Silicone Rubber Sheet Rolls Manufacturer

Our Silicone Sheets – Available in Multiple Grades and Custom Options

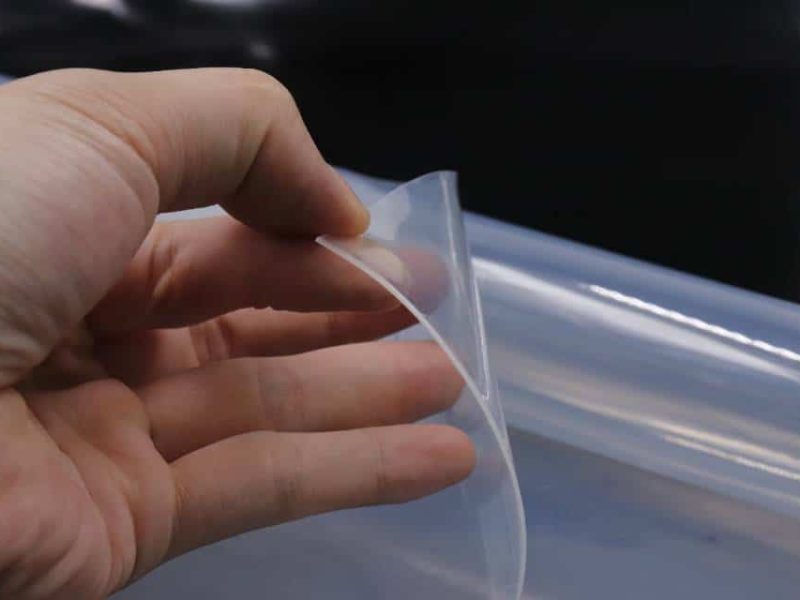

Type 1: Solid Silicone Sheet

Our Solid Silicone Sheets are highly durable, flexible, and offer superior abrasion resistance, making them ideal for sealing, gaskets, and industrial applications. Up to 300°C. Hardness Range: 5-85 Shore A. Thickness: 1mm – 50mm (customizable)

FDA/LFGB, Non-toxic and odorless. Certified for direct food contact and processing lines.

Applications:

- Food processing and handling equipment

- Gaskets and seals for food storage containers

- Medical-grade silicone pads

Biocompatible and peroxide-free. Engineered for healthcare devices and laboratory use.

Applications:

- Medical device seals and gaskets

- Laboratory equipment insulation

- Sterilization trays and packaging materials

Ultra-Pure: Elimination of peroxide by-products ensures maximum clarity and no yellowing over time.

Applications:

- Medical and pharmaceutical sealing

- Food processing machinery components

- Cleanroom environments

Stabilized to withstand continuous exposure up to +300°C (572°F) without losing elasticity.

Applications:

- Industrial machinery seals

- High-temperature insulation materials

- Automotive engine parts

Superior light transmission for display protection and optical sealing applications.

Applications:

- Insulation material in small electronic components

- Custom seals and gaskets

- Medical testing equipment.

Precision-calendered down to 0.1mm for electronic insulation and sensitive diaphragms.

Applications:

- Screen protective covers and light diffusers

- LED enclosures and light guides

- Medical applications requiring high visibility and biocompatibility

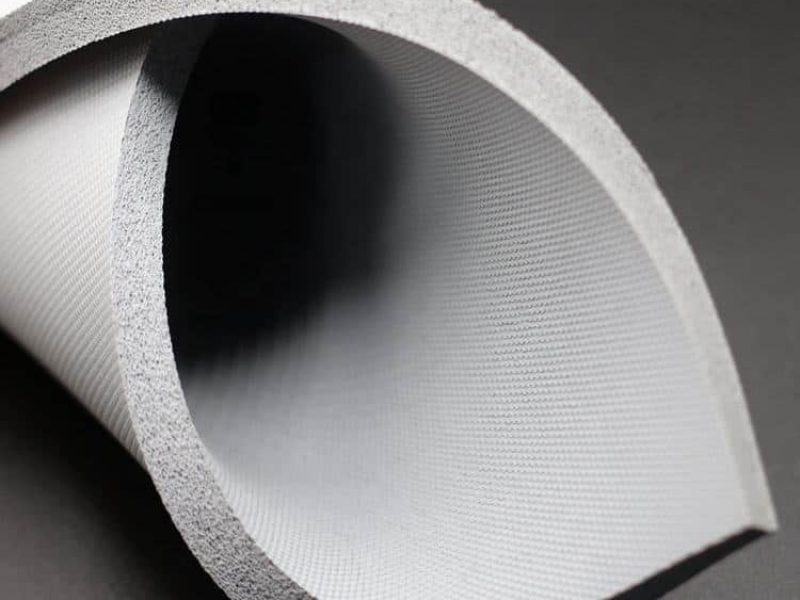

Embedded fabric core provides zero-stretch dimensional stability for high-pressure gaskets.

Applications:

- Silicone Rubber Membrane For Solar Modules Lamination

- Machines and engines exposed to high friction and mechanical stress.

- Insulation in electrical devices that need reinforced structural strength

FVMQ: Superior resistance to fuels, oils, and solvents. The gold standard for aerospace and automotive seals.

Applications:

- Fuel system seals and gaskets exposed to aviation fuel

- Seals in engines, fuel lines, and transmission systems

- Highly abrasive environments requiring chemical resistance

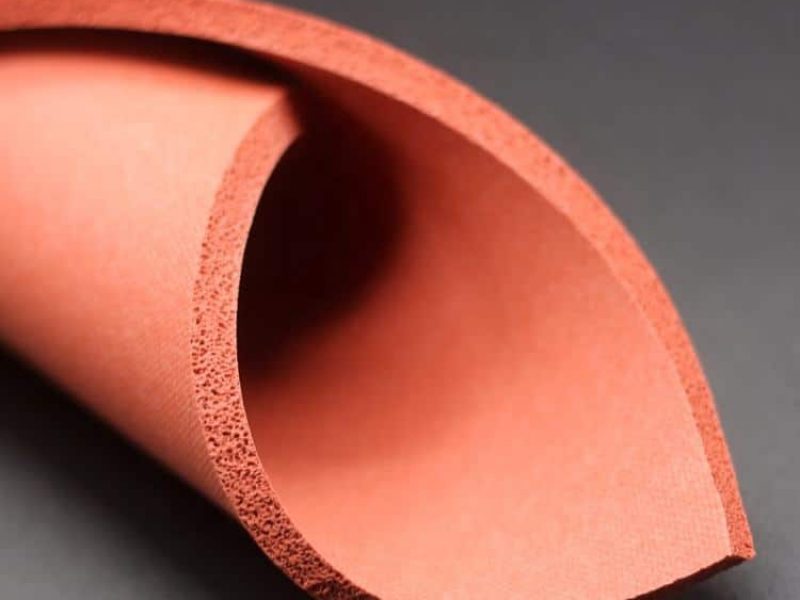

Type 2: Silicone Foam Sheet

Closed-cell structure for superior vibration damping, thermal insulation, and low-compression sealing. Density: 0.20 – 0.60 g/cm³.

Available with 3M™ or custom adhesives for simplified peel-and-stick installation.

Stabilized to withstand continuous exposure up to +220°C without losing elasticity.

UL94-V0: Self-extinguishing properties for critical safety in EV batteries and public transport.

We can customize the dimensions, hardness, density, and color of silicone sheet according to your requirements.

Technical Datasheet---Silicone Rubber (VMQ) Sheet

Suconvey is a leading manufacturer and supplier of high‑quality silicone sheets, designed to meet the needs of various industries including automotive, food processing, medical devices, and electronics. Our silicone sheets are available in a wide range of thicknesses, hardness, and sizes, with customizable options to suit your specific application needs.

Premium silicone sheet rolls & custom silicone sheeting manufactured for industrial, food, medical, and aerospace applications. FDA & UL94 certified silicone sheets in multiple grades and customizable specifications.

Item | Data | Item | Data |

Thickness | 0.1mm~20mm | Width | 1mm~3500mm |

Length | Custom | Specific Gravity | 0.2g/cm3~1.3g/cm3 |

Color | Pantone Card and transparent | Hardness | 5~90 Shore A |

Appearance | Smooth/Wave/Matte | Temperature | -60℃-300℃ |

Tear Strength | Up to 25 Mpa | Elongation | 300-650% |

Deformation Rate | ≤9% | Anti-Flammable | UL 94 – V0 |

Acid and Alkali Resistance | Available | Insert Layer | Fabric or Canvas |

Stick Layer | 3M or Brush Glue | Food Grade | FDA Approved |

Medicine | Passed Halogen Test | Water Absorption | 0% for silicone, 80% for sponge |

Aging Teriod | 3 years under right environment | Chemical Safe | ROHS and SVHC certificate |

Why Choose Silicone Sheets?

Silicone is an advanced synthetic elastomer known for its superior thermal stability, chemical resistance, and flexibility. Ideal for both high-temperature and low-temperature environments, silicone offers excellent performance in applications requiring durability, non-toxicity, and high performance.

Key Benefits of Silicone Sheets:

- Temperature Resistance: Works in environments from −60°C to +250°C, ideal for both extreme heat and cold applications.

- Chemical Resistance: Silicone resists oils, solvents, ozone, UV radiation, and many other aggressive chemicals, making it ideal for industrial use.

- Food-Grade and Medical-Grade Options: FDA and LFGB compliant, perfect for food processing, medical devices, and laboratory applications.

- Durability: Outstanding abrasion resistance and compression set (ability to retain shape after compression), offering long-lasting performance.

High Quality Silicone Rubber Sheet For Sale

- Custom Formulations: We don’t just sell sheets; we engineer compounds. Need specific color matching or Shore A hardness? We can customize it.

- Precision Cutting Service: State-of-the-art CNC and water-jet cutting to deliver finished gaskets directly from your CAD files.

- Quality Assurance: Every batch undergoes rigorous testing for tensile strength, elongation, and compression set before dispatch.

- Global Logistics: Optimized supply chain ensuring competitive shipping rates and lead times to North America, Europe, and SE Asia.

Production Capabilities

- 12+ Advanced Production Lines: Equipped with high-precision calendering and extruding machines for consistent thickness.

- 5,000m² Manufacturing Hub: A large-scale facility dedicated to Silicone, Polyurethane, and Rubber production.

- Custom Compounding: We mix our own raw materials in-house, allowing us to customize Shore Hardness, Color, and chemical resistance to your exact specs.

- Precision Secondary Processing: In-house CNC cutting, die-cutting, and PSA (Adhesive) application for “ready-to-use” components.

Your Trusted Silicone Sheet Rolls Supplier in China

- Raw Material Validation: Every batch of raw silicone or rubber is tested for purity before entering the production line.

- Precision Compounding: Digital control of material mixing to ensure batch-to-batch consistency.

- In-Line Monitoring: Real-time laser sensors monitor sheet thickness and surface uniformity during calendering.

- Secondary Vulcanization: Extended post-curing to eliminate volatiles and ensure material stability (critical for Medical/Food grade).

- Laboratory Testing: Physical property testing including Tensile Strength, Elongation at Break, and Compression Set.

- Final Inspection & COA: A final 100% visual check. Every shipment is accompanied by a Certificate of Analysis (COA).

Wholesale Best Silicone Rubber Sheet

- Inventory Safety Stock: We maintain a 2,000-meter buffer of standard sheets for immediate dispatch.

- Prototyping in 5-7 Days: Rapid sampling to accelerate your project timeline.

- Secure Industrial Packaging: Every roll is wrapped in protective moisture-proof film and secured in reinforced crates to ensure zero damage during international transit.

SUCONVEY Service

With over 11 years of experience in the rubber industry, we possess a wealth of expertise. SUCONVEY is dedicated to solving the rubber challenges faced by industries worldwide.

Frequently Asked Questions

If your question is not listed, please contact us.

The choice depends on your application’s requirements for compression and durability. Solid silicone offers high tensile strength and excellent tear resistance, making it ideal for precision gaskets and mechanical seals. Silicone foam (or sponge) is preferred for vibration damping, thermal insulation, and applications requiring a soft, compressible seal with low closure force.

Platinum-cured silicone is higher purity, non-yellowing, and peroxide-free, making it the standard for food (FDA) and medical (USP Class VI) applications. It also offers better clarity and elongation. Peroxide-cured silicone is a more cost-effective solution for general industrial sealing where high purity and extreme clarity are not critical.

Yes. Standard industrial silicone sheets operate reliably from -60°C to +230°C (-76°F to +446°F). For extreme environments, we offer High-Temperature Resistant formulations that can withstand continuous exposure up to +300°C (572°F) while maintaining structural integrity and elasticity.

Absolutely. We provide FDA-grade silicone sheeting that meets 21 CFR 177.2600 standards for food contact. Additionally, all our silicone materials are RoHS and REACH compliant, ensuring they are free from hazardous substances and safe for global distribution in the electronics and automotive sectors.

Yes, we specialize in customization. We can provide silicone sheets in thicknesses from 0.1mm to 50mm and widths up to 3500mm. We also offer professional Self-Adhesive Backing (PSA) using premium 3M™ or specialty industrial adhesives for easy “peel-and-stick” installation on various surfaces.

For standard stock items, we ship within 24-48 hours. For custom colors, specific Shore A hardness, or unique formulations, our typical lead time is 10-12 business days. We also offer rapid prototyping for engineers who need samples in as little as 5-7 days.