Platinum Cured Silicone Tubes — Durable, Clean & High-Performance

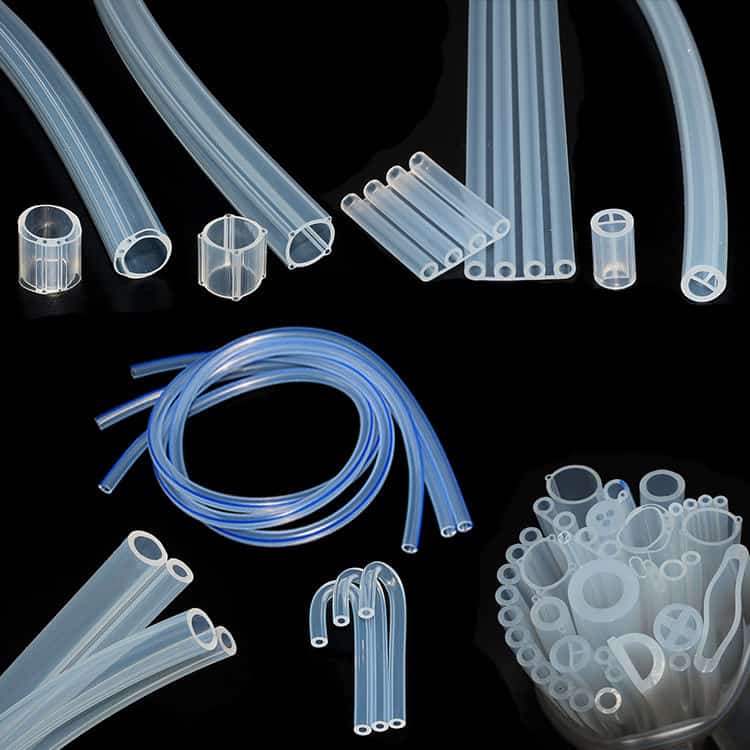

Platinum Cured Silicone Rubber Tubes Manufacturer

Platinum cured silicone rubber tubing is widely recognized by engineers and buyers as a premium silicone solution for applications demanding high purity, superior mechanical stability and long service life.

Compared to cheaper peroxide-cured alternatives, platinum cured (also called addition cured) silicone offers cleaner cross-linking, fewer residual by-products and markedly improved performance — especially where reliability counts.

At Suconvey, we manufacture platinum cured silicone tubes with consistent dimensions, excellent flexibility and strong long-term resilience, making them ideal for industries such as medical, pharmaceutical, food & beverage, analytical equipment and automation systems.

What Differentiates Platinum Cured Silicone Tubing?

Most people who compare silicone materials quickly identify a few key advantages, but the real difference is in how it performs in service:

Clean Curing — Zero Halogen & Minimal By-Products: Platinum cured silicone cures via an addition reaction, leaving very low ionic residues, minimal odor and no peroxide fragmentation compounds.

Stable Mechanical Properties Over Time

Unlike sulfur or peroxide cured elastomers that can age and become brittle, platinum cured silicone:

- Remains flexible after many thermal cycles

- Maintains dimensional stability under compression

- Has less tendency to harden or crack over months or years

Superior Chemical & Temperature Resistance

- repeated sterilization

- extreme heat and cold

- exposure to cleaning agents and steam

Without losing elasticity or structural integrity. That’s why it’s a top choice for both autoclave applications and industrial fluid systems.

Product Details

Platinum Cured Silicone Hoses Supplier

Key Features

- FDA approved, non-toxic & inert – safe for food-contact transfer applications.

- High tear strength & easy to clean – suitable for frequent cleaning cycles.

- Wide operating temperature range – suitable for both cold and high-temperature processes.

- Excellent flexibility & resiliency – maintains performance under bending and repeated handling.

- Durable & dependable – built for production lines and long service life.

- UV / ozone & chemical resistance – good weathering resistance for challenging environments.

- Custom sizes available – diameter, thickness, color and hardness can be customized.

China Platinum Cured Silicone Tubes Manufacturer

Technical Specifications

| Platinum Cured Silicone Tubing – Typical Specifications | |

|---|---|

| Material | Platinum cured addition-type silicone rubber |

| Inner Diameter (ID) | 1 mm – 150 mm (custom available) |

| Outer Diameter (OD) | 2 mm – 170 mm |

| Wall Thickness | 0.5 mm – 12 mm |

| Hardness (Shore A) | 20 – 90 |

| Temperature Range | −60°C to +250°C |

| Resistance | Ozone, UV, steam, CIP chemicals |

| Purity | Low extractables; minimal by-products |

| Compliance | FDA/USP on request |

| Available Forms | Coils, cut lengths, OEM packaging |

Expanded Applications

Medical & Healthcare Equipment

If you’re designing or maintaining equipment that contacts biological fluids, reagents or patient connected lines, you care about:

- Biocompatibility

- Low extractables

- Sterilization stability

Pharmaceutical & Bioprocess

In pharmaceutical manufacturing, tubing is part of the process loop, and contamination risk is unacceptable. Here platinum cured silicone helps with:

- aseptic transfers

- media and buffer lines

- sampling and waste lines

Food & Beverage Processing

In systems with heated transfer, cleaning cycles and sanitary demands, platinum cured silicone tubing allows:

- Repeated CIP/SIP cleaning

- Non-flavor-leaching fluid transfer

- Long-term service life

Instrumentation & Automation Systems

Sensors, actuators and machine tools often use silicone tubing for:

- Pneumatic control lines

- Signal protection jackets

- Cable harness insulation

Why Choose Suconvey?

Suconvey provides more than just tubing — we offer engineering support, quality assurance and tailored supply solutions to help your project succeed:

---Deep Material Expertise

- Over 10+ years specializing in silicone tubing and hose for industrial, food, beverage and pharmaceutical markets.

- Understand performance tradeoffs for tubing under temperature, pressure, flex cycles and hygiene requirements.

---Quality from Raw Material to Delivery

- Certified food-grade silicone (FDA) compounds

- Controlled extrusion to maintain tight tolerances

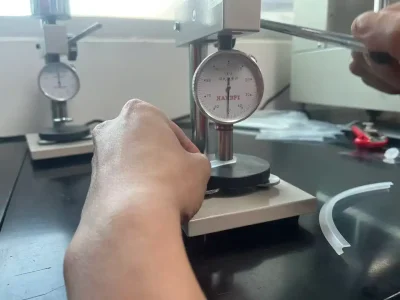

- In-house inspection for wall thickness, inner/outer diameter and surface quality

- Batch traceability for consistency and audit support

---Flexible MOQ & Sample Support

- Support small and pilot orders before production scaling

- Quick turn pre-production samples to verify fit and performance

- Customized packaging and labeling per project needs

---Global Supply & On-time Delivery

- Efficient logistic planning to keep your production on schedule

- Export packing optimized for protection, cleanliness and traceability

How to Select the Right Platinum Cured Silicone Tube

Choosing the correct tubing requires understanding your application environment:

1. Inner & Outer Diameter

Start with the actual component or cable diameter you are protecting or enclosing. A snug pre-shrink fit ensures optimal performance after installation.

2. Wall Thickness

Thicker walls provide better mechanical protection and insulation, but also cost more. Use the thinnest wall that still meets your strength and electrical requirements.

3. Temperature & Sterilization

Consider not just the operating temperature, but also the temperatures encountered during cleaning/sterilization cycles.

Typical platinum cured silicone tubing supports −60°C to +250°C service, with exceptional recovery.

4. Compliance Requirements

If you need FDA, USP, ISO-10993 or food-grade compliance, specify these up front so the material formulation meets your standards.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone tubes are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test tubes can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Related Products

Frequently Asked Questions

If your question is not listed, please contact us.

Platinum cured silicone cross-links via addition chemistry, producing fewer by-products and more stable mechanical and chemical properties than peroxide cured systems.

Yes — when specified with appropriate compliance (e.g., FDA/USP), it is widely used in medical fluid paths and diagnostic equipment.

Platinum cured silicone remains elastic and functional over a very wide range, which helps protect wiring or fluid lines even in systems subject to thermal cycling.

Yes — we routinely supply custom ID/OD and wall thicknesses to fit specific fixtures or assemblies, as well as color options for identification.

Material certificates, FDA/USP compliance statements and batch traceability details are available upon request for qualifying programs.