Conveyor Belt Maintenance Products Manufacturer

Learn about the variety of conveyor maintenance that SUCONVEY services.

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

SUCONVEY Service

We are a Chinese supplier providing maintenance solutions and products for mining conveyor belts, including belt cleaners, impact beds, rubber skirts, vulcanizing machines, conveyor belts, rollers, and other products.

SUCONVEYYour Technical Partner in Rubber Manufacturing

As a supplier of conveyor belt system maintenance solutions, our advantage lies not only in “manufacturing” but also in our ability to “ensure continuous system operation and reduce downtime”. When you choose to cooperate with us, our advantages are as follows:

Expertise and Experience

Having served high-intensity operating environments such as coal mines, cement plants, ports, and power plants for a long time, it has accumulated a massive amount of field data and can accurately predict the wear patterns of maintenance parts caused by different materials.

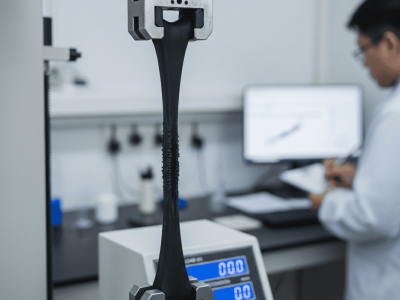

High quality raw materials

Made with highly elastic, wear-resistant modified rubber, it has an extremely low abrasion index (compliant with DIN/ISO standards), extending the replacement cycle.

Product Certificate

We have ISO 9001: 2015 Environmental Management Certificate. It has complete flame retardant and antistatic test reports to ensure absolute safety in flammable and explosive environments such as coal mines and grain storage facilities.

Customized services

For the renovation of existing conveyor systems, we provide on-site surveying services to ensure that every sweeper and every buffer strip can be seamlessly integrated with the existing support frame and belt model.

Quality Assurance

Each batch of products must pass Akron abrasion test, peel strength test and hardness test to ensure that every spare part delivered to the customer can withstand high-intensity impact and friction.

Comprehensive after-sales service

Our relationship with you does not end with successful product delivery. We have an entire after-sales team that will follow up with you to ensure our services and products exceed all your expectations.

Applications & Case Studies

Suconvey is your trusted provider in conveyor maintenance service. After years of dedicated work in the conveyor maintenance services industry, we have provided many clients with high-quality products based on their specific needs.

Belt Connector in USA

Belt cleaner in Vietnam

Rubber Skirting in Singapore

Vulcanizing Machine in Brazil

Vulcanizing Machine in Bangladesh

Belt Connector in Korea

More Than Just a Rubber Products Manufacturer

Customer Support

SUCONVEY customer specialists are devoted to providing flexible conveyor maintenance solutions for clients worldwide. Always keep you posted about the latest trend and technology. And we’re happy to give you a heads up for price changes!

Delivery Service

Our logistics teams are dedicated to providing expert service for all regions. We strive to maintain long-term relationships with shipping lines and agents.

Frequently Asked Questions

If your question is not listed, please contact us.

This is our customers’ biggest concern. Our scrapers maintain appropriate pressure through a constant-pressure spring adjustment system, and the scrapers are made of various materials (polyurethane or tungsten carbide alloy). Polyurethane scrapers have excellent toughness and self-lubricating properties, thoroughly scraping away residue while adhering to the belt like a protective layer without causing abnormal wear.

The cycle depends on the abrasiveness of the material and the operating speed. Because we use high-grade imported polyurethane raw materials, their wear resistance is 3-5 times higher than ordinary materials on the market. Under normal mining conditions, our scrapers typically have a service life of 12 months or more. We also provide blade wear limit markings for your predictive maintenance.

Rollers are point contact devices, which are easily damaged by impacts from large materials, causing belt tearing or roller failure. Our shock-absorbing bed provides surface contact support; the bottom layer of high-elasticity rubber absorbs over 90% of the impact energy. The top layer uses ultra-high molecular weight polyethylene (UHMW-PE), which has an extremely low coefficient of friction, protecting the belt from punctures and effectively preventing wrinkles in the material drop zone.

Absolutely not. We use hot vulcanization molding technology to firmly bond the UHMW-PE sheet, high-elasticity rubber, and aluminum alloy frame. Our peel strength test data far exceeds industry standards, ensuring that it will never delaminate or detach, even under extreme impact or high-frequency vibration environments.

We recommend a double-layer sealed spill prevention skirt. The inner layer provides the primary seal, preventing large pieces of material from leaking out; the outer layer uses a flexible design to fit the conveyor belt, forming a secondary sealing vacuum zone specifically designed to suppress the escape of fine dust. Combined with our quick-clamping slots, frequent adjustments are unnecessary after installation, and dust control efficiency can be improved by over 80%.

This is our core strength. We don’t just sell standard parts; we provide customized engineering solutions. Our technical team can provide on-site surveying or perform secondary development based on your drawings. All cleaner and buffer bed supports are telescopic or angle-adjustable, ensuring “zero modification” for direct installation.