Silicone Products Manufacturer

Learn about the variety of SILICONE products for machinery that SUCONVEY services.

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

Silicone Rubber(VMQ)

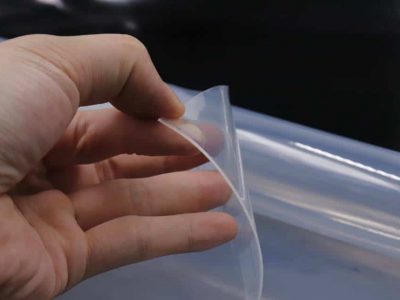

Silicone is a synthetic elastomer known for its exceptional versatility and performance in extreme conditions. It is composed of silicon, oxygen, carbon, and hydrogen atoms, and is prized for its thermal stability, chemical resistance, and flexibility across a wide range of applications. Unlike many other rubber materials, silicone maintains its properties across both high and low temperatures without losing its elasticity or strength.

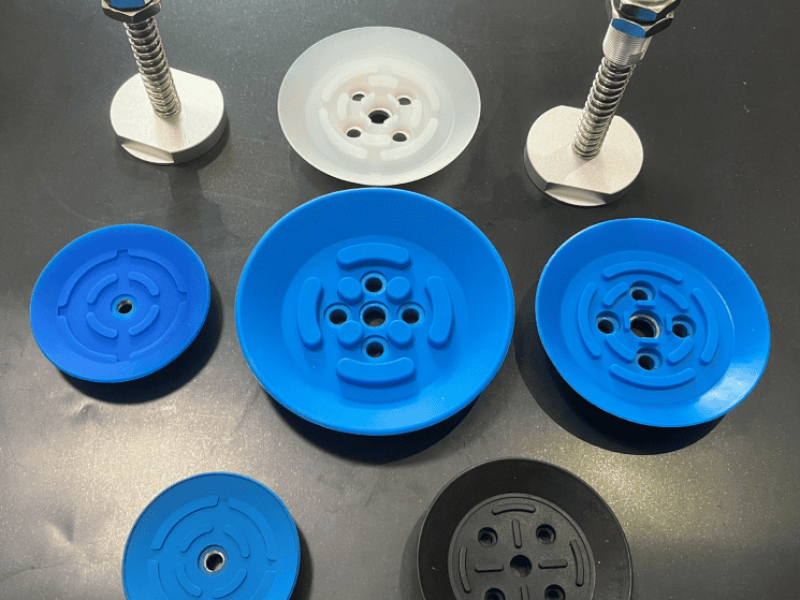

Explore premium silicone products including silicone sheets, silicone tubes, silicone gaskets, vacuum bags, suction pads and custom silicone components for automotive, food, medical, and industrial applications.

SUCONVEY Service

With nine years of experience, we have provided countless silicone product solutions to numerous clients. We possess extensive experience in addressing challenges in the manufacturing of rubber and polyurethane products.

SUCONVEYChina Silicone Products Manufacturer

We don’t just manufacture silicone; we provide peace of mind. By combining premium raw materials with certified quality management and bespoke customization, we ensure that our silicone sheets, tubes, and rollers perform flawlessly in the most demanding environments.

Expertise and Experience

With over 9 years in silicone manufacturing, we understand the unique demands of various industries, from medical and food processing to automotive and mining, industrial engineering.

High quality raw materials

We prioritize Platinum-Cured silicone for applications requiring zero odor and high clarity. Our materials are 100% virgin, ensuring no fillers, no toxins, and maximum service life.

Product Certificate

Our products are fully certified to meet international safety standards, including FDA (USA), LFGB (Germany), REACH, and RoHS.

Customized services

Our in-house R&D team supports OEM/ODM services. Whether you provide a 3D drawing (STP/IGS) or just a physical sample, we can develop custom molds and prototypes within 7-10 days. We offer full customization for Hardness (10A – 80A Shore A), Colors (Pantone/RAL matching), and Dimensions.

Quality Assurance

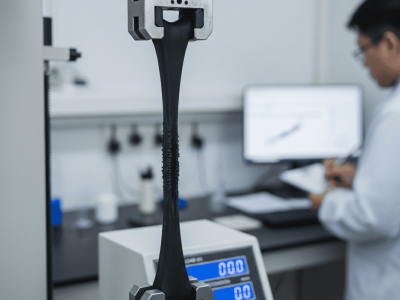

We implement a strict IQC-IPQC-FQC inspection process. Every batch undergoes tensile strength, compression set, and accelerated aging tests in our professional lab.

Comprehensive after-sales service

In case of installation or usage problems, technical engineers can respond within 12 hours, providing on-site troubleshooting and improvement suggestions. Establish customer files and conduct regular follow-ups on product operation. Based on the needs of machinery and equipment upgrades, assist customers in product iteration development and cost reduction.

Why Silicone, not Other rubber or plastic?

Why choose silicone products? What are the uses of silicone? Silicone products are closely related to our lives. From children’s silicone toys and silicone tubes in beverages to silicone sealing strips in ovens and suction cups for robotic arms, silicone is an indispensable and irreplaceable material. The reasons are as follows:

High Temperature Resistance: Performs reliably from -50°C to +250°C (specialty grades can reach 300°C). This is one of the many reasons why our customers choose silicone products.

Non-Toxic & Odorless & Food grade & Medical grade: Contains no harmful chemicals like BPA, phthalates, or lead. Easily formulated to meet FDA, LFGB, and REACH standards. Many customers in the food and medical industries choose this non-toxic and odorless silicone, which is food-grade certified.

Flexibility & Elasticity: High elongation and flexibility, allowing it to be used in complex shapes and tight-radius seals.

Stability: Silicone does not become brittle in extreme cold or soft in extreme heat.

UV & Ozone Resistance: Excellent immunity to UV radiation, ozone, and oxidation, preventing cracking or chalking over time.

Inertness: Does not react with food or beverages and does not support bacterial growth.

Low Compression Set: Maintains its shape and sealing force even after long-term compression, which is vital for silicone strips and gaskets.

- Wide range of hardness: We can produce silicone products with hardnesses ranging from 10 Shore A to 85 Shore A. Whether you want something soft or hard, we can customize it for you.

| Feature | Silicone (VMQ) | EPDM / NBR / NR | PVC (Plastic) |

|---|---|---|---|

| Temp Range | -60°C to +250°C | -20°C to +120°C | -10°C to +60°C |

| Durability | 20+ Years | 5–10 Years | 2–5 Years |

| Food Safety | FDA/LFGB Approved | Difficult/Rare | Often Toxic |

| Elasticity | High & Stable | Moderate | Low (Hardens) |

| UV/Ozone Resistance | Excellent | Good to Poor | Poor (Chalks) |

High Quality Silicone Products Supplier

Customer Support

SUCONVEY customer specialists are devoted to providing flexible rubber products for machinery solutions for clients worldwide. Always keep you posted about the latest trend and technology. And we’re happy to give you a heads up for price changes!

Delivery Service

Our logistics teams are dedicated to providing expert service for all regions. We strive to maintain long-term relationships with shipping lines and agents.

Frequently Asked Questions

If your question is not listed, please contact us.

Yes. We use high-purity silicone that can be formulated to meet FDA, LFGB, and REACH/RoHS standards. Our products are non-toxic, odorless, and BPA-free, making them ideal for food, beverage, and healthcare applications.

Our standard silicone products perform reliably from -60°C to +230°C. For specialized applications, such as turbo hoses or industrial rollers, we can provide high-temp grades that withstand up to 300°C for short periods without losing flexibility.

Inferior silicone often smells due to cheap curing agents or a lack of post-curing. We utilize a post-curing process (secondary vulcanization) for several hours to eliminate volatiles and odors, ensuring our products are completely odorless and stable before they reach you.

Yes! We offer custom color matching based on Pantone or RAL color codes. Whether you need a high-transparency tube or a vibrant orange silicone roller, we ensure consistent color across different production batches.

We offer a wide range of hardness from 10 Shore A (very soft/gel-like) to 85 Shore A (firm/hard). Our experts can recommend the ideal hardness based on your application, such as sealing (soft) or heavy-duty rollers (hard).

Definitely. We have an in-house engineering team and mold-making center. We can work with STP, IGS, or PDF files to create custom-extruded strips, molded sheets, or precision-ground rollers tailored to your exact specifications.

We stand by our Quality Assurance. If a product fails to meet the agreed-upon drawings or material standards, we provide a full analysis and offer free replacement or a refund within 30 days of delivery.