PVC and silicone materials have many different advantages in the production process, especially in our daily life. Moreover, different industries also have different requirements for the selection of materials. Only by comprehensively understanding the nature and differences of products can we make better choices. Today, with the help of this article, let’s approach their world and explore their differences.

Introduction of pvc rubber

The form of PVC is white powder and the structure is uncertain. Its relative density is about 1.4. It can be vitrified only when the temperature reaches 77 ~ 90 ℃, and it can be decomposed only when the temperature reaches about 170 ℃. PVC has poor stability to light and heat. For example, when the temperature reaches more than 100 ℃ or is exposed to the sun for a long time, it will decompose to produce hydrogen chloride. If it continues under this condition, it will further catalyze and decompose, resulting in discoloration.

At the same time, its physical and mechanical properties will also decline. Because of this characteristic, we usually need to add a certain amount of stabilizer in actual operation and use to ensure that it can work normally under light and heat conditions. In general industrial industries, the molecular weight of PVC is usually between 50000 ~ 110000, and the molecular polydispersity is strong, but the molecular polymerization will gradually increase with the decrease of temperature; Due to its unstable molecular characteristics, PVC has no fixed melting point. It generally begins to soften at 80 ~ 85 ℃, but when the temperature reaches 130 ℃, it will become viscoelastic state.

When the temperature reaches 160 ~ 180 ℃, it will begin to change into viscous flow state; PVC has good mechanical properties, with tensile strength of about 60MPa and impact strength of 5 ~ 10kj / m2; It also has good dielectric properties. PVC used to be the world’s largest general-purpose plastic, so it has a wide range of applications. The scope of application includes: building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging film, bottles, foaming materials, sealing materials, fibers, etc.

Introduction of silicone rubber

Silicon dioxide is the main component of silicon dioxide. Silicone is a polymer made from silicon and oxygen. Silicon is a natural element that is the second most abundant in the earth’s crust, after oxygen. Silicon does not occur naturally as a polymer; it must be combined with other elements to form polymers. Silicone has many applications, both industrial and consumer. PVC is a material that has been used in construction for decades, while silicone is a newer material that has been gaining in popularity.

The chemical formula of silicone is xsio2 · yh2o, which is transparent or milky white solid particles. The utility model has an open porous structure and strong adsorption capacity for various substances. Dilute sulfuric acid (or hydrochloric acid) is added to the aqueous solution of glass water to stabilize it, so as to form silica gel solid water. Silica gel can be obtained by removing Na + and SO42 – (CL) ions from the electrolyte by water washing. As hygroscopic agent, the hygroscopic rate of some silica gel is about 40%, or even 300%. It is used for gas drying, gas absorption, liquid chromatography, etc. it can also be used as a catalyst. If cobalt chloride is added, blue and red water will be absorbed after drying. recycling.

What are the Differences between PVC and Silicone?

General comparison:

- PVC products are made of PVC, petroleum and color paste. The raw materials are heated and cooled by micro injection molding process. Silica gel, which only uses chemical components such as silica gel plus color masterbatch, is put into the mold by rubber calendering and refining machine, and then heated and cooled by oil pressure.

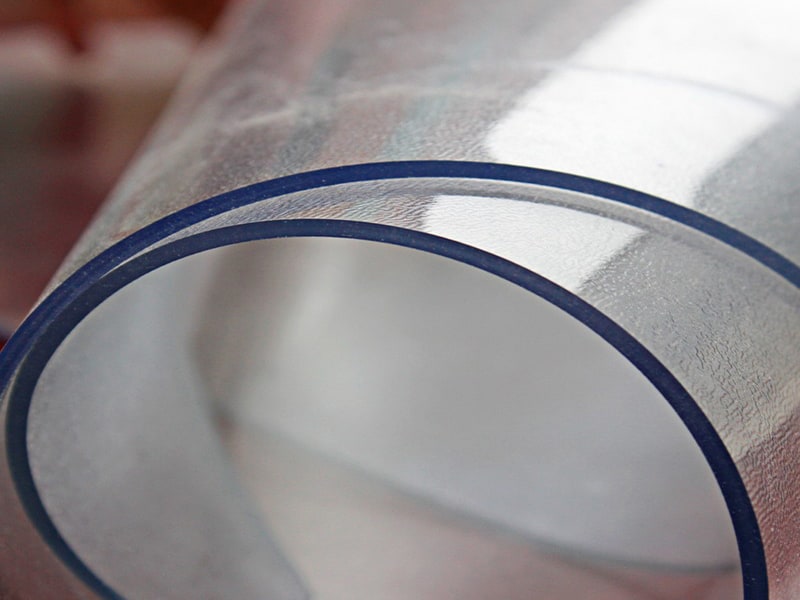

- In terms of appearance, PVC products are coarser than silicon products, with smooth surface and bright color.

- According to tactile judgment, silica gel products are soft, with good hardness and elasticity. PVC is soft and relatively hard, both soft and hard, adjustable but not hard PVC.

- PVC is a common environmental protection material, also known as atbc-pvc. Silica gel can pass ROHS certification and is environment-friendly.

- Silicone products are generally transparent and have little burning smell. The products are in powder shape. Plastic products will produce black after burning, and the burning smell is unpleasant.

- Silica gel products have higher heat and cold resistance in PVC products. Silica gel products can be heated in microwave oven, while PVC products cannot.

And there are some specific details comparison:

Strength: PVC is stronger than silicone, making it a good choice for applications that require durability.

Temperature Resistance: silicone is more resistant to high temperatures than PVC, making it a better choice for applications that require heat resistance.

Flexibility: PVC is more flexible than silicone, making it a better choice for applications that require movement.

Transparency: PVC is less transparent than silicone, making it a better choice for applications that require visibility.

Cost: PVC is less expensive than silicone, making it a better choice for budget-conscious.

-Think about what you are using the material for. If you are looking for something to use outdoors, you will need something that can withstand the elements.

-Consider your budget. Some materials are more expensive than others.

-Think about how much time you want to spend on the project. Some materials are easier to work with than others.

-Check out the different options available. There are many types of materials to choose from, so take your time and find the one that is best for you.

Conclusion:

There are many differences between PVC and silicone rubber. The above are the main differences. They have many differences. The selection of specific materials requires us to choose according to our own product types. Because different products have different applicability to raw materials, especially in some industries, the specificity of materials also needs to be carefully considered before selection.Conclusion: PVC and silicone have different pros and cons, so it is important to consider what you need before deciding which type of plastic is best for your application.

In addition, compared with other polymer materials, PVC has the advantages of low price, wide source of raw materials, simple manufacturing process, insulation and flame retardant. At the same time, the utility model can be recycled and has the effect of sanitation and environmental protection. But if you need food grade tube materials, silica gel is more convenient. Choosing suitable and high-quality suppliers is undoubtedly an important decision of any enterprise. Bai-OTT can provide you with two products and services with quality assurance, which can meet your needs. After our wishes, you are welcome to contact us.