Custom Silicone Extruded Profiles & Sealing Strips

Various of Silicone Rubber Strip Seals Types

Silicone Extruded Profiles Manufacturer in China

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

Featuring 3M™ or specialty PSA backing for quick, permanent installation.

Oven door seals

Heavy-duty, steam-resistant seals for commercial and home baking units.

Window seals

Weatherproof, UV-resistant strips for architectural and automotive glazing.

Refrigerator doors seals

Antimicrobial, low-temperature flexible seals for cold storage and appliances.

Technical Datasheet of Silcone Extruded Profiles

Item | Data | Item | Data |

Design | As drawing or sample | Specific Gravity | 0.9g/cm3~1.3g/cm3 |

Color | Pantone Card and transparent | Hardness | 20~90 Shore A |

Appearance | Smooth/Wave/Braided | Temperature | -60℃-350℃ |

Tear Strength | Up to 25 Mpa | Elongation | 300-650% |

Deformation Rate | ≤9% | Anti-Flammable | FRAS approved |

Acid and Alkali Resistance | Available | Insert Layer | Fabric or Canvas |

Stick Layer | 3M or Brush Glue | Food Grade | FDA Approved |

Medicine | Passed Halogen Test | Water Absorption | 0% for silicone, 80% for sponge |

Aging Teriod | 5 years under right environment | Chemical Safe | ROHS and SVHC certificate |

Your Trusted Silicone Extruded Profiles Supplier

At Suconvey, we specialize in the continuous extrusion of premium silicone rubber strips and profiles. Our technology allows us to maintain tight tolerances and produce infinite lengths for seamless sealing.

From UV-resistant window seals to steam-resistant oven gaskets, our strips are formulated to maintain their elasticity and sealing integrity in the harshest environments. We offer a full range of Shore A hardness and custom color matching to meet your specific design requirements.

Advanced Material Science & Compounding

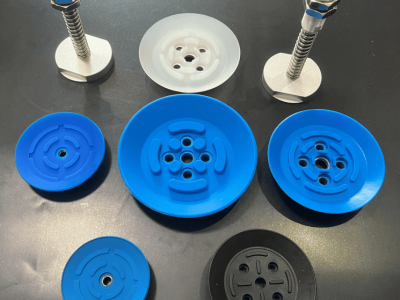

Custom Shore A Hardness: We offer a full spectrum of hardness from Ultra-Soft (30 shore A) for delicate electronic seals to High-Density (80 shore A) for heavy-duty industrial wear-strips.

Specialized Formulations:

High-Temp Stabilized: Maintains elasticity at a constant 300°C (572°F).

Steam Resistant: Optimized for commercial oven and autoclave environments.

Low-Temperature Flexibility: Remains pliable at -60°C, perfect for industrial refrigerator gaskets.

Best Silicone Sealing Strip Company in China

Custom Die Fabrication: We design and cut our own extrusion dies in-house. This allows us to go from a CAD drawing to a physical sample in as little as 3–5 days.

DFM (Design for Manufacturability) Support: Our engineers review your profile designs (T, D, U, E, etc.) to optimize the geometry for better sealing performance and lower production costs.

- Precision Cutting: We offer automated “Cut-to-Length” services with high-speed guillotines, ensuring clean, square edges with no fraying.

The Science of Shape

Solid Seals vs. Hollow Seals:

Solid profiles are better for high-pressure industrial sealing where maximum durability is required.

Hollow profiles (D-shape, E-shape) are designed for low-closure force. They collapse easily to fill irregular gaps without putting stress on hinges or latches.

Compression Set:

Tip for Engineers: Designing for 20%-30% compression is ideal. Over-compression leads to material fatigue and seal failure.

Common Design Mistakes to Avoid

Mistake 1: Designing sharp internal corners (leads to tearing).

Fix: Use a minimum radius of 0.5mm.

Mistake 2: Ignoring the bend radius.

Fix: For window seals, ensure the profile doesn’t buckle at the corners.

Mistake 3: Not considering air pressure in hollow bulbs.

Fix: Add small “vent holes” to allow air escape during compression.

SUCONVEY Service

With over 11 years of experience in the rubber industry, we possess a wealth of expertise. SUCONVEY is dedicated to solving the rubber challenges faced by industries worldwide.

Frequently Asked Questions

If your question is not listed, please contact us.

Yes. We specialize in custom OEM profiles. You can send us your CAD drawing (STP or DXF), and we can create a custom extrusion die for your project.

Solid silicone strips are high-density extrusions with high tensile strength and tear resistance, making them ideal for high-pressure industrial seals and mechanical gaskets.

Silicone sponge (foam) strips have a closed-cell structure, making them much softer and more compressible. Sponge is preferred for lightweight enclosures, door seals with low closing force, and applications requiring thermal insulation.

Yes. We specialize in custom profile extrusion. We can manufacture complex geometric shapes based on your CAD drawings.

Our in-house tooling shop can create custom dies for T-shaped edging, D-profile hollow seals, U-channel glass protectors, and E-shaped oven gaskets, ensuring the profile matches your specific track or groove dimensions perfectly.

Our standard silicone strips are rated for constant use up to 230°C (446°F). However, for specialized industrial applications like furnace doors or commercial ovens, we offer Heat-Stabilized Silicone that can withstand constant temperatures of +300°C (572°F) without losing flexibility or becoming brittle.

Yes. Silicone is the superior material for outdoor use compared to EPDM or PVC. It is naturally resistant to UV radiation, ozone, and extreme oxidation. Our window sealing strips can remain in service for over 10–20 years outdoors without cracking or shrinking, even in intense sunlight or sub-zero temperatures.

Silicone is naturally “non-stick,” so applying adhesive is a specialized process. We use a plasma or chemical primer treatment on the silicone surface before applying high-performance tapes like 3M™ VHB or 9448A. This creates a permanent chemical bond that prevents the adhesive from peeling off, even in high-temperature or humid environments.