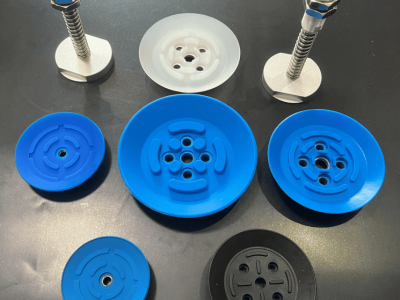

Silicone Rubber Gasket Seals

Various Types of Silicone Rubber Gaskets

Custom Silicone Rubber Seals Manufacturer

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Global Certifications

FDA: Non-toxic, odorless seals for food processing, complying with FDA 21 CFR 177.2600.

High-purity platinum-cured gaskets for surgical tools and lab equipment.

Peroxide-free seals designed for semiconductor and sensitive electronics manufacturing.

Advanced pneumatic technology that expands to provide a leak-proof seal for large, irregular gaps.

Filled with nickel-graphite or silver-aluminum for simultaneous sealing and electromagnetic shielding.

Featuring high-tack 3M™ adhesive backing for simplified, secure installation.

Precision die-cut washers for high-compression sealing in plumbing and machinery.

High-resilience sealing rings with exceptional thermal stability from -60°C to +230°C.

Filled with carbon black, nickel-graphite or silver-aluminum for simultaneous sealing and electromagnetic shielding.

Technical Datasheet

Item | Data | Item | Data |

Design | As drawing or sample | Specific Gravity | 0.9g/cm3~1.3g/cm3 |

Color | Pantone Card and transparent | Hardness | 20~90 Shore A |

Appearance | Smooth/Wave/Braided | Temperature | -60℃-350℃ |

Tear Strength | Up to 25 Mpa | Elongation | 300-650% |

Deformation Rate | ≤9% | Anti-Flammable | FRAS approved |

Acid and Alkali Resistance | Available | Insert Layer | Fabric or Canvas |

Stick Layer | 3M or Brush Glue | Food Grade | FDA Approved |

Medicine | Passed Halogen Test | Water Absorption | 0% for silicone, 80% for sponge |

Aging Teriod | 5 years under right environment | Chemical Safe | ROHS and SVHC certificate |

Advanced Sealing Technology for Critical Environments

At Suconvey, we don’t just manufacture gaskets, washers; we engineer sealing integrity. Our silicone seals are designed to perform under extreme conditions—ranging from high-vacuum medical environments to high-temperature industrial piping.

Using state-of-the-art CNC die-cutting and compression molding, we provide gaskets with tolerances as tight as 0.1mm, ensuring a perfect fit and long-term durability against heat, ozone, and chemical exposure.

Why Choose Us as Your Gasket Manufacturing Partner?

- Material Selection Expertise: Not sure which silicone grade to use? Our engineers analyze your media (acids, oils, steam) to recommend the optimal polymer.

- Precision Die-Cutting & Molding: We offer both high-speed die-cutting for flat gaskets and precision molding for complex 3D seals.

- In-House Tooling: Our internal mold-making shop reduces lead times for custom prototypes from weeks to days.

- Quality Assurance: Every batch undergoes strict dimensional inspection using automated optical measurement systems.

Your Trusted Silicone Gasket Seals Supplier in China

- Custom Compound Formulation: We don’t just buy off-the-shelf silicone. We can adjust the Shore A hardness, elongation, and chemical resistance of our compounds to suit your specific media (Steam, Oil, Acids).

- Compression Set Testing: We verify that our seals maintain their “memory” and sealing force even after long-term compression at high temperatures.

- Material Traceability: Every shipment is accompanied by a Certificate of Analysis (COA). We track every batch from the raw polymer to the finished gasket.

White-Glove Professional Service

- Design for Manufacturability (DFM) Support: Our engineers review your drawings and suggest optimizations to reduce costs and improve sealing performance.

- Rapid Sampling: Need to test a design? We offer 3-day rapid prototyping for die-cut gaskets to keep your project on schedule.

- Inventory Management: For long-term partners, we offer “Safety Stock” programs to ensure 24-hour dispatch for your most critical seal components.

SUCONVEY Service

With over 11 years of experience in the rubber industry, we possess a wealth of expertise. SUCONVEY is dedicated to solving the rubber challenges faced by industries worldwide.

Frequently Asked Questions

If your question is not listed, please contact us.

Yes, but we recommend high-purity or platinum-cured silicone to prevent outgassing, which can contaminate vacuum chambers.

Absolutely. We can match any RAL or Pantone color for aesthetic branding or color-coding for industrial safety.

For most industrial applications, a compression rate of 15% to 30% of the gasket’s original thickness is recommended to achieve a reliable seal. Over-compression (above 50%) can lead to “compression set” where the silicone loses its elasticity, while under-compression may result in leak paths. Our engineering team can help you calculate the exact clamping force required based on your housing material and internal pressure.

Inflatable seals are dynamic sealing solutions. Unlike static gaskets that require constant mechanical pressure, inflatable seals expand and contract using air pressure. They are ideal for applications with large or irregular tolerances, such as sliding doors, sterilizers, or cleanroom hatches, where they provide a hermetic seal that can be engaged or disengaged instantly.

Conductive silicone gaskets are essential when your device requires both an environmental seal (protection against dust/moisture) and EMI/RFI shielding. By loading the silicone with conductive particles (such as silver-aluminum or nickel-graphite), the gasket creates an electrical path between the enclosure parts, preventing electromagnetic interference from disrupting sensitive electronics.

Yes. We accept .STEP, .STP, .DWG, and .DXF files. For complex 3D seals, we use these files to create high-precision Liquid Injection Molds (LIM). For flat gaskets, we use the vector data for our Flash-Cutting (Die-less) machines, which allow us to produce complex shapes without the cost of a physical cutting die.