Industrial Rubber Products

Learn about the variety of rubber products that SUCONVEY services.

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

SUCONVEY Service

Silicone is for “Heat/Purity” and PU is for “Wear/Toughness,” Rubber is the “All-Round Sealing King” and the most “Cost-Effective” solution. For conveyor belts spanning kilometers, Polyurethane is cost-prohibitive, and Silicone lacks the structural strength.

SUCONVEYRubber Products Manufacturer in the industry

Rubber can be specifically engineered for FRAS (Fire Resistant Anti-Static) properties, which is a mandatory safety requirement for underground mining. While Silicone is fire-resistant, it cannot handle the heavy abrasion of coal or ore. Rubber offers both safety and ruggedness.

Expertise and Experience

With over 9 years of focus on conveyor systems, we don’t just manufacture rubber; we understand the mechanical stresses of mining, quarrying, and port logistics.

High quality raw materials

We use high-purity Natural Rubber (NR) for superior elasticity and SBR/NBR blends for maximum resistance to abrasion, heat, and oil.

Product Certificate

We provide FRAS (Fire Resistant Anti-Static) certified rubber specifically for underground mining, ensuring compliance with the strictest safety regulations worldwide.

Customized services

Beyond belts, we provide custom-sized Pulley Lagging, tailored super belt screw lengths, and Vulcanizing Machines built to your specific voltage and belt-width requirements.

Quality Assurance

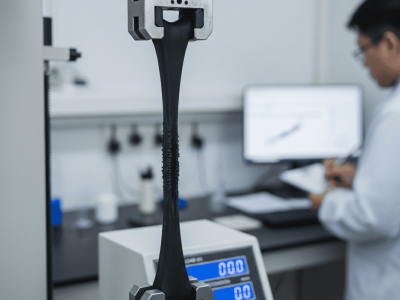

Our Vulcanizing Machines undergo pressure and temperature uniformity tests to guarantee a “stronger than the belt” splice. Every roll of conveyor belt is tested for tensile strength, cover adhesion, and abrasion loss (mm³) in our in-house lab before shipment.

Comprehensive after-sales service

We offer 24/7 remote guidance and on-site technical training, keeping your production lines moving and your maintenance costs low, providing on-site troubleshooting and improvement suggestions. Establish customer files and conduct regular follow-ups on product operation.

More Than Just a Rubber Products Manufacturer

Customer Support

SUCONVEY customer specialists are devoted to providing flexible rubber products for machinery solutions for clients worldwide. Always keep you posted about the latest trend and technology. And we’re happy to give you a heads up for price changes!

Delivery Service

Our logistics teams are dedicated to providing expert service for all regions. We strive to maintain long-term relationships with shipping lines and agents.

Frequently Asked Questions

If your question is not listed, please contact us.

Absolutely. We can provide detailed video training, manuals, or even send a technical expert to your site to train your team.

Yes. All our conveyor belts and vulcanizing equipment come with a standard 12-month warranty against manufacturing defects. We also provide technical support and installation guidance to ensure your system reaches its maximum service life.

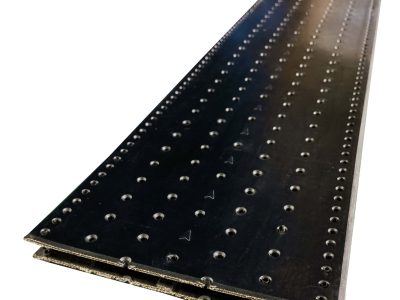

Rubber Lagging: Best for standard conditions and smaller pulleys.

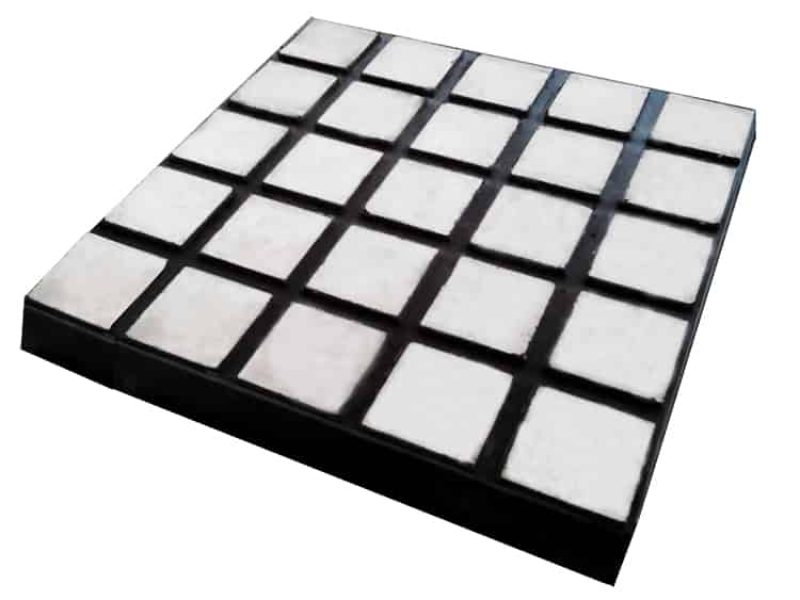

Ceramic Lagging: Recommended for high-tension, wet, or muddy conditions where the pulley is prone to slipping. The ceramic tiles provide a “positive grip” that significantly increases the friction coefficient.

Our machines utilize integrated water/air pressure bags and precision PLC controllers. This ensures that the pressure is distributed evenly across the belt surface (no “dead spots”) and the temperature is controlled within ±2°C, which is vital for a high-quality rubber bond.

Yes. We offer fully customizable Pressure Bags and Heating Platens. Whether you operate on 220V, 380V, 440V, and whether your belt is 600mm or 3000mm wide, we can build a machine to fit your specific mine or factory requirements.