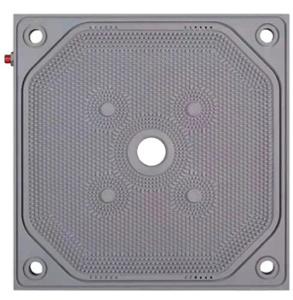

Umgangatho oPhakamileyo Lungiselela Isihluzi soMvelisi wepleyiti yokucofa

Iipleyiti zokucoca ezikumgangatho ophezulu ziqinisekisa ukuhluzwa ngokufanelekileyo ngokubonelela ngoxinzelelo olufanayo kwikhekhe lokucoca, okukhokelela ekugcinweni kwamasuntswana aphezulu kunye nokucocwa ngokucokisekileyo. Ezi pleyiti zenzelwe ukumelana nobushushu obuphezulu kunye neemeko zoxinzelelo, zibenza zihlale kwaye zithembeke ekusebenzeni ngokuqhubekayo. Ukongeza, itekhnoloji yepleyiti ephucukileyo yenze ukuba abavelisi bavelise iipleyiti ezinonyango olongeziweyo lomphezulu onciphisa ukuvala kunye nokuphucula ukusebenza kakuhle.

Ipleyiti yesihluzi soMyili weSihluzo soShicilelo

Ezona mpawu

- Ubungakanani: Ifumaneka ngokobukhulu ukusuka kwi-400mm ukuya kwi-2.1MX 2.1M, iiPleti zeFilter eziRare ziyafumaneka

- Ubungakanani obuqhelekileyo: 400, 470, 500, 630, 800, 915, 1000, 1200, 1400, 1500, 1500×2000 kunye ne2000x2000 mm

- I-sludge inlet: I-inlet esembindini, i-inlet ephakathi, i-inlet yekona

- Material: Yenziwe ngePolypropylene eGqibelekayo, irabha, intsimbi engatyiwa, okanye intsimbi ekhandiweyo

- Izicelo: Ishishini leMigodi, iShishini leMichiza, iShishini leShishini, iShishini lokuTya kunye neSiselo, iShishini lamanzi amdaka

- Iindidi zepleyiti yokucoca isihluzi:

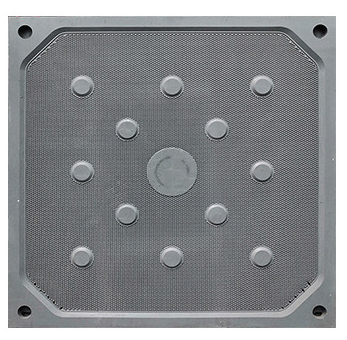

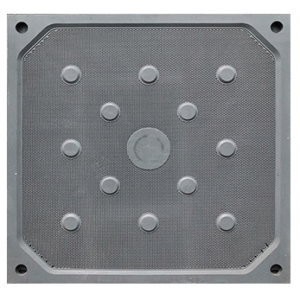

- I-Recessed Chamber filter plate

- Ipleyiti yokucofa icwecwe legumbi elingafakwanga gasketed

- Ipleyiti kunye nesakhelo sokucofa ipleyiti yokucoca

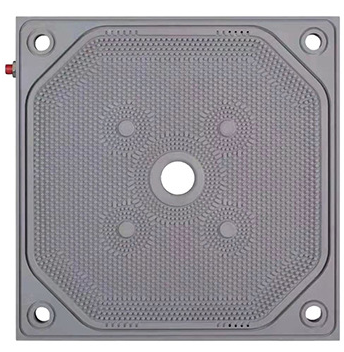

- I-Membrane cofa ipleyiti yokucoca

- Ezona mpawu:

- Ukumelana neekhemikhali: Ukumelana nomhlwa okunamandla, ukumelana neasidi, ialkali kunye nokhukuliseko lwetyuwa ukuya kumlinganiselo othile

- Ubomi obude benkonzo: Iplati yokucoca i-polypropylene eyomeleziweyo eneempawu zekhemikhali ezizinzileyo.

- Inkxaso yelaphu lokuhluza

- Uzinzo lobushushu

- Ubungakanani obahlukeneyo obukhoyo, bunokwenziwa ngokwezifiso

Iindidi zoShicilelo lwePleti yesihluzi

- Iminyaka eyi-8 yamava okuvelisa

- Umgangatho ophezulu

- Iinkonzo zenkxaso emva kokuthengisa

- Ubungakanani obuMgangatho kunye noBungqongqo

Ipleyiti yesihluzi sePolypropylene

I-Acid kunye ne-alkali ukumelana

Ipleyiti yesihluzi sePleyiti kunye nesakhelo

Ukumelana nobushushu obuphezulu kunye nePhantsi

I-Membrane Cwiza ipleyiti yesihluzi

Ukutyeba kwekeyiki ethambileyo

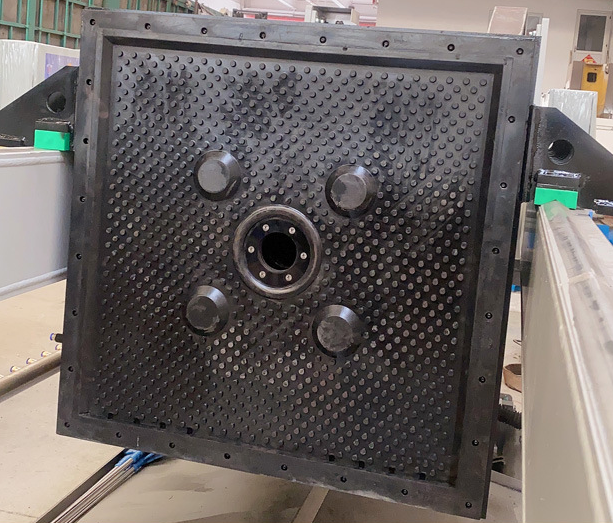

Ipleyiti yesihluzi serabha

Ukuphatha ngokulula

I-Recessed Chamber Filter Plate

Ukutshintsha ipleyiti ezenzekelayo kunokwenzeka

Lungiselela ipleyiti yesihluzi

Ezona ndleko ziphantsi zokukhupha amanzi

Andazi ukuba Uqale ngantoni?

Fumana isisombululo kwiProjekthi yakho

Malunga neNkampani

Qhagamshelana nathi

I-Suconvey Wholesale inokuba lula kwaye ikhuseleke.

Nokuba ufuna ipleyiti yokucoca enjani, ngokusekwe kumava ethu abanzi, sinokukwenzela kwaye sikubonelele yona.

- IShenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Stephanie

- 86-13246961981

- [imeyile ikhuselwe]

Unxibelelwano lwasimahla

Fumana isicatshulwa simahla

Malunga neSUCONVEY

IiNkokheli kwipleyiti yokucofa isihluzi

Uhambo lwenkampani yethu kushishino lwemveliso luchazwe kusukelo olungayekeleliyo lokugqwesa kunye nokusungula izinto ezintsha. Ngamashumi eminyaka yamava phantsi kwebhanti yethu, siye sabuhlonipha ubuchule bethu ekuveliseni iipleyiti zokucoca ezikumgangatho ophezulu ezisetyenziswa kumashishini ahlukeneyo. Ukuzibophelela kwethu kumgangatho kunye nokuchaneka kusenze saduma njengomenzi othembekileyo, owaziwa ngokuzisa iimveliso ezihlangabezana nezigqitha imigangatho ephezulu.

Siyazingca ngokukwazi kwethu ukuziqhelanisa nophuhliso lwenkqubela phambili yetekhnoloji, okusivumela ukuba sihlale siphambi kwegophe kwimakethi ehlala itshintsha. Ubuchwephesha beqela lethu abubonakali nje kumgangatho ophakamileyo weepleyiti zethu zokucoca isihluzi kodwa nasekuzinikeleni kwethu ekuboneleleni ngezisombululo ezilungiselelwe ukuhlangabezana neemfuno ezizodwa zomxhasi ngamnye. Ngophando oluqhubekayo kunye nophuhliso, siye sakwazi ukwenza izinto ezintsha kunye nokwandisa iinkqubo zethu zokuvelisa, okukhokelela kwiimveliso ezibonelela ngokusebenza okungafaniyo kunye nokuphila ixesha elide.

Malunga neNkampani

Izibonelelo zeepleyiti zokucoca ezikumgangatho ophezulu

Iipleyiti ezikumgangatho ophezulu zidlala indima ebalulekileyo ekusebenzeni ngokufanelekileyo kunye nokusebenza kweenkqubo zokucoca. Ezi pleyiti zenzelwe ukumelana noxinzelelo oluphezulu kunye nokubola, ukuqinisekisa ukusebenza kakuhle kunye nokuqina. Ngokusebenzisa iipleyiti ezikumgangatho ophezulu, amashishini anokunciphisa ixesha lokunciphisa ngenxa yokugcinwa kunye nokutshintshwa, okukhokelela ekunyuseni kwemveliso kunye nokugcinwa kweendleko kwixesha elide.

Ngaphezu koko, iipleyiti ezikumgangatho ophezulu zinceda ukufezekisa iziphumo ezingcono zokuhluza ngokubonelela ngobunzima bekeyiki efanayo kunye nokunciphisa ukuvuza ngexesha lokusebenza. Oku kuqinisekisa ukuba i-filtrate yokugqibela ihlangabezana nemigangatho efunekayo kwaye iyanciphisa ilahleko yemveliso. Kumashishini afana namayeza, ukusetyenzwa kokutya, kunye nemigodi, apho iimfuno ezingqongqo zokuhluza ziyimfuneko, utyalo-mali kwiipleyiti zokucoca ezikumgangatho ophezulu ziyimfuneko kwiinkqubo zemveliso ezingaguqukiyo nezithembekileyo.

Malunga Material

Izinto eziphezulu kwiipleyiti ezizinzileyo kunye nezisebenzayo

Izinto ezikumgangatho ophezulu zisisiseko sokucoca iipleyiti eziqinileyo nezisebenzayo. Njengomenzi wepleyiti yokucoca ekumgangatho ophezulu, siyakuqonda ukubaluleka kokusebenzisa izixhobo eziphezulu zokuqinisekisa ukusebenza okuhlala ixesha elide. Iipleyiti zethu zenziwe ngepolypropylene yeprimiyamu, enika ukuxhathisa okukhethekileyo kwi-corrosion, abrasion, kunye nomonakalo weekhemikhali. Oku kuqinisekisa ukuba iipleyiti zethu ziyakwazi ukumelana neemfuno ezingqongqo zeenkqubo zokuhluza, zibonelela ngeziphumo ezithembekileyo nezingaguqukiyo ekuhambeni kwexesha.

Ngaphaya koko, ukusetyenziswa kwemathiriyeli ekumgangatho ophezulu kwiipleyiti zokucofa izihluzi kunegalelo ekwandiseni impumelelo kwimisebenzi yokucoca. Umphezulu ogudileyo kunye nesakhiwo esifanayo se-polypropylene sivumela ukukhululwa kwekhekhe ngokufanelekileyo ngexesha lokukhutshwa kwamanzi, ukunciphisa amaxesha okujikeleza kunye nokwandisa imveliso. Ukongezelela, ezi zixhobo eziphezulu zenza ukuba iipleyiti zethu zigcine ingqibelelo yazo phantsi kweemeko zoxinzelelo oluphezulu, ziqinisekisa iimfuno ezincinci zokugcina kunye nobomi benkonzo eyandisiweyo. Ngokubeka phambili izinto ezisemgangathweni kwiinkqubo zethu zokuvelisa, sizama ukuhambisa ukuqina okungenakulinganiswa kunye nokusebenza kakuhle kwiimfuno zokucoca zabathengi bethu.

Malunga neSiko

Izisombululo ezilungiselelwe iimfuno ezithile zokuhluza

Xa kuziwa ekuhlangabezaneni neemfuno ezithile zokuhluza, isayizi enye ngokuqinisekileyo ayifanelanga yonke. Yiyo loo nto ukwenziwa ngokwezifiso ligama lomdlalo xa kufikwa kwiipleyiti zokucoca. Ngezisombululo ezilungiselelweyo, amashishini anokuqinisekisa ukuba iinkqubo zabo zokuhluza zilungiselelwe ukusebenza kakuhle kunye nokusebenza kakuhle. Nokuba yimfuno yobukhulu obukhethekileyo, uqwalaselo lwemathiriyeli eyodwa, okanye iimeko ezithile zokusebenza, iinketho zokwenza ngokwezifiso zivumela ukulingana okuthe ngqo okusemgangathweni okukhethwa kukho ngaphandle kweshelufu akunakubonelelwa.

Ngokunikezela ngezisombululo ezilungiselelweyo, abavelisi beepleyiti zokucoca baxhobisa amashishini ukuba ajongane nemingeni yawo eyodwa ngokuzithemba. Le ndlela ayigcini nje ukwandisa ukusebenza kodwa inokunciphisa ixesha lokunciphisa kunye neendleko zokugcina ngokubonelela ngesisombululo esilungiselelwe ngokukodwa ukuhlangabezana neemfuno ezichanekileyo zesicelo. Ukusuka kwiingubo ezikhethekileyo ukuya kuhlengahlengiso lwesiko, ukukwazi ukwenza ngokwezifiso iipleyiti zokucoca ukucoca kuvula ilizwe lamathuba amashishini ajonge ukuphakamisa iinkqubo zawo zokucoca ngaphaya kwemigangatho eqhelekileyo.

FAQ

Imibuzo ephindaphindiweyo neempendulo

buza omnye umbuzo

Iipleyiti zokucoca ziyinxalenye ebalulekileyo kwinkqubo yokuhluza, zisebenzela injongo yokwahlula izinto eziqinileyo kulwelo. Ezi cwecwe ziza kuyilo olwahlukeneyo kunye nemathiriyeli, nganye ilungiselelwe iimfuno ezithile zemizi-mveliso. Ukuqonda injongo yabo kubalulekile ekwandiseni impumelelo yokuhluza kunye nokufezekisa iziphumo ezinqwenelekayo.

Umsebenzi ophambili weepleyiti zokucoca ukucoca kukubonelela ngesakhiwo senkxaso yamalaphu okucoca ngelixa uvumela ukudlula kwefiltrate ngelaphu. Oku kwenza ukugcinwa kwezinto eziqinileyo ngaphakathi kwegumbi elenziwe ngamacwecwe, okukhokelela ekuhlukaneni okusebenzayo. Kubalulekile ukuqaphela ukuba iindidi zepleyiti ezahlukeneyo zibonelela ngamanqanaba ahlukeneyo omthamo wokuhluza kunye nokoma kwekeyiki, oko kukwenza kubaluleke ukukhetha iipleyiti ezifanelekileyo kwizicelo ezithile. Ngokubanzi, ukuqonda injongo yokucoca iipleyiti zokucoca kuluncedo ekuphuculeni ukusebenza kokucoca ngokubanzi kunye nokufezekisa izisombululo ezingabizi kakhulu kwiinkqubo zokwahlula okuqinileyo-ulwelo.

Uyilo lweepleyiti zokucoca isihluzi ludlala indima ebalulekileyo ekusebenzeni ngokufanelekileyo komatshini wokucoca. Amacwecwe ngokuqhelekileyo ayenziwe kwizinto ezifana ne-polypropylene, insimbi engenasici, okanye isinyithi esityhidiweyo, kwaye isakhiwo sazo senziwa ngononophelo ukuze simelane noxinzelelo kunye nokugqoka kunye nokukrazula okubandakanyekayo kwinkqubo yokucoca. Umsebenzi uwonke woyilo lwepleyiti yokucoca icwecwe kukubonelela ngeqonga eliqinileyo lokukhupha amanzi anodaka kunye nokwahlula izinto eziqinileyo kulwelo.

Omnye umba ophambili woyilo lwepleyiti yokucoca lulungiselelo kunye nobukhulu bamazibuko okutyisa kunye nemijelo yokukhupha. Ezi zinto zibekwe ngokucwangcisiweyo ukuze kuqinisekiswe ngokulinganayo ukusasazeka kwe-slurry kuwo wonke umhlaba wepleyiti nganye, ukwandisa ukusebenza kakuhle kokucoca. Ukongeza, ezinye ziyilo zibandakanya amagumbi akhethekileyo ahlaziyiweyo aphucula ukwakheka kwekeyiki kwaye aququzelele ukunkcenkceshela ngokucokisekileyo. Le ngqalelo kwiinkcukacha kuyilo lweepleyiti ekugqibeleni inegalelo kwiziphumo eziphuculweyo zokwahlula kunye namaxesha okuncitshiswa komjikelo, oko kuyenza ibe yingqwalasela ebalulekileyo kuyo nayiphi na inkqubo yokucoca.

Usetyenziso lwe-PP yokucoca ipleyiti yokucoca:

Ishishini lezemigodi: Iintsalela zezimbiwa, iziBonelelo zeziMbiwa, iMerrill-Crow, amalahle, iAluminium, iintsimbi ezixabisekileyo

Ishishini leMichiza: Iplastiki, iiResins, iipeyinti, iidayi, iiPigments

Ishishini loShishino: I-Metal Hydroxide, i-Phosphoric Acid, iSilica

Ukutya kunye noShishino lwesiselo: Ibhiya, iWayini, ioyile ezityiwayo, iJuice nokunye

Ushishino lwaManzi amdaka: Amanzi kaMasipala, iziCwangciso zokucocwa kwamanzi amdaka

- Ukuhluzwa kwe-Catalyst kunye nokwahlula;

- Ukuhluzwa kwegesi yobushushu obuphezulu kushishino lwepetrochemical, ukuhluzwa kwerhasi yokukhupha ibhedi ekhutshiweyo kwizityalo zepetrochemical, ukuhluzwa kwe-catalytic cracking slurry yeoli;

- Ukucocwa kwerhasi yobushushu obuphezulu kwishishini lesinyithi;

- Ukuhluzwa kwezinye iigesi zobushushu obuphezulu kunye nolwelo;

- Ukuhluzwa kwamaqondo obushushu ahlukeneyo ahlukeneyo, ulwelo oludlekayo kunye nezinto ezincedisayo kwishishini lepetrochemical;

- Ukuhluzwa kunye nokucocwa kwee-polymer ezahlukeneyo ezinyibilikayo kwishishini lefilimu yefiber yeekhemikhali;

- Ukuhluzwa kunye nokwahlulwa kwee-catalysts ezahlukeneyo kwishishini lamayeza;

- Isetyenziselwa ukuhanjiswa kwerhasi, izixhobo zeplate yentsimbi yebhedi;

- Isetyenziselwa ukuhlamba i-high-pressure backwashing of oil filters, njl.;

- Isetyenziselwa ukucoca ioyile ezityiwayo, iziselo kunye neentlobo ezahlukeneyo ze-slurries ezityiwayo;

- Isetyenziselwa ukucoca kunye nokucoca imveliso yamanzi amdaka.

Xa kuziwa kwiipleyiti zokucoca, ukhetho lwezixhobo ludlala indima ebalulekileyo ekumiseleni ukuqina kunye nokusebenza. Ezona ntlobo zixhaphakileyo zemathiriyeli ezisetyenziswa kwiipleyiti zokucoca isihluzi ziquka i-polypropylene, intsimbi ekhandiweyo, intsimbi engatyiwa, kunye nerabha. Isixhobo ngasinye sibonelela ngeenzuzo ezizodwa kunye neempawu ezihlangabezana neemfuno ezithile zokuhluza. Iipleyiti zePolypropylene zikhaphukhaphu, zixhathisa kwiikhemikhali, kwaye zifanelekile kwizicelo ezininzi eziqhelekileyo, ngelixa iipleyiti zentsimbi eziphosiweyo ziyaziwa ngamandla abo aphezulu kunye nokumelana nokushisa. Iipleyiti zentsimbi ezomeleleyo ziqhayisa ngokuxhathisa umhlwa kunye nokuphila ixesha elide, zizenza zilungele imekobume erhabaxa okanye enomhlwa. Ukongezelela, iipleyiti ezifakwe irabha zibonelela ngezakhono zokutywina ezigqwesileyo, zithintela ukuvuza ngexesha lenkqubo yokucoca.

Ngaphaya koko, ukhetho lwemathiriyeli lunokuchaphazela ukusebenza kakuhle kunye neendleko ezifanelekileyo zesixokelelwano sokucoca. Ngelixa iiplati ze-polypropylene zinokubonelela ngokufikeleleka kunye nokuguquguquka kwizicelo zokucoca kunye neemeko zokusebenza ezimodareyitha, insimbi engenasici okanye iiplate zentsimbi zivelele njengokhetho oluthembekileyo kwimisebenzi enzima kunye neemfuno ezifunekayo ezifana noxinzelelo oluphezulu okanye ukunyamezela ukushisa. Lilonke, ukuqonda iimpawu zemathiriyeli nganye kubalulekile ekukhetheni ipleyiti yokucoca echanekileyo elungele iimfuno ezithile zamashishini ezikhokelela ekuphuculweni kwemveliso kunye nobomi obude.

Ukusebenza kunye nokugcina iipleyiti zokucoca ngokucoca ngumba obalulekileyo wokuqinisekisa iinkqubo zokucoca ezisebenzayo nezisebenzayo. Ukusebenzisa iipleyiti, kubalulekile ukuqinisekisa kuqala ukuba zilungelelaniswe ngokufanelekileyo kwaye zifakwe ngokukhuselekileyo ngaphakathi kwesihluzo sokucoca. Oku kuya kunceda ukuthintela ukuvuza kunye nokwandisa ukusebenza kakuhle kokucoca. Ukongezelela, ukusebenza ngokufanelekileyo kubandakanya ukubeka iliso rhoqo amanqanaba oxinzelelo ukukhusela ukugqithiswa kweeplate, ezinokubangela umonakalo kunye nokunciphisa ukusebenza.

Ukugcinwa kweepleyiti zokucoca ukucoca kubandakanya ukucocwa rhoqo ukususa nayiphi na i-build-up okanye i-debris enokuthi ichaphazele umsebenzi wabo. Kubalulekile ukulandela iinkqubo ezicetyiswayo zokucoca ezibonelelwa ngumenzi, njengoko ukusebenzisa iindlela ezingafanelekanga okanye iikhemikhali zinokuphazamisa ingqibelelo yamacwecwe. Ngaphaya koko, ukuhlola naziphi na iimpawu zokuguga, ezinje ngeentanda okanye i-warping, kubalulekile ukuze kuchongwe xa ukutshintshwa okanye ukulungiswa kwakhona kunokuba yimfuneko. Ngokubambelela ekusebenzeni ngendlela eyiyo kunye neendlela zokulondoloza, ixesha lokuphila kwepleyiti yokucoca inokolulwa, kuncitshiswe ixesha lokuphumla kunye nokuqinisekisa ubulunga obungaguqukiyo bokucoca.

Ukuqukumbela, ukusebenza kunye nokugcina iipleyiti zokucoca isihluzi kufuna ingqalelo kwiinkcukacha kunye nokubambelela kwezona zenzo zilungileyo. Oku akuqinisekisi ukusebenza kakuhle kuphela kodwa kwandisa ixesha elide lezixhobo. Ngaphaya koko, ukubandakanya ugcino lwesiqhelo kwiiprothokholi zokusebenza kunokufaka isandla ekongiweni kweendleko ekuhambeni kwexesha ngokunciphisa iindleko zokulungisa kunye nokuphucula imveliso ngokubanzi kwiinkqubo zokuhluza kwimizi-mveliso.