Wear Resistant Polyurethane Products Manufacturer

Learn about the variety of polyurethane products that SUCONVEY services.

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

Polyurethane (PU)

Polyurethane (PU) is a versatile elastomer known for exceptional abrasion resistance, impact strength, high load capacity and chemical resistance. It can be molded into parts such as mats, rollers, hoses and custom industrial components for harsh environments.

Discover a comprehensive range of polyurethane products including PU mats, sheets, rollers, hoses, and custom polyurethane parts designed for industries such as mining, automotive, and conveyor systems. Enhance efficiency and durability with SUCONVEY’s engineered solutions.

| Performance Feature | Polyurethane (PU) | Standard Rubber |

|---|---|---|

| Abrasion Resistance | Superior (3-5x longer life) | Moderate / Standard |

| Load-Bearing Capacity | Extremely High | Low to Moderate |

| Tear & Impact Strength | Exceptional (Heavy Duty) | Fair (Prone to gouging) |

| Oil & Chemical Resistance | Excellent | Poor (Swells easily) |

| Hardness Range | Wide (10A to 85D) | Narrow (30A to 90A) |

| Service Life | Maximum (Reduced NPT) | Short (Frequent replacement) |

SUCONVEY Service

While silicone excels in heat resistance, polyurethane is unbeatable when it comes to toughness, load-bearing, and extreme abrasion resistance.It plays a pivotal role in the industry and mining sector.

SUCONVEY - Polyurethane Products Manufacturer

Stop settling for frequent replacements. Switch to our high-performance Polyurethane solutions and extend your equipment life by up to 5x. Our engineers are ready to help you select the perfect Shore hardness and formulation for your specific industrial application. Let’s solve your wear challenges together.

Expertise and Experience

With over 9 years of manufacturing experience, we specialize in high-wear environments, including mining, material handling, and oil & gas. We don’t just sell parts; we solve problems.

High quality raw materials

Unlike standard rubber, our PU is engineered for specific properties—whether you need extreme abrasion resistance for belt cleaners or high rebound resilience for industrial rollers.

Product Certificate

Our products comply with REACH and RoHS standards. For specialized applications, we offer Flame Retardant and Anti-Static formulations that meet mining safety regulations (such as MA or MSHA).

Customized services

With our own CNC machining and mold-making center, we can produce custom PU pipes, wheels, plates or heteromorphic parts from your 2D/3D drawings with high precision and fast turnaround.

Quality Assurance

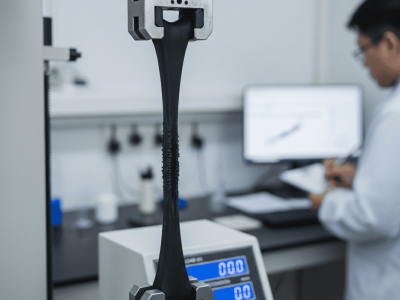

For PU-to-Metal products (like rollers and wheels), we use a multi-stage chemical bonding process that ensures the bond strength exceeds the strength of the polyurethane itself.

Comprehensive after-sales service

Our engineers provide on-site or remote guidance for product selection and installation to maximize your equipment’s uptime.

Key Advantages of SUCONVEY's Polyurethane Products

- Superior Abrasion Resistance: It outlasts rubber, plastic, and even some metals in high-friction environments. Polyurethane has a remarkably low wear rate. It is specifically designed to handle the constant scraping of belt cleaners and the high-speed friction of industrial rollers.

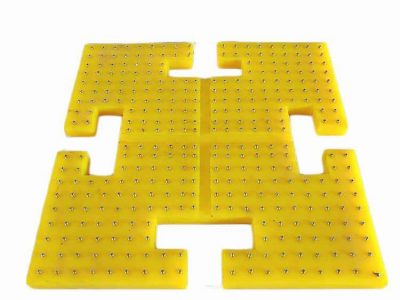

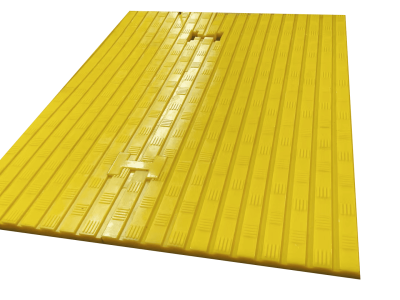

- Exceptional Impact & Tear Resistance: It can absorb high-energy impacts without cracking or tearing. This makes it the perfect material for impact beds and anti-slip mats on drill floors or mining sites where heavy tools or rocks are frequently dropped.

- Oil, Chemical & Solvent Resistance: Polyurethane is naturally resistant to oils, fats, greases, and many chemicals.

- “Kind” to Mating Parts (Belt Protection): Despite its hardness, PU has a lower coefficient of friction against belts compared to metal. In belt cleaners and skirting, PU removes debris efficiently without gouging or wearing down the expensive conveyor belt.

Your Trusted Polyurethane Products Supplier

Customer Support

SUCONVEY customer specialists are devoted to providing flexible rubber products for machinery solutions for clients worldwide. Always keep you posted about the latest trend and technology. And we’re happy to give you a heads up for price changes!

Delivery Service

Our logistics teams are dedicated to providing expert service for all regions. We strive to maintain long-term relationships with shipping lines and agents.

Frequently Asked Questions

If your question is not listed, please contact us.

Unlike standard rubber, which swells, softens, and loses its grip when exposed to oils, greases, or drilling fluids, our PU anti-slip mats and seals maintain their structural integrity and “bite,” ensuring long-term safety and performance.

We offer a versatile range from 20 Shore A (soft and flexible) to 98 Shore A (extremely hard and rigid). For example, we typically recommend a softer Shore 70A-80A for skirting to ensure a tight seal, while PU wheels often require a harder 90A-95A for maximum load capacity.

Yes, we can produce PU in any color (Pantone/RAL). In the industry, colors are often used for identification: for example, we can use different colors to help your maintenance team quickly distinguish between “Standard Grade,” “High-Temp,” and “Chemical Resistant” scraper blades at a glance.

Bonding failure is a common issue with cheap PU. We use a proprietary multi-stage chemical bonding process including grit-blasting, specialized primers, and controlled thermal curing. This ensures the bond between the PU and the metal core is often stronger than the polyurethane itself.

Yes. Our PU is engineered to remain flexible and effective in temperatures ranging from -40°C to +80°C. For high-heat applications, we offer specialized formulations that can withstand continuous exposure up to 100°C without losing their mechanical properties.

Absolutely. Our impact bars feature a top layer of low-friction UHMW-PE and a thick core of high-impact polyurethane. This PU core acts as a massive shock absorber, dissipating the kinetic energy of falling materials that would otherwise pierce a belt supported only by rigid steel idlers.