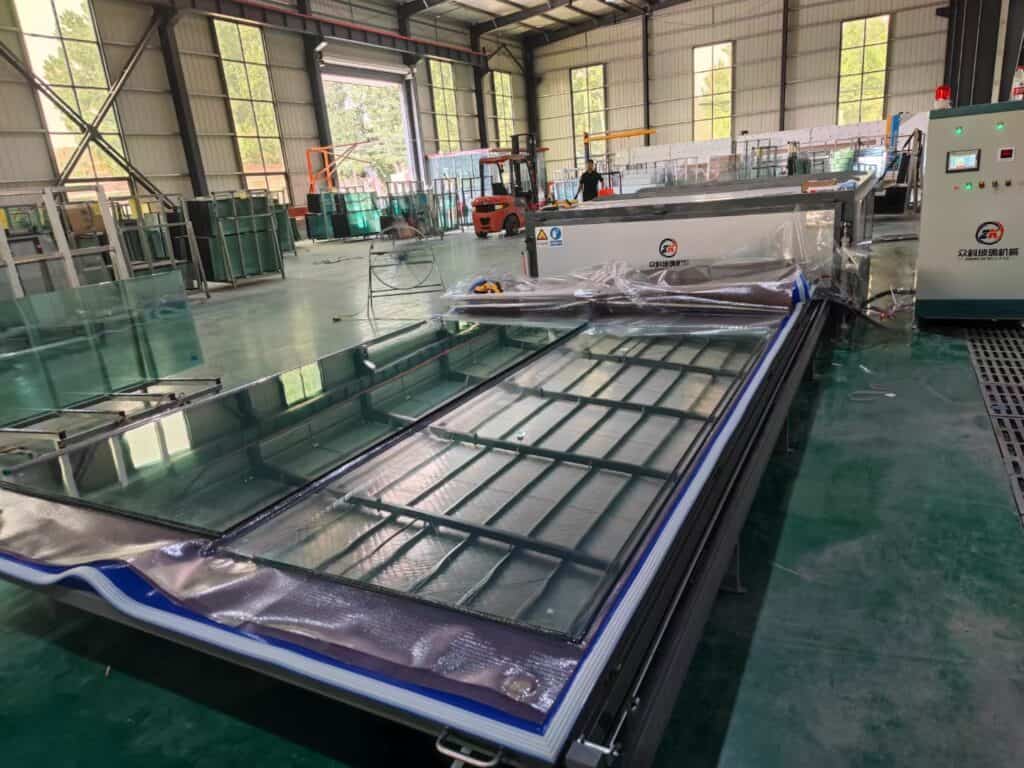

Silicone Vacuum Bag for Glass Lamination Machine Manufacturer

Reusable Silicone Vacuum Seal Bags Supplier

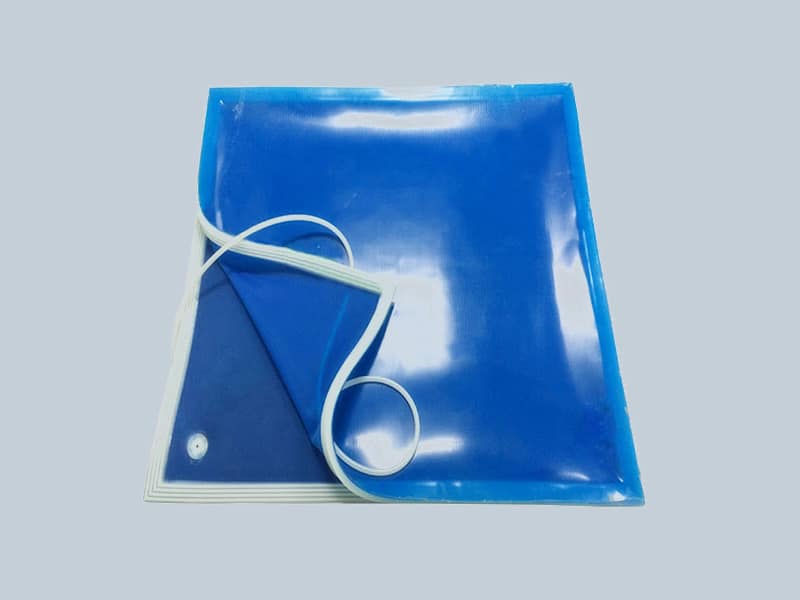

Silicone vacuum bags are critical consumables used in EVA glass lamination processes. A high-quality reusable silicone vacuum bag helps remove trapped air, stabilize the lamination stack, and significantly reduce defects such as bubbles, delamination, and edge leakage.

Suconvey supplies reusable silicone vacuum bags for glass lamination machines, designed for high-temperature cycling, repeated use, and stable vacuum sealing.

Our vacuum bags are widely used in architectural laminated glass, safety glass, decorative glass, and industrial glass lamination lines.

High Temperature Resistant silicone vacuum bag

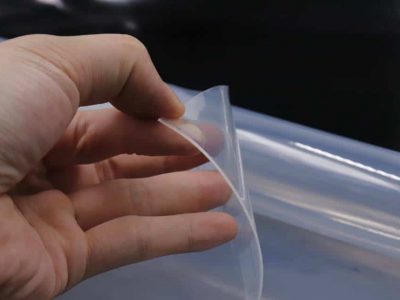

A silicone vacuum bag is a flexible, airtight silicone rubber envelope used to enclose glass sheets and interlayers during lamination. By applying vacuum pressure, the bag removes air between layers and ensures uniform contact during heating and pressing.

Compared with disposable vacuum films, reusable silicone vacuum bags offer:

longer service life

more stable vacuum performance

lower long-term operating cost

consistent lamination quality

Product Details

High Tear Strength Silicone Rubber Vacuum Bag Supplier

Key Features

High tear strength silicone rubber for repeated handling and loading

Excellent temperature resistance for EVA lamination heating cycles

Stable sealing edges to maintain vacuum throughout the process

Smooth and controlled surface finish to minimize imprint risk

Reusable design for cost-effective long-term operation

Custom sizing available for different lamination machines

China Custom Silicone Vacuum Bag Manufacturer

Technical Specifications

| Item | Typical Data | Notes |

|---|---|---|

| Product | Reusable Silicone Vacuum Bag | For glass lamination machines |

| Material | Silicone Rubber | Upgraded compounds available |

| Temperature Resistance | -40℃ to 260℃ | Typical EVA lamination range |

| Surface Finish | Smooth / Matte / Wave | Custom pattern available |

| Key Performance | Tear resistance, vacuum sealing | Selected by production frequency |

| Customization | Size, thickness, surface | Provide drawing or machine model |

Why Silicone Vacuum Bags Matter in Glass Lamination

Vacuum bag quality has a direct impact on yield rate and production efficiency. Poor-quality bags often lead to:

unstable vacuum and air leakage

bubble formation inside laminated glass

surface imprinting and optical defects

frequent bag replacement and downtime

Our silicone vacuum bags are engineered to maintain stable sealing performance and tear resistance, even under demanding lamination cycles.

Types of Silicone Vacuum Bags We Supply

Standard Reusable Silicone Vacuum Bag

Designed for routine EVA glass lamination with balanced durability and flexibility.

High Tear Strength Vacuum Bag

Recommended for large-format glass or high-frequency production lines.

High Temperature Resistant Vacuum Bag

For applications with higher lamination temperatures or longer heat-holding cycles.

Custom Silicone Vacuum Bag

Manufactured according to machine model, drawing, or specific lamination requirements, including custom thickness, surface finish, and sealing structure.

Typical Applications

Silicone vacuum bags are widely used in:

EVA laminated safety glass

Architectural laminated glass panels

Decorative laminated glass

Solar and special laminated glass

Industrial flat glass lamination

If your application has special requirements such as large glass size, frequent cycling, or strict surface quality, our engineers can recommend a suitable vacuum bag structure.

Customization Options

We offer extensive customization to match different lamination systems:

Bag size: made to machine dimensions or drawings

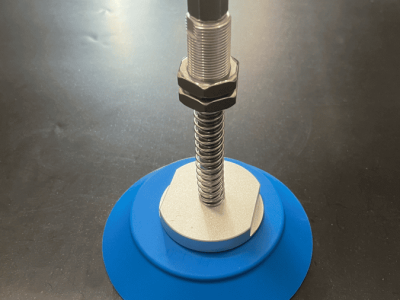

Valve: Stainless Steel, Aluminum or silicone

Surface finish: smooth, matte, wave, or custom pattern

Color: translucent or customized

Material grade: standard or upgraded silicone compounds

How to Choose the Right Silicone Vacuum Bag

To select the most suitable vacuum bag, please consider:

Maximum glass size and thickness

Heating temperature and cycle time

Frequency of daily production cycles

Vacuum stability requirements

Lamination machine model

Providing this information helps us recommend a durable and cost-effective solution.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

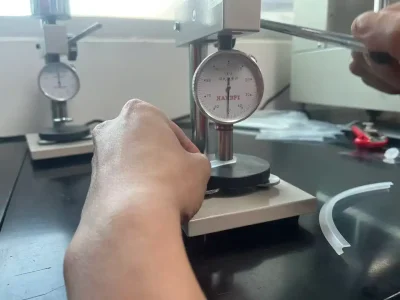

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone bags in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test bags can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

A silicone vacuum bag is used in EVA glass lamination to remove trapped air between glass and interlayers, ensuring uniform pressure and preventing bubbles or delamination.

Service life depends on lamination temperature, cycle frequency, and handling. Under normal conditions, a high-quality silicone vacuum bag can be reused for many cycles before replacement.

Typical silicone vacuum bags can handle temperatures up to 260°C. For higher or prolonged temperature exposure, special silicone compounds can be used.

Vacuum bag size should match your lamination machine and maximum glass dimensions. Providing machine model or drawings helps ensure proper fit.

Common causes include poor sealing edges, material aging, surface damage, or improper bag size. Using a properly designed silicone vacuum bag reduces these risks.

Yes. We provide custom silicone vacuum bags based on drawings, samples, or machine specifications, including size, thickness, and surface finish.