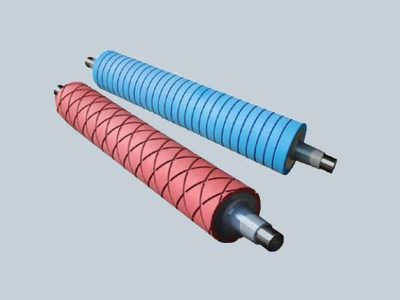

Custom Silicone Rubber Roller Manufacturer & Supplier

Various of Roller Types

High Quality Silicone Coated Rubber Rollers

Our heat resistant rollers for hot stamping offer superior thermal conductivity and high-temperature stability. They ensure a perfect, uniform transfer of decorative foils to various substrates.

Best for: Plastic decorating, wood grain transfer, and automotive trim.

Specifically engineered for the food and beverage industry. These rollers feature non-toxic, FDA-compliant materials that ensure safety and hygiene while maintaining excellent release properties.

Best for: Food packaging, chocolate processing, and pharmaceutical lines.

Designed with a specialized coated surface, these rollers ensure a consistent and even spread of adhesives. The non-stick nature of our silicone makes cleaning quick and easy, reducing downtime.

Best for: Woodworking, labeling, and adhesive coating industries.

Precision-ground rollers designed for the laminating industry. They provide the exact pressure and smoothness required to eliminate bubbles and wrinkles during high-speed lamination.

Best for: Paper lamination, film coating, and textile processing.

Engineered to operate in continuous temperatures up to 300°C. These rollers maintain their elasticity and surface integrity under extreme thermal stress, preventing deformation.

Best for: Heat sealing, plastic extrusion, and drying processes.

Combining the structural strength of HDPE with a resilient rubber exterior, these rollers are built for high-load environments. They offer exceptional impact resistance and low friction.

Best for: Heavy-duty material handling, mining, and bulk conveying.

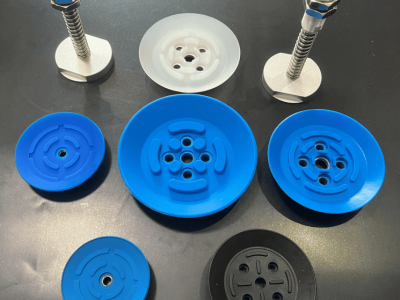

Technical Datasheet

| Item | Data | Item | Data |

|---|---|---|---|

| Inner Diameter | 10–300 mm | Out Diameter | 10–500 mm |

| Length | 1 m | Specific Gravity | 0.9 g/cm³ – 1.3 g/cm³ |

| Color | Pantone card and transparent | Hardness | 20–90 Shore A |

| Appearance | Smooth / Wave / Matte | Temperature | -60℃ – 350℃ |

| Tear Strength | Up to 25 MPa | Elongation | 300–650% |

| Deformation Rate | ≤ 9% | Anti-Flammable | FRAS approved |

| Acid and Alkali Resistance | Available | Inside core | Metal, plastic or without |

| Surface | Smooth or pattern, non-sticky | Resistant | Oil, chemical, heat |

| Materials | Silicone, silicone sponge, PU, HDPE | Food Grade | FDA approved |

| Medicine | Passed halogen test | Water Absorption | 0% for silicone, 80% for sponge |

| Aging Period | 1 year as exact environment | Chemical Safe | RoHS and SVHC certificate |

Why Choose Our Factory?

With over 11 years of specialized experience in silicone rubber roller and polyurethane roller manufacturing, our facility combines cutting-edge technology with artisanal precision.

Advanced Material Science: We use 100% virgin silicone polymers. Our heat-resistant formulas are tested to withstand continuous operation at 300°C without loss of elasticity.

State-of-the-Art Production: Our workshop is equipped with automated vulcanizing autoclaves and precision CNC grinders to ensure every coated surface is flawless.

Customized Solutions: From Heavy-duty HDPE cores to precision Laminating Machine rollers, we provide tailor-made solutions for the most demanding industrial environments.

Global Standards: Operating under ISO 9001:2015 standards, we guarantee traceability and consistency in every batch we ship to our global partners.

Precision Engineering

Dimensional Accuracy: “Our high-precision CNC grinding machines ensure a diameter tolerance of up to ±0.3mm and a run-out of less than 0.3mm.”

Hardness Control: “We offer a wide range of hardness from 20 Shore A to 90 Shore A, with a strict tolerance control of ±3 degrees to ensure consistent pressure.”

Dynamic Balancing: “For high-speed applications like lamination, every roller undergoes dynamic balancing tests to eliminate vibration and ensure smooth operation.”

Chemical Bonding: “We utilize advanced multi-stage surface treatment and high-strength bonding agents to ensure an inseparable bond between the silicone coating and the metal core.”

In-house Compounding: “Unlike resellers, we do our own in-house material compounding, allowing us to customize formulas for anti-static, oil-resistant, or extreme high-temperature requirements.”

Customized Rubber Rollers Factory in China

Full-Cycle Testing: “From raw material analysis to finished product inspection, every roller passes through a rigorous QC checklist, including Shore hardness testing, concentricity checks, and high-temperature aging simulations.”

Compliance: “All our food-grade rollers are FDA and RoHS compliant, ensuring zero contamination for pharmaceutical and food packaging lines.”

Problem Solvers: “We don’t just manufacture rollers; we solve production issues. Our Hot Stamping Rollers are optimized for maximum thermal conductivity to prevent uneven foil transfer.”

Customization: “Support for full OEM/ODM services. Send us your CAD drawings or technical specifications, and our engineering team will provide a DFM (Design for Manufacturing) analysis within 24 hours.”

SUCONVEY Service

With over 11 years of experience in the rubber industry, we possess a wealth of expertise. SUCONVEY is dedicated to solving the rubber challenges faced by industries worldwide.

Frequently Asked Questions

If your question is not listed, please contact us.

Hardness depends on the pressure and material you are processing. Generally, softer rollers (20-40 Shore A) are ideal for delicate laminating or uneven surfaces, while harder rollers (60-90 Shore A) provide the stability needed for high-pressure glue application or heavy-duty conveying. Our engineers can provide a recommendation based on your machine specs.

We offer a variety of cores including Stainless Steel, Carbon Steel, Aluminum, and specialized HDPE. We can also recoat your existing cores to save on shipping and material costs.

Yes. Beyond a standard smooth finish, we can provide precision-ground matte surfaces, mirror finishes, or specific grooved patterns (spiral, diamond, or longitudinal) to assist with material tracking or liquid distribution.

This is our core strength. We use a proprietary high-bond chemical priming process and controlled thermal vulcanization. This creates a molecular bond between the silicone and the core, ensuring the coating remains intact even under high-speed rotation and extreme heat.

To provide an accurate quote, we typically need:

Dimensions: (Total length, face length, and outer diameter).

Hardness: (Shore A).

Working Environment: (Operating temperature, chemical exposure, and load/pressure).

Core Requirements: (Material and shaft edge details/drawings).

Yes. We are an experienced exporter and supplier. All rollers are wrapped in protective film and packed in reinforced wooden crates to ensure they arrive in perfect condition, regardless of the destination.