as implants and prosthetics; it is ideal for these because it does not react with body fluids or tissues. Additionally, silicone rubber is widely used in the automotive industry to make gaskets, hoses, and other components that need to withstand extreme temperatures. Finally, silicone is becoming increasingly popular for construction purposes due to its strength and flexibility; builders use it as an effective waterproofing material for roofs, walls and foundations.