Custom Inflatable Silicone Rubber Gasket Seals

Inflatable Silicone Rubber Gasket Seals Manufacturer

Suconvey manufactures custom inflatable silicone gasket seals designed for applications where a traditional static gasket cannot provide consistent sealing due to tolerance variation, thermal expansion, door misalignment, vibration, or frequent open/close cycles.

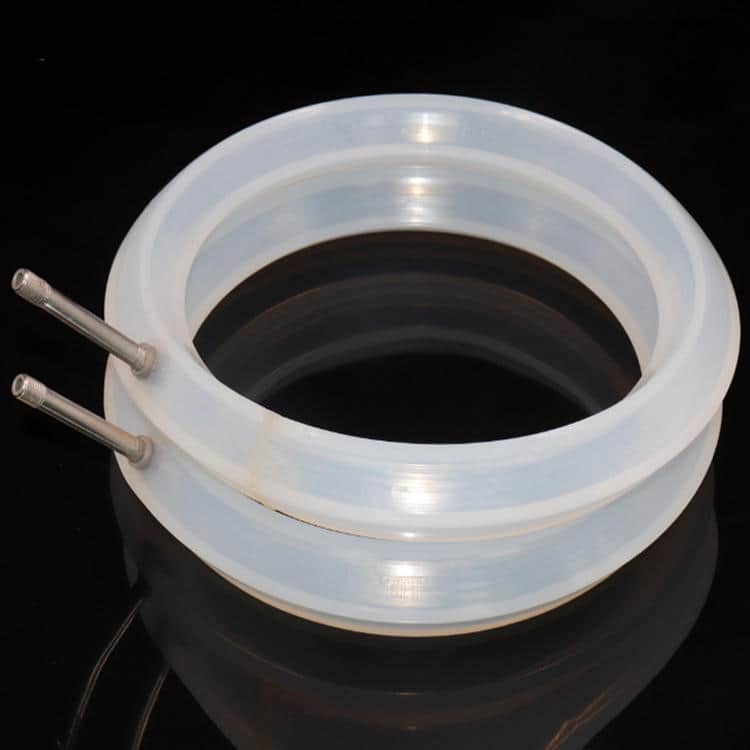

Inflatable silicone seals create a reliable seal by inflating with air (or inert gas) after the door/lid closes, forming uniform contact pressure around the sealing surface. When deflated, friction is reduced—helping protect the seal and improving service life.

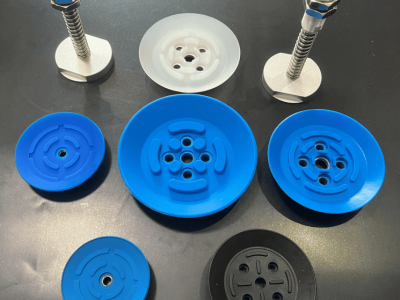

Custom Inflatable Rubber Gasket Seals

An inflatable silicone gasket seal is a hollow silicone sealing profile (often with a molded or bonded valve/air inlet). Once installed, the gasket remains in position and inflates to:

- compensate for uneven gaps

- seal large tolerances

- reduce clamping force requirements

- provide repeatable sealing for frequent cycling

This is widely used in industrial doors, chambers, autoclaves, ovens, containment enclosures, and equipment requiring airtight or watertight sealing.

Product Details

Custom Silicone Inflatable Seal Rings Factory

Key Features

1) Reliable sealing despite tolerance variation

Inflation enables the gasket to fill gaps and maintain contact pressure even when the sealing surface is not perfectly flat.

2) Lower mechanical wear and longer life

Deflation reduces drag and abrasion during opening/closing compared with static compression seals.

3) Excellent high/low temperature performance

Silicone remains flexible across wide temperature ranges, supporting thermal cycling and harsh environments.

4) Custom geometry for complex frames

Profiles can be engineered for rectangular doors, circular lids, irregular contours, or special installation channels.

China Custom Inflatable Silicone Gasket Seals Manufacturer

Typical Applications

Custom inflatable silicone gasket seals are commonly used in:

- Vacuum or pressure chambers (project-dependent sealing level)

- Industrial ovens and thermal chambers

- Autoclaves and sterilization equipment (project-dependent)

- Clean enclosures, isolation boxes, glove boxes

- Food processing doors and access hatches

- Drying cabinets, coating lines, and containment equipment

- Inspection windows and frequently opened lids requiring repeatable sealing

If your system has a target leak rate, temperature cycle profile, or chemical exposure, share it with us—we’ll recommend the best profile and compound direction.

Customization Options

We can manufacture inflatable silicone seals based on drawings, samples, or functional requirements:

Profile & Size

- Custom cross-section (round / D / P / rectangular / multi-lip)

- ID/OD / wall thickness / inflation cavity design

- Corner solutions: molded corners or bonded corners for clean fit

Inflation Design

- Air inlet / valve location (single point, multiple points)

- Inflation direction and contact surface geometry

- Leak-resistance design for long hold time

Material & Performance

- Standard silicone for industrial use

- Food-grade silicone / high-purity options

- Optional requirements: aging resistance, ozone/UV resistance, low compression set, low outgassing (project-based)

Installation

- Groove/channel fit designs

- Adhesive backing options (if required)

- Mounting holes / clips / mechanical retention design (project-based)

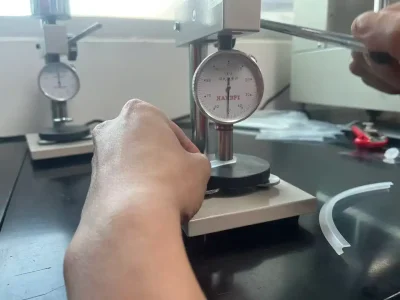

Quality Control & Production Capability

We support both prototype development and batch production:

Dimensional verification

Visual inspection (surface/defects)

Airtightness / leak check options (per project requirement)

Batch traceability and custom labeling

Export packaging

How to Request a Quote

To quote and engineer the right seal, please provide:

- Frame inner dimensions / perimeter length

- Cross-section target (or available groove size)

- Working temperature range

- Inflation pressure target (or available air supply)

- Seal media: air / inert gas; environment exposure (steam/chemical/oil)

- Opening/closing cycle frequency

- Compliance requirement (food contact, etc.)

- Quantity and target lead time

Send your drawing or sample—our team will propose a manufacturable design and a cost-effective plan.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone inflatable seals are wrapped with protective film to prevent dust, moisture, and surface damage. Several are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test seals can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Please provide frame dimensions/perimeter, available groove size, gap range, operating temperature, inflation pressure (or air supply capability), cycle frequency, and any exposure to steam/chemicals/oils. A drawing or sample will speed up development.

When inflated, the seal expands to fill variable gaps and applies uniform contact pressure, which helps maintain sealing even if the door or surface is slightly misaligned or not perfectly flat.

Yes. Molded corners provide cleaner fit, improved sealing continuity, and better durability for rectangular frames. Bonded corners are also available depending on design and cost targets.

Inflation pressure depends on the profile, gap range, and target sealing force. We can recommend a suitable pressure window after reviewing your cross-section and application conditions.

Yes. Silicone is suitable for high/low temperatures and thermal cycling. Share your actual operating temperature curve and cycle time so we can recommend the most appropriate compound and profile design.

Standard inspection includes dimensional and visual checks. Leak checks and airtightness tests can be provided per project requirement, especially for chamber/enclosure sealing applications.

MOQ varies depending on profile complexity and whether molded tooling is required. We can support prototypes and small-batch trials before mass production. Lead time is determined by design complexity, tooling, and quantity.