Rubber products for Machinery

Learn about the variety of rubber products for machinery that SUCONVEY services.

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

SUCONVEY Service

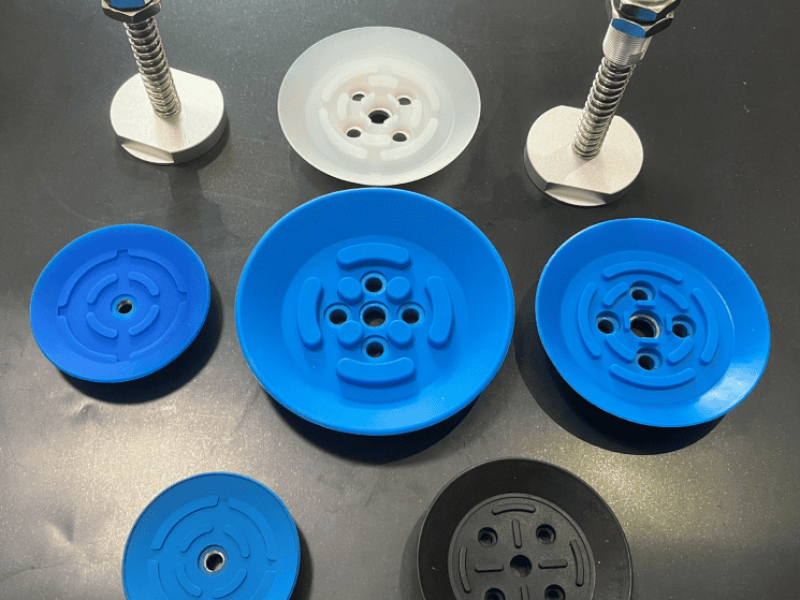

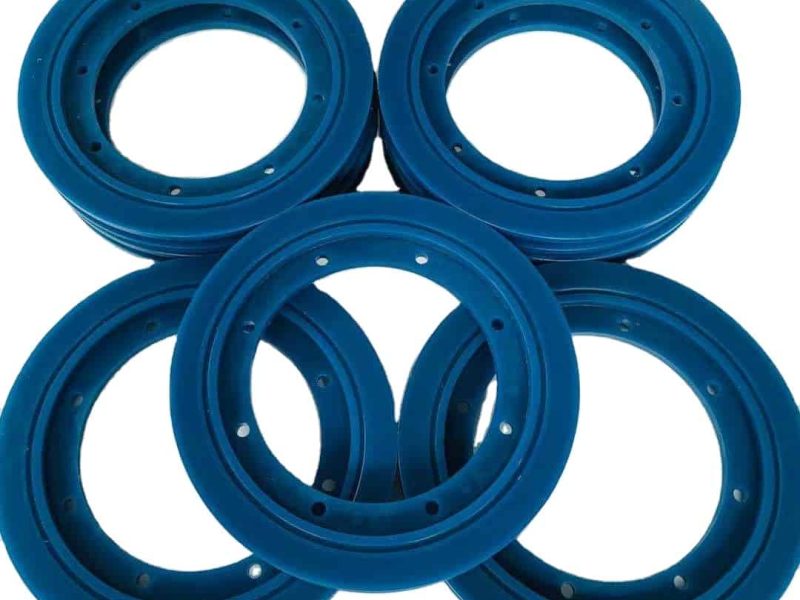

We specialize in rubber products for the mechanical industry, including sealing systems, shock absorption and damping, transmission and conveying, fluid transfer, and protection and dust prevention.

SUCONVEY - Rubber Products Manufacturer in the mechanical industry

Suconvey is more than just a manufacturer. we are your partner committed to excellence with rubber products for machinery services. As a rubber product manufacturer, understanding the needs of the machinery industry is crucial. Rubber plays an indispensable role in mechanical engineering due to its unique elasticity, abrasion resistance, corrosion resistance, and electrical insulation properties.

Expertise and Experience

We have served various sub-sectors including construction machinery, CNC machine tools, and automation equipment, accumulating a vast library of formulas and mold databases, enabling us to quickly provide mature solutions.

High quality raw materials

SUCONVEY has an independent laboratory that can conduct modification research and development for different needs (such as oil resistance, acid and alkali resistance, ozone resistance), ensuring that the product performance is superior to general standards at the molecular level.

Product Certificate

We have ISO 9001: 2015 Environmental Management Certificate, FDA, UL or industry-specific antistatic/Flame Resistance Certificate, ROHS Certificate and eight product patents according to customer needs.

Customized services

We provide full-process technical consulting, from drawing design, material selection, mold development to prototype manufacturing. Whether it’s high-precision, small-batch customization of special parts or large-scale standardized production, it can all be achieved efficiently through precision molding or extrusion processes.

Quality Assurance

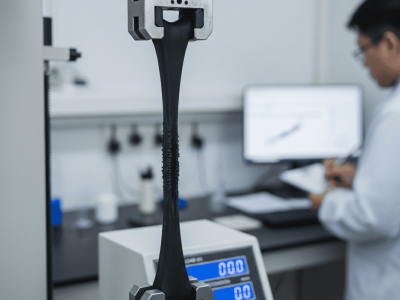

We implement closed-loop management from incoming quality control (IQC), process quality control (IPQC) to finished product quality control (FQC) to ensure the ultimate stability of product dimensional accuracy tolerances and physical properties. It possesses advanced tensile testing machines, aging test chambers, ozone detectors, and high-precision image measuring instruments (2D).

Comprehensive after-sales service

In case of installation or usage problems, technical engineers can respond within 12 hours, providing on-site troubleshooting and improvement suggestions. Establish customer files and conduct regular follow-ups on product operation. Based on the needs of machinery and equipment upgrades, assist customers in product iteration development and cost reduction.

More Than Just a Rubber Products Manufacturer

Customer Support

SUCONVEY customer specialists are devoted to providing flexible rubber products for machinery solutions for clients worldwide. Always keep you posted about the latest trend and technology. And we’re happy to give you a heads up for price changes!

Delivery Service

Our logistics teams are dedicated to providing expert service for all regions. We strive to maintain long-term relationships with shipping lines and agents.

Frequently Asked Questions

If your question is not listed, please contact us.

How do I choose the most suitable rubber material based on my machine’s operating environment? A: Material selection mainly depends on three factors: the working medium (e.g., oil, water, chemicals), the operating temperature (maximum/minimum temperature), and the stress state (dynamic seal, static seal, or load-bearing). We will recommend the most cost-effective material based on the operating parameters you provide (e.g., polyurethane for wear resistance, rubber for weather resistance, and Silicone for high temperature resistance).

Yes. We have enhanced formulas specifically developed for high-pressure hydraulic systems, combined with special structural designs (such as adding a skeleton or fiber layer) to ensure that our products maintain excellent fatigue resistance and dimensional stability under high-frequency dynamic environments.

The process typically includes: requirements communication → technical assessment (materials/structure) → mold design and development → prototype production → performance testing → customer confirmation → mass production. We can develop based on your drawings, physical samples, or even a design concept.

It depends on the complexity. Mold development for standard seals or simple gaskets usually takes 7-10 business days; molds for more complex injection molding or irregularly shaped parts typically take 15-25 business days. For urgent projects, we can provide expedited prototyping services.

We implement strict batch management. From the initial raw material mixing, each batch of rubber compound undergoes rheological property testing; during the production process, automated equipment is used to control vulcanization pressure, temperature, and time; before leaving the factory, finished products undergo sampling or full inspection by precision testing equipment to ensure that the hardness, dimensions, and tensile properties of each batch of products are consistent.

Yes. All our raw materials and additives undergo rigorous screening and fully comply with international standards such as EU RoHS 2.0, REACH, and FDA (if food processing machinery is involved), and we can provide corresponding third-party testing reports with the shipment.

We maintain a high degree of flexibility with our customers in the machinery industry. For standard parts, we have a standing inventory with no minimum order quantity; for custom parts, due to the involvement of machine setup and mold amortization, we will negotiate a reasonable starting quantity with you based on the specific part’s size and manufacturing process.