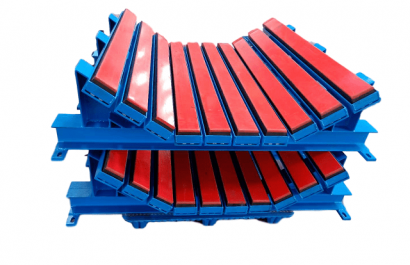

Polyurethane Conveyor Cleaner

We are wear abrasive polyurethane belt cleaner blades manufacturer in China. Belt cleaners are devices that are used to clean conveyor belts. They are usually mounted on the underside of the belt and have a scraping action that removes material from the belt as it passes. Belt cleaners are necessary because they prevent material from building up on the belt and causing problems such as belt tracking issues or jams. In some cases, they can also help to extend the life of the conveyor belt by preventing wear.

conveyor belt Scrapers & Blades mANUFACTURER

Key Features

- Application: Belt Width 650mm, 800mm, 1000mm, 1200mm, 1400mm, 1600mm, 1800mm, 2000mm, 2200mm

- Wear abrasive Polyurethane material

- Temperature from -20 to 120°C available

- Blade is detachable

- Wide range of colors available

- Extremely durable

- Used in power plants, mining, port, cement plant, food factory

Our service

- Cut to size

- On-time Dispatch Guarantee

- Supply free samples and design drawing

- Customize the size, thickness, color, hardness as you need

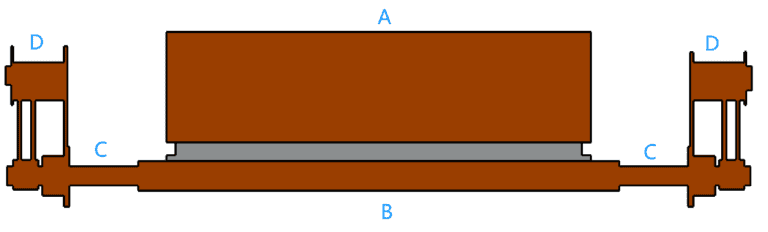

Conveyor Belt Width | A | B | C | D |

Belt Width 650mm | 600mm | 650mm | 700mm | 1 pc |

Belt Width 800mm | 762mm | 800mm | 700mm | 1 pc |

Belt Width 1000mm | 914mm | 1000mm | 700mm | 1 pc |

Belt Width 1200mm | 1067mm | 1200mm | 700mm | 2 pcs |

Belt Width 1400mm | 1321mm | 1400mm | 700mm | 2 pcs |

Belt Width 1600mm | 1524mm | 1600mm | 700mm | 2 pcs |

Belt Width 1800mm | 1676mm | 1800mm | 700mm | 2 pcs |

Belt Width 2000mm | 1828mm | 2000mm | 700mm | 2 pcs |

Belt Width 2200mm | 1912mm | 2200mm | 700mm | 2 pcs |

Polyurethane Material Datasheet | |||

Specification | Polyurethane Type | The largest belt speed fpm | 4.6m/s, 6m/s, 7.8m/s |

Application temperature | Continuous:-30–70°C | Roller diameter in. | 300-600mm/500-1000mm/800-1500mm |

Hardness | 85±2 Shore A | Tensile strength | 53 |

Elongation break | 614 | Tear strength | 108 |

Deformation rate in 23h | 30 | Springback | 20 |

High Quality conveyor belt cleaner Factory

As a belt cleaner manufacturer, we often get asked how to choose the right belt cleaner for one’s needs. There are a few factors to consider when making your selection. The first is the type of conveyor belt you have. The second is the environment in which the conveyor belt operates. And the third is the budget you have for a new belt cleaner.

Types of Belt Cleaners:

> Light Duty belt cleaner

> Medium Duty belt cleaner

> Heavy Duty belt cleaner

> primary belt cleaner

> Secondary belt cleaner

> No Working belt cleaner

> dry wipe belt cleaner

> V plough belt cleaner

> I plough belt cleaner

> H type Alloy belt cleaner

> Adjustment belt cleaner

About Company

Professional custom Polyurethane products FACTORY

Suconvey is a professional silicone&PU rubber products manufacturer that chooses the highest quality raw materials from all over the world as our long time experience in this industry after comparing the materials from different countries and districts, we get rid of the materials with any bad feedback and products.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Mrs. Stephanie

- 86-13246961981

- [email protected]

Free Consultation

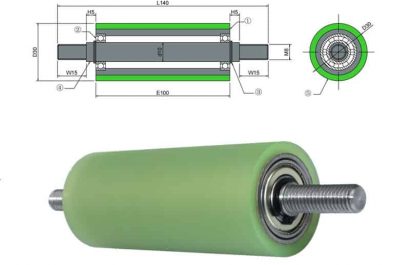

Urethane Parts for Conveyor System

We have developed a series of high quality, high performance Polyurethane rollers, Polyurethane wheels, Polyurethane rubber skirting, Polyurethane screen mats, Polyurethane Blades, Custom Urethane Products and so on. Polyurethane is a versatile material that can be used to manufacture products in a variety of ways. There are three main types of polyurethane parts: cast, extruded, and molded. Each type has its own unique benefits.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently asked questions

Here are the most frequently asked questions and answers about how to buy customized polyurethane products

A belt cleaner is a device that helps to keep a conveyor belt clean and free from debris. There are many benefits to using a belt cleaner, including:

- Reduced downtime: A clean conveyor belt will run more efficiently and reliably than a dirty one. This means less downtime for maintenance and repairs, and increased production time.

- Improved safety: A clean conveyor belt will reduce the risk of accidents and injuries. Debris on the belt can cause slipping and tripping, which can lead to serious injuries.

- Extended belt life: A clean conveyor belt will last longer than a dirty one, as debris can cause premature wear and tear. This means less money spent on replacements, and fewer disruptions to production.

- Enhanced product quality: Any contaminants on the conveyor belt can end up in the final product.

Belt cleaners are an essential part of any conveyor system. By keeping the belt clean, they help to prevent material build-up and carryback, which can lead to conveyor downtime and expensive repairs. Here are some tips on how to maintain your belt cleaner and keep it in good working order:

1. Check the condition of the blades regularly. If they are worn or damaged, replace them with new ones.

2. Keep the housing and bearings clean and free from debris.

3. Lubricate the moving parts regularly. This will help to prolong the life of the belt cleaner and keep it running smoothly.

4. Inspect the tensioning system regularly to ensure that it is working properly.

Maintaining a conveyor belt is essential for ensuring the long-term productivity of your factory or manufacturing floor. Properly caring for and servicing the conveyor belt can prevent serious and costly breakdowns that can cause significant delays in production. With a few simple steps and regular maintenance checks, you can keep your conveyor belt running smoothly.

One of the most important aspects of keeping your conveyor belt in top condition is to inspect it regularly and address any potential problems right away. Be sure to look out for signs of wear or tear such as frayed edges, cracked conveyor belts, or other damage caused by heavy use. In addition, make sure to check the tension on the belt at least once a month to ensure it’s working properly. If necessary, adjust or replace parts as needed.

Step 1: Inspect Regularly

It is vital to maintain a conveyor belt in order to keep it operating efficiently. The first step of conveyor belt maintenance should be regular inspections. This will help detect any issues that may arise, allowing for quick and easy repairs before further damage occurs. Inspections should be done every day or as needed throughout the day, depending on the specific requirements of your system.

The goal of these inspections is to ensure that all components of the conveyor belt are in top condition and functioning properly. During an inspection, look for signs of wear or damage on the frame and moving parts, such as belts and chains. Check for loose bolts and screws that may need tightening or replacing if necessary. Additionally, inspect the drive motor and power supply to make sure they are working correctly. Finally, take note of any unusual noises coming from the conveyor belt system during operation.

Step 2: Clean and Lubricate

Maintaining a conveyor belt is an essential part of keeping it running smoothly and efficiently. Step two in the process of maintaining a conveyor belt is to clean and lubricate it. This step helps keep the system free of dirt and debris, as well as reduce friction between moving parts.

To begin cleaning and lubricating your conveyor belt, start by clearing away any dirt or debris that may have accumulated on its surface. This should be done carefully with a soft cloth to avoid damaging any components. After this has been done, use a mild detergent and warm water to remove tougher stains or dirt patches. Once all of the external surfaces have been cleaned, move on to lubricating key components such as bearings, gears, chains and sprockets. This will help prevent them from becoming corroded over time due to friction or water exposure.

Step 3: Repair or Replace Damaged Parts

Maintaining a conveyor belt is key to keeping the production line running at its peak efficiency. In Step 3, it’s time to repair or replace any damaged parts. Whether damage is caused by everyday wear and tear or from an unexpected accident, having the correct replacement parts ready will help ensure that downtime is kept to a minimum.

Before replacing any part, it’s important to carefully identify the source of any damage and assess whether repairing or replacing is necessary. If you are unsure of what needs to be done, contact an experienced professional who can advise on best practices for conveyor belt maintenance. Once you have determined which solution will best suit your situation, you can proceed with either repairs or replacements as needed.

Step 4: Make Adjustments

The fourth step in maintaining a conveyor belt is to make adjustments. Properly adjusting the tension on a conveyor belt helps ensure that it runs as efficiently and safely as possible. The amount of tension needed for optimal performance will depend on the particular belt model, so users should first refer to any manufacturer instructions that may be provided.

When adjusting the tension, it is important to pay attention to how much slack is in the system and how much pressure is being applied to the drive pulley. If too little slack exists, then there could be excessive wear and tear on both the conveyor belt and its associated components. Too much slack can also cause problems with power transmission or alignment issues. In addition, once adjustments have been made, they should be regularly monitored in order to maintain peak performance levels over time.

Step 5: Monitor Performance

When it comes to maintaining a conveyor belt, the fifth and final step is to monitor its performance. Regular monitoring of the machine’s performance is essential in order to identify potential problems before they occur or worsen. This step can help ensure that your conveyor belt continues to function optimally at all times.

First, you need to establish what kind of performance indicators you will use for your conveyor belt. Generally speaking, these are factors such as speed, power consumption, and throughput capacity. Once you have identified what data points you wish to monitor, it is important that you regularly check each indicator against expected values for accuracy. If any metrics fall outside of their normal range then it may signal an issue with the conveyor belt that needs addressing.

Conclusion: Essential Maintenance

Conveyor belts are essential for many industrial operations. To keep them functioning correctly, regular maintenance is required. Proper maintenance can ensure that the conveyor belt runs safely and efficiently. This article has explored the importance of essential conveyor belt maintenance and how it can help to extend the life of the system.

Cleaning and inspection should be carried out regularly, paying particular attention to any signs of wear or damage. Checking and adjusting tension levels, as well as lubrication points, will also prevent wear caused by friction between components. It is important to note that some elements may need replacing over time in order to maintain effectiveness. Lastly, aligning belts with pulleys properly will reduce strain on components which could eventually lead to belt failure if left unchecked.

- Please confirm your inquiry request as the usefulness.

- Please measure your application place size and count the quantity. If you have drawing, better send to us. If you have no drawing please tell me your application and tell me where do you want to use it, better to know the application equipment model, we can make drawing or solutions for you.

- We will making drawing as your demands or required products photos or pictures.

- Please confirm the size and quantity, especially the specifications of what you want so that I can supply the most precise guide and suggestions.

- Making samples as your exact requirements and appplications.

- Testing and confirm the samples and making upgrade if necessary.

- Placing order and prepare the production.

- Arrange the delivery after out of warehouse test.

- After-sale service follow the goods always.

Before purchase: Give the most professional guide for choosing the right products or service system.

After purchase: Warranty for 1 or 2 years as the application and your requirements. Any damage will be repair or replace new during warranty as long as use the products as the right way and normal wear of the products apart from any break by personal reasons.

After-sale: Always give the most professional suggestions for the products working status, give support for customers marketing developments of own brand business. Always repair as long as we keep cooperation.

Yes, we can provide existing sample for free, but a little sample charge for custom design, new customers are expected to pay for the delivery cost, the sample charge will be deducted from the payment for formal order.

For existing product, it takes 1-2 days; If you want your design, it may take 3-5 days depends on your design content.

We have our QC department empowered with a professional QC team. “Quality First, Cutomer Focus” is our quality policy, and we have Incoming Quality Control / In-process Quality Control / Out-going Qualtiy Control throughout our factory operations.

To withstand all the above extreme working environment requirements, Suconvey has to choose the best quality raw materials which can not only produced good performance silicone products but also have many outstanding advantages such as will not change to yellow even use for a long time, will not become brittle easily broken, will not shrink or expand although using for a long time, will also not easily change the specification to influence your machine operation. Only based on the above quality control, silicone products can be serviced for a long time to save your energy to replace them and your time waiting for the replacement so that the productivity is high.