Introduction

Rubber rollers are a type of roller that is used in various machines and applications. There are several different types of rubber rollers, which each have their own unique benefits and uses.

Types of rubber rollers

Rubber rollers are commonly used in many industrial and commercial applications. There are several types of rubber rollers that are available on the market. The most common type of rubber roller is the solid rubber roller. Solid rubber rollers are made from a single piece of rubber and they are the most common type of roller used in conveyor systems. Rubber rollers can be manufactured from flexible materials, but these rollers are called flexible rubber rollers. Rubber rollers can also be manufactured from rigid materials such as steel. Rubber rollers are used in rubber processing and rubber industry applications because they are durable, provide a good surface for contact with other materials, and can be easily cleaned. Rubber rollers are also used in many industries including tire manufacturing, food packaging, paper making, textile manufacturing and printing. The type of application will determine the type of material that is used to manufacture the roller. And we can manufacture high quality, hot press coated silicone rubber rollers and rubber rollers in China. They are often used in printing presses, packaging machines, and other manufacturing equipment. In addition, rubber rollers are also common in commercial settings such as restaurants and grocery stores.These rubber rollers are common made of many materials including rubber, silicone rubber, and stainless steel.

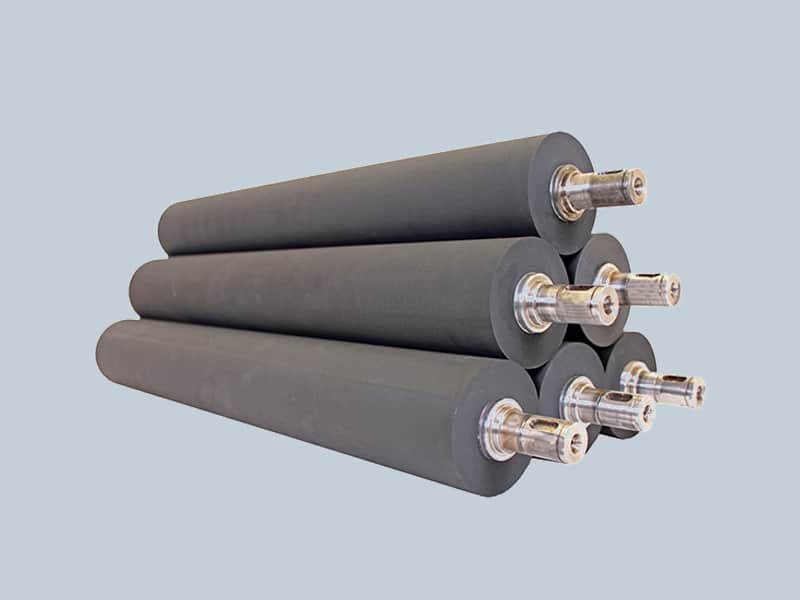

Solid rubber rollers

Solid Rubber Rollers are the perfect solution for a wide range of industrial and commercial applications where high quality, durable roller products are required. Constructed from a solid piece of rubber, our rollers are tough and long lasting. They provide excellent resistance to wear, abrasion, and corrosion and can handle a large range of temperatures without degradation. Additionally, they are non-marking and non-skidding, making them ideal for use in a variety of settings.

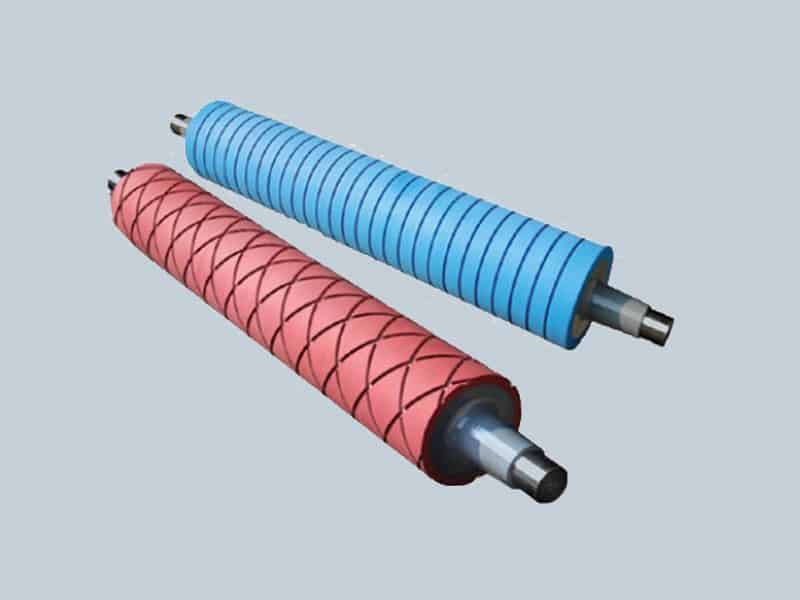

Tapered rubber rollers

In industrial and commercial settings, tapered rubber rollers are often used to apply pressure or traction to a variety of surfaces. In some cases, the rubber is heated in order to provide better adherence to the material being worked on. Tapered rubber rollers are also used in printing presses, as they can help to create an even print surface.

crowned rubber rollers

The crowned rubber roller is a device that has been used for centuries to apply pressure to an object in order to achieve a desired result. The modern incarnation of the crowned rubber roller is made of middle-high rubber that is vulcanized on a metal bearing. The bearing is then fitted with either a handle or a motor, allowing the user to apply pressure evenly over a large area to help the roller transportation force always in the center of the roller.

Sponge rubber rollers

Sponge rubber rollers are made of an open-celled foam rubber. They are used in a variety of applications, including the printing and textile industries. Sponge rubber rollers are also used in the construction industry to apply adhesives and coating.

Pneumatic rubber roller

This type of roller is powered by air pressure and is used in applications that require high speed and accuracy, such as printing and coating.

Manual rubber roller

This type of roller is operated by hand and is used in applications where low speed or even no movement is required, such as in painting or adhesive application.

Hydraulic rubber roller

This type of roller is powered by hydraulics and is used in applications where high speed and accurate movement are required, such as in printing or coating.

Vacuum rubber roller

This type of roller is powered by vacuum and is used in applications that require high speed and accuracy with a very low weight, such as in printing or coating. In the past, rubber rollers have been manufactured using a variety of materials, such as wood and metal. These materials are unsuitable for cost-effective production because they are expensive and difficult to machine.

Flat Rollers

These are the most common type of rubber roller and are used for rolling out dough, modeling clay, and other materials.

Cylinder Rollers

These rollers have a cylindrical shape and are used for pressing clothes or other materials. They can also be used for shaping products, such as doughnuts or cookies.

Belt Rollers

These rollers have a band or belt like shape and are used for rolling out dough, modeling clay, sugar dough, cookie dough, and other materials. They are also frequently used in crafting projects.

Rotary Rollers

These are used for forming flat and round shapes. They are also frequently used in crafting projects.

Advantages of rubber rollers:

Rubber rollers have been used in various industrial applications for many years and continue to be a popular choice for conveying and processing a wide range of materials. They are available in a variety of sizes, shapes, and durometers to meet the needs of almost any application. Here are some of the most common reasons why rubber rollers are such an integral part of industrial processes:

1. Rubber is an extremely versatile material that can be adapted to suit a wide range of applications.

2. Rubber rollers are tough and durable and come in a variety of sizes and can withstand significant wear and tear.

3. They provide good traction, which helps to ensure smooth, efficient conveyance of materials.

4. Rubber is resistant to heat and moisture, making it ideal for use in applications where these factors are present.

Conclusion

Rubber rollers are an important part of many machines and applications. There are several different types of rubber rollers, each with their own unique benefits and uses. If you have any questions, please contact us for free.