Custom Co-Extrusion & Bi-Extrusion Silicone Hoses & Profiles

Co-Extrusion Silicone Products Manufacturer

Many industrial and OEM applications demand silicone tubing and profiles that go beyond single-layer, mono-material designs. When you need multiple functional layers, different durometers, or combined solid/foam structures within a single piece of tubing or profile, traditional extrusion usually falls short.

At Suconvey, we offer custom co-extrusion and bi-extrusion silicone hoses and profiles — combining two or more silicone materials into a single, integrated component that delivers multi-function performance with precise geometry.

Whether you need foam + solid, two colors, or multi-durometer sections, our manufacturing capability delivers exactly what your design calls for.

Bi-Extrusion Silicone Products

Co-extrusion and bi-extrusion are rubber processing techniques where multiple materials are extruded together through the same die to form a single component with distinct layers or sections:

Co-Extrusion

Two or more materials (e.g., foam silicone + solid silicone) are extruded side-by-side or concentrically, forming a profile where each material retains its individual function but is bonded together into one part.

Bi-Extrusion

This is a subset of co-extrusion, typically involving two materials, often with a continuous “core + skin” or “solid + foam” configuration.

These techniques allow you to integrate multiple material properties — for example:

✔ soft, compressible foam interior

✔ durable, tear-resistant solid exterior

✔ dual-color visual distinction

✔ stepped durometer transitions

✔ gasket + cushion in one piece

Product Details

Bi-Extrusion Silicone Hoses Supplier

Key Features

- FDA approved, non-toxic & inert – safe for food-contact transfer applications.

- High tear strength & easy to clean – suitable for frequent cleaning cycles.

- Wide operating temperature range – suitable for both cold and high-temperature processes.

- Excellent flexibility & resiliency – maintains performance under bending and repeated handling.

- Durable & dependable – built for production lines and long service life.

- UV / ozone & chemical resistance – good weathering resistance for challenging environments.

- Custom sizes available – diameter, thickness, color and hardness can be customized.

China Co-Extrusion Silicone Profiles Manufacturer

Technical Specifications

| Custom Co-Extrusion & Bi-Extrusion Silicone Hoses & Profiles | |

|---|---|

| Material | Silicone elastomer (solid, sponge/foam, custom durometer) |

| Structure | Co-extruded multi sections |

| Temperature Range | −60°C to +250°C (dependent on grade) |

| Hardness | Soft to firm (Shore A 10–90, variable) |

| Color | Custom two-color/multi-color available |

| Available Forms | Coils, cut-length, custom shapes |

| Compliance | RoHS, SVHC (others on request) |

| Typical Functions | Cushion + seal, indicator, support + vibration dampening |

Double-Row Multi-Cavity Silicone Tube Supplier

Material Structures We Support

We commonly supply profiles such as:

✔ Solid + Foam Co-Extrusion

✔ Dual Color Silicone Tubing

✔ Hard + Soft Durometer Hybrid Tubing

✔ Concentric Multifunction Tubes

✔ Strip + Insert Profiles

Common material combinations include:

| Section A | Section B | Function |

|---|---|---|

| Solid Silicone | Foam Silicone | Outer strength + inner cushion |

| Soft Silicone | Harder Silicone | Sealing + support |

| Red Silicone | Black Silicone | Color coding + identification |

| Smooth | Textured | Aesthetic + grip |

China Co-Extrusion Silicone Profiles Manufacturer

Double-Row Multi-Cavity Silicone Tube

When you inquire, a good starting point is to provide:

✔ desired outer profile geometry

✔ function of each section (e.g., support/cushion/seal/visual)

✔ typical operating temperature range

✔ media contact conditions (liquid, gas, steam, chemicals)

✔ expected mechanical load or compression

✔ color requirement (if any)

With these, we can help select the right material grades, durometers and co-extrusion structure.

Expanded Applications

Automotive & Transportation

- Dual-material sealing strips

- Cushion + gasket combination profiles

- Color coded fluid or air hose sections

- Engineers in mobility applications require components that endure vibration, thermal cycling, and assembly tolerances.

Medical & Laboratory Equipment

- Dual hardness tubing for pump dosing + cushioning

- Color differentiated fluid delivery lines

- Foam interior with sealing exterior for ergonomic handling

- Here, performance, cleanliness and material consistency are critical.

Industrial Automation & Robotics

- Multi-layer protective sleeves

- Hybrid shock absorber + protective cover

- Pneumatic lines with integrated mounting features

- Co-extrusion eliminates secondary parts and reduces maintenance points.

Consumer & Appliance Systems

- Wash-cycle resistant hoses

- Integrated gasket + trim pieces

- Color coded channels in multi-function hoses

- For complex assemblies, co-extrusion simplifies supply chain and installation.

Why Choose Suconvey?

Suconvey provides more than just tubing — we offer engineering support, quality assurance and tailored supply solutions to help your project succeed:

---Deep Material Expertise

- Over 10+ years specializing in silicone tubing and hose for industrial, food, beverage and pharmaceutical markets.

- Understand performance tradeoffs for tubing under temperature, pressure, flex cycles and hygiene requirements.

---Custom Design Support

- Size optimization for flow rates and installation space

- Material selection (solid vs sponge) based on media, pressure and cleaning methods

- Surface finish that supports CIP/SIP sanitation

- Wall thickness vs flexibility design for bend radius and abrasion resistance

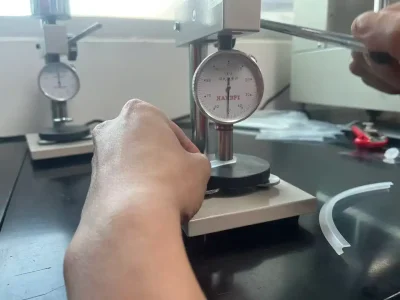

---Quality from Raw Material to Delivery

- Certified food-grade silicone (FDA) compounds

- Controlled extrusion to maintain tight tolerances

- In-house inspection for wall thickness, inner/outer diameter and surface quality

- Batch traceability for consistency and audit support

---Flexible MOQ & Sample Support

- Support small and pilot orders before production scaling

- Quick turn pre-production samples to verify fit and performance

- Customized packaging and labeling per project needs

---Global Supply & On-time Delivery

- Efficient logistic planning to keep your production on schedule

- Export packing optimized for protection, cleanliness and traceability

Why Customers Choose Custom Silicone Co-Extrusion?

When working with single-material tubes or strips, engineers often encounter limitations:

❌ single hardness limits performance

❌ difficult to unify sealing + cushion

❌ two separate parts increase assembly cost

❌ color coding requires painting or sleeves

Co-extruded / bi-extruded silicone components solve these issues directly in the part:

Multi-Function in One Component

- structural support

- soft sealing interface

- compressible shock absorption

- integrated color coding

- This reduces parts count, assembly time, and total system cost.

Tailored Durometer Engineering

Different sections of the same profile can have different hardness values (Shore A), enabling:

- firm support sections

- soft sealing or cushioning sections

- transition zones that flex without stress concentration

Improved Assembly Reliability

Because all sections are extruded together, there’s no need for secondary bonding or adhesives — eliminating a common failure point.

Visual & Functional Differentiation

Dual/multi-color profiles help technicians quickly identify parts or fluid paths, which is especially valuable in complex assemblies or safety-critical applications.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone tubes are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test tubes can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Related Products

Frequently Asked Questions

If your question is not listed, please contact us.

Co-extrusion generally refers to extruding multiple materials together through a single die to form a multi-section part. Bi-extrusion specifically means two materials joined in one profile. Both techniques integrate functions into a single component.

We recommend specifying the function of each section first (e.g., sealing, support, cushioning). Our engineers then suggest appropriate Shore A values that meet those needs.

Yes. We can supply cut-to-length pieces, coils or pre-assembled parts that are ready to integrate into your production line.

Absolutely — multi-color profiles are often used for visual identification, fluid path distinction, or branding requirements.

Yes — we can supply RoHS, SVHC declarations and, upon request, other test reports or compliance documents depending on your industry.

MOQ: Flexible, often low quantity support to help prototyping or small runs

Sample Lead Time: 1–3 business days for standard sizes

Production Lead Time: Depends on size and order volume, typically 1–3 weeks