Ibhanti leRubber Conveyor Hot Vulcanizing Press Machine

Inkampani yeRubber ye-Suconvey ibonelela ngebhanti yokuhambisa irabha ekumgangatho ophezulu otshisayo udibanisa umatshini wokushicilela. Umatshini oshushu wokudibanisa webhanti yokuhambisa ilaphu usetyenziswa ikakhulu kumashishini okudibanisa kunye nokulungiswa kwamabhanti okuhambisa anje ngesinyithi, umgodi, umzi-mveliso wamandla, izibuko, idokhi, isamente yezinto zokwakha, ishishini lemichiza, icuba, kunye nebala lokutya oluzenzekelayo.

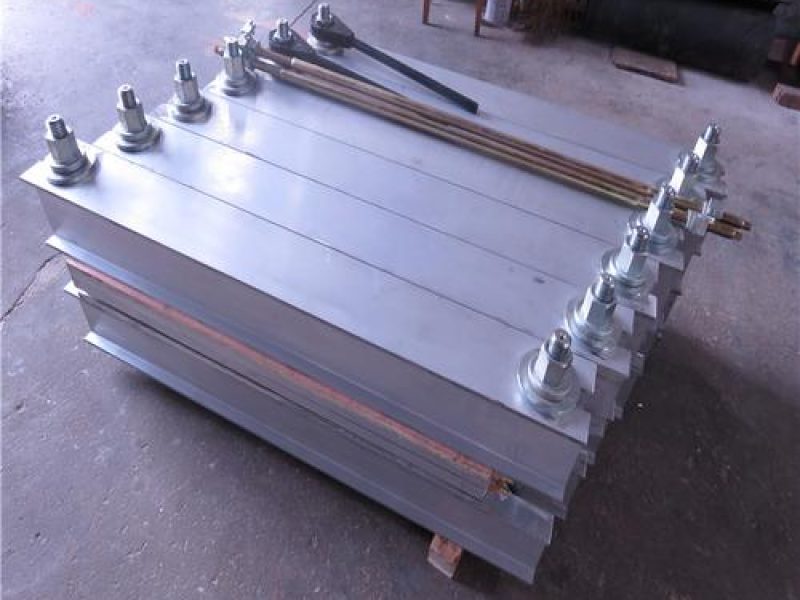

Umatshini woKucofa uShicilelo lwe-Hot Splicing Conveyor vulcanizing

Ezona mpawu

- Ubungakanani obukhulu boMshini: ukusuka kwi-300MM-6000MM;

- Umbane: 220V 380V 415V 660V 50HZ;

- Ixesha lokupholisa ngokukhawuleza: imizuzu eyi-15 (ukusuka kwi-145 degrees ukuya kwi-70 degrees okanye ngaphantsi);

- Ixesha lokunyusa amaqondo obushushu (ukusuka kwiqondo lobushushu eliqhelekileyo ukuya kwiqondo lobushushu) hayi ngaphezulu kwemizuzu engama-25;

- Umahluko wobushushu bomphezulu wesulfide: ±2°c.

- Uluhlu lohlengahlengiso lobushushu: 0 ~ 300 °c.

- Uxinzelelo lwe-Vulcanizing: 0 ~ 2.5 MPa (iinkcukacha zibhekiselele kwiinkcukacha zabasebenzisi kunye nokumakishwa kwefektri);

- Ixesha lokugcinwa kobushushu kwi-vulcanizing lingahlengahlengiswa ngokobunzima beebhanti zerabha;

- Ubude bebhanti yokuhambisa irabha yokudibanisa i-vulcanizing inokudityaniswa kunye ngamaqhekeza omnye okanye amaninzi ukuba kuyimfuneko;

- Ibhanti lokuhambisa irabha kunye noxinzelelo lwekhilogram efunekayo kwi-vulcanizing jointing xa uodola iimveliso.

- Abasebenzisi banokuodola iimpompo zombane ezingasetyenziswanga ukongezelela ngokweemfuno.

Iinkcukacha zeSuconvey Hot Vulcanizing Press Machine | ||||||

Umyalelo weNombolo | Ububanzi bebhanti(mm) | Into(mm) | Ipleyiti yokufudumeza(mm) | Amandla (kw) | Ubungakanani (mm) | Ubunzima (kg) |

SUH/LH-650 | 650 | 650 x 830 | 830 x 820 | 9.8 | 1080 x 165 x 170 | 470 |

650 x 1000 | 1000 x 820 | 11.8 | 540 | |||

SUH/LH-800 | 800 | 800 x 830 | 830 x 995 | 11.97 | 1250 x 165 x 170 | 635 |

800 x 1000 | 1000 x 995 | 14.4 | 735 | |||

SUH/LH-1000 | 1000 | 1000 x 830 | 830 x 1228 | 14.7 | 1450 x 165 x 170 | 865 |

1000 x 1000 | 1000 x 1228 | 17.8 | 955 | |||

SUH/LH-1200 | 1200 | 1200 x 830 | 830 x 1431 | 17.2 | 1680 x 165 x 250 | 965 |

1200 x 1000 | 1000 x 1431 | 20.7 | 1150 | |||

SUH/LH-1400 | 1400 | 1400 x 830 | 830 x 1653 | 19.8 | 1900 x 165 x 250 | 1160 |

1400 x 1000 | 1000 x 1653 | 23.8 | 1460 | |||

SUH/LH-1600 | 1600 | 1600 x 830 | 830 x 1867 | 22.3 | 2140 x 165 x 270 | 1320 |

1600 x 1000 | 1000 x 1867 | 27 | 1570 | |||

SUH/LH-1800 | 1800 | 1800 x 830 | 830 x 2079 | 24.9 | 2350 x 165 x 320 | 1480 |

1800 x 1000 | 1000 x 2079 | 30 | 1850 | |||

SUH/LH-2000 | 2000 | 2000 x 830 | 830 x 2303 | 27.6 | 2550 x 165 x 360 | 1530 |

2000 x 1000 | 1000 x 2303 | 33.2 | 1900 | |||

SUH/LH-2200 | 2200 | 2200 x 830 | 830 x 2478 | 29.7 | 2750 x 165 x 360 | 1700 |

2200 x 1000 | 1000 x 2478 | 35.8 | 2000 | |||

SUH/LH-2400 | 2400 | 2400 x 830 | 830 x 2678 | 31.8 | 2940 x 165 x 360 | 1850 |

2400 x 1000 | 1000 x 2678 | 38.9 | 2200 | |||

Usetyenziso olunokulungiswa komatshini wokuVulcanizing oshushu

- Iminyaka eyi-8 yamava okuvelisa

- Umgangatho ophezulu

- Iinkonzo zenkxaso emva kokuthengisa

- Ubungakanani obuMgangatho kunye noBungqongqo

Ibhanti yokuhambisa ilaphu

Umatshini webhanti olungiswayo otshintshayo oshushu

Ibhanti leNgxoxo yeNtsimbi

ukukhanya Umatshini webhanti otshisayo weVulcanizing

Ibhanti leNayiloni yokuhambisa

Umatshini weBhanti oDibeneyo oDibeneyo oHlangeneyo

Andazi ukuba Uqale ngantoni?

Fumana isisombululo kwiProjekthi yakho

Malunga neNkampani

Qhagamshelana nathi

I-Suconvey Wholesale inokuba lula kwaye ikhuseleke.

Kungakhathaliseki ukuba luhlobo luni lomatshini webhanti otshisayo owufunayo, ngokusekelwe kumava ethu abanzi, sinokuwenza kwaye sikubonelele.

- IShenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Stephanie

- 86-13246961981

- [imeyile ikhuselwe]

Unxibelelwano lwasimahla

Fumana isicatshulwa simahla

Malunga neSUCONVEY

IiNkokheli kuMatshini wokuTyala oshushu

Umatshini we-vulcanizing we-SUH wamanzi opholileyo uxhotyiswe ngesixhobo sokujikeleza kwamanzi okupholisa. Isitya sokufudumeza sinesantya sokupholisa ngokukhawuleza kwaye sinokuchithwa kwimizuzu emi-5-10. Ngokukodwa kwimozulu eshushu, indawo yobushushu obuphezulu kunye nexesha lokwakha eliqinileyo, ukusetyenziswa kwalo matshini we-vulcanizing owenziwe ngamanzi unokuphucula ukusebenza kakuhle kunye nokunciphisa ixesha lokwakha. Amacandelo omatshini we-SUH opholisa amanzi apholileyo alula kwaye angashukunyiswa ngabasebenzi. Ngaphambi kofakelo, ukulungelelana kwamandla kunye nemithombo yamanzi kufuneka kuthathelwe ingqalelo. Sebenzisa umbhobho wamanzi okhethekileyo ukuze udibanise umthombo wamanzi wempompo kwimibhobho yamanzi okupholisa amacwecwe aphezulu kunye naphantsi okufudumeza kumatshini we-vulcanizing, kodwa musa ukukhupha amanzi okwangoku. Ngeli xesha, ubushushu rhoqo iqala de vulcanization rhoqo ubushushu ixesha liphelile. Ngeli xesha, vula amanzi ompompo kwaye udlulise amanzi kwisitya esishushu. Xa ubushushu behla kwinkqubo ixabiso elichaziweyo Xa isixhobo silungile, amanzi anokukhutshwa ukuze adibanise izixhobo, kwaye umsebenzi we-vulcanization ugqityiwe.

Malunga neNkampani

IiNzuzo zokuQhutywa okushushu

Oomatshini abashushu be-vulcanizing kwiibhanti zokuhambisa babonelela ngeenzuzo ezininzi ezenza ukuba zibe lukhetho olukhethiweyo kushishino. Enye yeenzuzo eziphambili ngumgangatho ophezulu we-splice ababonelela ngayo. Ubushushu obuphezulu kunye noxinzelelo olusetyenziswa ngexesha lokutshisa i-vulcanization liqinisekisa ibhondi eyomeleleyo kunye neyomeleleyo phakathi kwamacandelo ebhanti, okukhokelela ekuphuculweni kokusebenza komthumeli kunye nokuphila ixesha elide.

Ukongeza, oomatshini abashushu be-vulcanizing benza ukuba kube lula ukudityaniswa, ukususa iindawo ezibuthathaka okanye amaqhuma ahlala enxulunyaniswa nezinye iindlela zokudibanisa. Oku akunciphisi nje ixesha lokuphumla kodwa kwandisa ukhuseleko lokusebenza ngokunciphisa umngcipheko wokungaphumeleli kwebhanti ngokungalindelekanga. Ngaphezu koko, i-vulcanization eshushu ivumela ukulungelelaniswa kolungelelwaniso lwe-splice, ukulungiselela iimfuno ezithile zesicelo ezifana nokunyuka komthamo wokuthwala umthwalo okanye ukuchasana ne-abrasion, ngaloo ndlela kuphucula ukuguquguquka kunye nokusebenza kweenkqubo zokuhambisa.

Malunga noYilo

Ungawuthenga njani umatshini wokutshisa i-vulcanizing?

Oomatshini bethu, i-Suconvey, abavelisa izinto ezintsha kunye nomgangatho ophezulu wokutshisa i-vulcanizing baziwa kwishishini ngokuhlala ixesha elide, ukusebenza kakuhle, kunye nobuchwepheshe obuphambili. Ngokugxila ekuphuculeni okuqhubekayo kunye nokwaneliseka kwabathengi, sizibekele bucala njengomdlali ophambili kwimarike.

Ngaphambi kokuba wenze iodolo enye, nceda uqinisekise

- Ububanzi bebhanti yokuhambisa;

- Ubude beqhekeza;

- I-Angle ye-Bias;

- Uxinzelelo lweVulcanization.

- I-Voltage

Malunga Gcina

Uwugcina njani umatshini wokutshisa

Ukugcina kunye nokusebenza umatshini oshushu otshisayo kubalulekile ekuqinisekiseni ixesha elide kunye nokusebenza kakuhle kweenkqubo zebhanti yokuhambisa irabha.

Ukuhlolwa rhoqo kwezinto zokufudumeza komatshini, iinkqubo zoxinzelelo, kunye nolawulo lobushushu kubalulekile ukuze kubonwe nayiphi na imiba enokubakho ngaphambi kokuba inyuke.

Ukongeza, ukugcina ukulungelelaniswa okufanelekileyo kwamabhanti okuhambisa ngexesha lenkqubo ye-vulcanization kubalulekile ekufezekiseni ukusabalalisa ubushushu obufanayo kunye namandla okubopha okungaguqukiyo. Kukwabalulekile ukuba ulandele iishedyuli zokulondolozwa ezicetyiswa ngumvelisi zokutshintsha izinto zokufudumeza, amacandelo oxinzelelo, kunye nezinzwa zobushushu ukuqinisekisa ukusebenza ngokupheleleyo.

Ngaphaya koko, abaqhubi kufuneka baqeqeshwe kakuhle ekusebenziseni umatshini wokutshisa i-vulcanizing ukuthintela ukuguga okungeyomfuneko kunye nokukrazula kumalungu abalulekileyo. Oku kubandakanya ukuqonda ubuchule obufanelekileyo bokulungiselela ibhanti, ubushushu obucetyiswayo be-vulcanizing, kunye neendlela zokusebenzisa iintlobo ezahlukeneyo zamabhanti okuhambisa irabha. Ukuphunyezwa kweenkqubo zokulondolozwa okusebenzayo akuyi kwandisa kuphela ubomi benkonzo yomatshini wokutshisa i-vulcanizing kodwa kwakhona negalelo ekuphuculweni kwemveliso kunye nokunciphisa ixesha lokunciphisa kwimisebenzi yebhanti yokuhambisa.

FAQ

Imibuzo ephindaphindiweyo neempendulo

buza omnye umbuzo

Inkqubo eshushu edibeneyo yamabhanti okuhambisa ngumba obalulekileyo wokugcina kunye nokulungisa la macandelo abalulekileyo oshishino. Le nkqubo ibandakanya ukusetyenziswa kobushushu kunye noxinzelelo lokudibanisa iziphelo ezimbini zebhanti yokuhambisa kunye, ukuqinisekisa uxhulumaniso oluqinileyo noluhlala ixesha elide. Xa iqhutywe ngokufanelekileyo, inkqubo edibeneyo eshushu ibangela ukuhlanganiswa okungenamthungo, ukuvumela ibhande lokuhambisa ukuba lisebenze ngokufanelekileyo ngaphandle komngcipheko wokuhlukana okanye ukungaphumeleli. Yinkqubo ecokisekileyo efuna ukuchaneka kunye nobuchule ukuze kufikelelwe kwisiphumo esisiso.

Enye into ephambili kwinkqubo edibeneyo eshushu kukukhethwa kwezinto ezifanelekileyo kunye ne-adhesives. Uhlobo lwerabha ekhompawundi, ilaphu, kunye nencamatheliswayo esetyenziswayo inokuchaphazela kakhulu amandla kunye nobude bomdibaniso. Ngaphezu koko, ulawulo oluchanekileyo lokushisa ngexesha lokufudumala ludlala indima ebalulekileyo ekuqinisekiseni ukuba izinto eziphathekayo zibond ngokufanelekileyo ngaphandle kokwenza umonakalo okanye ubuthathaka besakhiwo sebhanti yokuhambisa. Ukuqonda le miba kubalulekile ekufezekiseni amajoyina ashushu athembekileyo amelana nobunzima bokusebenza okuqhubekayo kwiindawo ezahlukeneyo zoshishino.

Ukuqukumbela, ukuqonda inkqubo edibeneyo eshushu kubaluleke kakhulu kumashishini axhomekeke kwiinkqubo zokuthutha ukugcina ukusebenza kakuhle. Ngokuqonda ukuntsonkotha kwayo kunye notyalo-mali kwizinto ezikumgangatho ophezulu kunye nabasebenzi abanezakhono, amashishini anokuqinisekisa ubomi obude benkonzo kumabhanti abo okuhambisa ngelixa enciphisa ixesha lokuphumla ngenxa yokulungiswa okanye ukutshintshwa. Njengoko itekhnoloji iqhubeka nokuhambela phambili, kubalulekile kwiingcali kweli candelo ukuba bahlale benolwazi malunga neendlela ezintsha kunye nezinto ezintsha ezinokuphucula ngakumbi lo mba ubalulekileyo wokugcinwa kwebhanti lokuhambisa.

Kukho iintlobo ezininzi zeenkqubo ezidibeneyo ezishushu ezisetyenziselwa amabhanti okuhambisa, nganye ineempawu zayo kunye neenzuzo. Uhlobo lokuqala yinkqubo yokudibanisa i-overlap, ebandakanya ukuwela iziphelo zebhanti ezimbini kunye nokusebenzisa ubushushu kunye noxinzelelo lokuzidibanisa. Le ndlela inika umdibaniso oqinileyo onokumelana nemithwalo enzima kunye noxinzelelo.

Enye inkqubo edibeneyo eshushu edibeneyo yindlela yokuwelda iminwe, esebenzisa iiprotrusions eziyilwe ngokukodwa njengeminwe kwincam yebhanti ukwenza umdibaniso ongenamthungo. Le ndlela inikezela ukuguquguquka okugqwesileyo kwaye inciphisa uxinzelelo lwexinzelelo, iyenze ilungele izicelo ezifuna utshintsho olugudileyo ibhanti.

Ekugqibeleni, inkqubo ye-skiving ibandakanya ukususa inxalenye yesigqubuthelo esiphezulu sebhanti kwi-angle kwaye udibanise iileyile eziveziweyo. Oku kubangela umdibaniso ophantsi onciphisa ukuphazamiseka kweepulleys okanye amanye amacandelo kunye nenkqubo yokuhambisa. Nganye kwezi nkqubo ezidibeneyo ezishushu zineenzuzo zayo kwaye zikhethwa ngokusekelwe kwiimfuno ezithile zesicelo kunye neemfuno zokusebenza.

Ngaphambi kokuthenga: Nika esona sikhokelo sobuchwephesha sokukhetha iimveliso ezifanelekileyo okanye inkqubo yenkonzo.

Emva kokuthenga: Iwaranti ye-1 okanye iminyaka emi-2 njengesicelo kunye neemfuno zakho. Nawuphi na umonakalo uya kulungiswa okanye uthathe indawo entsha ngexesha lewaranti logama nje usebenzisa iimveliso njengendlela efanelekileyo kunye nokunxiba okuqhelekileyo kweemveliso ngaphandle kwekhefu ngenxa yezizathu zomntu.

Emva kokuthengisa: Soloko unika ezona ngcebiso zobuchwephesha kubume bokusebenza kweemveliso, nika inkxaso kubathengi bentengiso yophuhliso lweshishini lophawu lwakho. Soloko ulungisa nje ukuba sigcina intsebenziswano.