Custom Silicone Products Manufacturer

Various of Customize Silicone Rubber Products Types

High Quality Custom Silicone Products Supplier

Custom Silicone Cooking, Baking Tableware Tools

Elevate food safety and cooking performance. We manufacture custom spatulas, mats, and brushes using 100% food-grade silicone that is BPA-free and heat-resistant.

Key Features: Non-stick, dishwasher safe, and durable.

Custom Silicone Bellow Dust, Cover

Precision-engineered flexible joints designed to protect moving machinery from dust, moisture, and debris.

Designed for dynamic protection of mechanical joints and sensitive equipment.

Key Features: High Flexibility, Hermetic Sealing, Extreme Resilience

Custom Silicone keymats and Buttons

Precision-molded interfaces for consumer electronics and industrial controls.

- Key Features: Tactile Feedback, Durability, Custom Graphics

Custom Silicone Mold For Chocolate, Soap, ice

High-detail custom molds for the confectionery industry. Our molds offer excellent flexibility for easy release while maintaining intricate design details.

Key Features: Flexible, reusable, and oven/freezer safe.

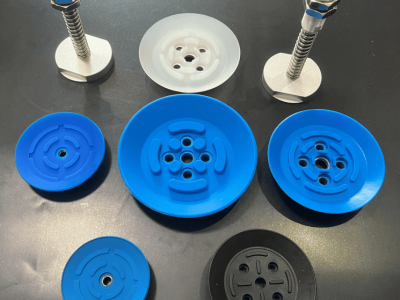

Custom Silicone Stoppers, Plugs & Caps

Protect your equipment with precision-engineered rubber stoppers. We provide custom-sized plugs for powder coating, chemical labs, and industrial sealing applications.

Key Features: Chemical resistant, high-temperature stability, and perfect fit.

Custom Silicone Protective Sleeves & Cases

Impact-resistant covers for handheld devices, glass bottles, and delicate industrial instruments.

- Key Features: Impact Absorption, Anti-Slip Texture, Perfect Fit

Custom Silicone Figures & Toys

High-detail molded characters for branding, premiums, and children’s products.

Key Features: Intricate Detailing, Skin-Safe Material, Soft-Touch Finish

Technical Datasheet

Item | Data | Item | Data |

Design | As drawing or sample | Specific Gravity | 0.9g/cm3~1.3g/cm3 |

Color | Pantone Card and transparent | Hardness | 20~90 Shore A |

Appearance | Smooth/Wave/Braided | Temperature | -60℃-350℃ |

Tear Strength | Up to 25 Mpa | Elongation | 300-650% |

Deformation Rate | ≤9% | Anti-Flammable | FRAS approved |

Acid and Alkali Resistance | Available | Insert Layer | Fabric or Canvas |

Stick Layer | 3M or Brush Glue | Food Grade | FDA Approved |

Medicine | Passed Halogen Test | Water Absorption | 0% for silicone, 80% for sponge |

Aging Teriod | 5 years under right environment | Chemical Safe | ROHS and SVHC certificate |

Customize Silicone Rubber Products Manufacturer

We don’t just use standard silicone; we engineer the material to fit your specific environment.

- 100% Virgin Silicone: We never use recycled fillers. Our materials are fully compliant with FDA, LFGB, RoHS, and REACH.

- Functional Formulas: We can customize silicone properties, including High-Tear Strength, Flame Retardancy (UL94-V0), Anti-static, and Extreme Temperature Resistance (-60°C to +260°C).

- Safety First: Available in Medical-grade, Food-grade, and Industrial-grade formulations.

- Full Customization: Bespoke hardness (10-80 Shore A), any Pantone color, and specialized surface textures.

In-House Mold Design & Engineering

Unlike many suppliers who outsource tooling, we operate an in-house CNC mold-making department.

- Precision: We maintain tight tolerances (up to ±0.05mm) to ensure your custom parts fit perfectly every time.

- Speed: By controlling the tooling process, we reduce lead times for custom molds by 30-40%.

- DFM Support: Our engineers provide a free Design for Manufacturing (DFM) review to optimize your part for cost-effective mass production.

Your Trusted Custom Silicone Products Supplier

Quality is not just a promise; it is a documented process at Suconvey.

- ISO 9001:2015 Certified: Our production follows international quality management standards.

- Multi-Stage Inspection: From incoming raw material testing to 100% visual inspection and batch hardness testing, we ensure zero-defect shipments.

- Traceability: Every batch comes with a material certificate and test report, ensuring full accountability for your supply chain.

From Blueprint to Mass Production

Our workflow is designed for transparency and reliability:

- RFQ & Design Review: We analyze your 3D drawings (Step/IGS/CAD) within 24 hours.

- Prototyping: Rapid sample creation using 3D printing or trial molds to validate the concept.

- Tooling & Vulcanization: Precision mold fabrication followed by high-temperature vulcanization.

- Finishing & QC: Trimming, secondary curing (if needed), and strict quality checks.

- Global Delivery: Protective packaging and reliable logistics to your warehouse.

SUCONVEY Service

With over 11 years of experience in the rubber industry, we possess a wealth of expertise. SUCONVEY is dedicated to solving the rubber challenges faced by industries worldwide.

Frequently Asked Questions

If your question is not listed, please contact us.

We prefer 3D CAD files in STEP (.stp), or SolidWorks (.sldprt) formats for precise mold making. We can also work from 2D drawings (PDF, DWG) or physical samples. If you only have a concept, our engineering team can provide Design for Manufacturing (DFM) support to create the necessary blueprints.

Mold costs depend on the part complexity, size, and the number of cavities. At Suconvey, we operate our own in-house CNC mold shop, which allows us to offer highly competitive tooling prices. For large-volume orders, we often offer mold-fee rebates once a certain production quantity is reached.

Yes. We offer two options for prototyping: 3D printing (for fitment and aesthetic checks) and trial molds (using actual silicone material to test functional performance). Trial molds are recommended if you need to test the specific hardness or heat resistance of the part.

Absolutely. We can match any Pantone Color Number or a physical color sample you provide. We also offer various finishes, including matte, glossy, translucent, or even glow-in-the-dark effects.

Yes. We maintain a strict supply chain for raw materials. Our food-grade silicone is FDA and LFGB compliant, and we also provide medical-grade silicone (USP Class VI) for healthcare applications. All products are guaranteed BPA-free, lead-free, and phthalate-free.

Yes, we specialize in overmolding and silicone-to-metal bonding. This process creates a permanent, high-strength bond between the silicone and the insert (such as stainless steel, brass, or high-temp plastics), which is essential for products like industrial bellows or reinforced handles.

Quality is controlled at every stage:

- Material Inspection: Verification of silicone batch properties.

- In-Process QC: Hourly checks of dimensions and hardness during molding.

- Post-Curing: Ensures full stability and removes volatiles.

- Final Inspection: 100% visual check for flashes, bubbles, or surface defects before packaging.

Yes. Delamination usually occurs because the metal wasn’t properly pre-treated or the wrong primer was used. We use a sandblasting/degreasing process followed by high-performance bonding agents tailored to the specific metal. Our silicone-to-metal bonding is tested for pull-strength to ensure it never separates under industrial loads.

Silicone is naturally prone to static electricity. If your application requires a clean surface, we can apply a specialized Anti-static Oil Spray (Hand-feel Coating). This creates a smooth, silky finish that repels dust and lint, giving the product a premium feel.