Durable Rubber Solutions for Mining

Learn about the variety of mining that SUCONVEY services.

- 11 years manufacturing experience

- Good raw materials

- OEM and Free Samples

- Standard and Strict Dimension

SUCONVEY Service

Suconvey products mainly serve their purposes in these fields. We have a team of knowledgeable experts who dedicate to researching modified solutions.

SUCONVEYYour Technical Partner in Rubber Manufacturing

Suconvey is more than just a manufacturer. we are your partner committed to excellence with mining services and conveyor maintenance services. Our commitment goes beyond standard products to provide a level of customer service that sets us apart in the industry. When you choose to cooperate with us, our advantages are as follows:

Expertise and Experience

From mining, transportation, grinding to mineral processing, we have accumulated a wealth of application cases and are able to provide forward-looking material solutions for different types of minerals (such as highly abrasive gold ores and highly corrosive hydrometallurgical processes).

High quality raw materials

By employing nano-level reinforcing agents and a special anti-aging system, the Akron Abrasion index of the rubber is superior to the industry standard, significantly extending the service life of the product under high-impact environments.

Product Certificate

We have ISO 9001: 2015 Environmental Management Certificate, UL 94 V-0 Flame Resistance Certificate, ROHS Certificate and eight product patents.

Customized services

Based on the acidity, alkalinity, temperature and impact force of the material, we customize composite products with different hardness (Shore A 35-90) and thickness (such as rubber + metal, rubber + ceramic composite materials).

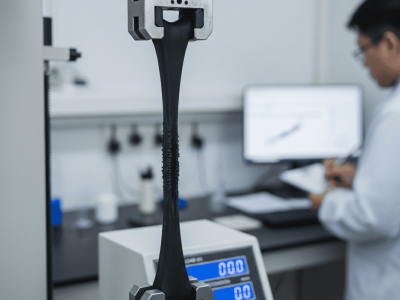

Quality Assurance

Large-scale vacuum vulcanizing machines and automatic temperature control systems are used to eliminate air bubbles and stress concentration inside the product, ensuring that the internal structure of large-sized mining rubber parts is dense and the performance is stable.

Comprehensive after-sales service

We provide 24/7 technical support for unexpected malfunctions. Our service team can provide on-site installation guidance, cold-bonding repairs, and system upgrade suggestions to maximize your customer’s return on investment (ROI).

Applications & Case Studies

Suconvey is your trusted provider in mining service. After years of dedicated work in the mining services industry, we have provided many clients with high-quality products based on their specific needs.

Safety Floor Mat in USA

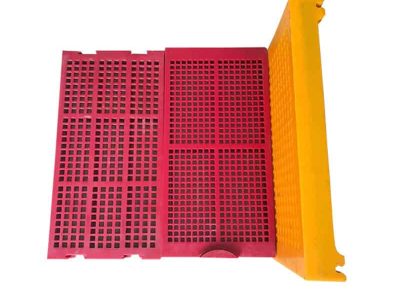

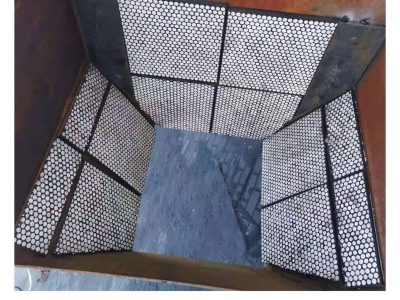

Screen Panels in Saudi Arabia

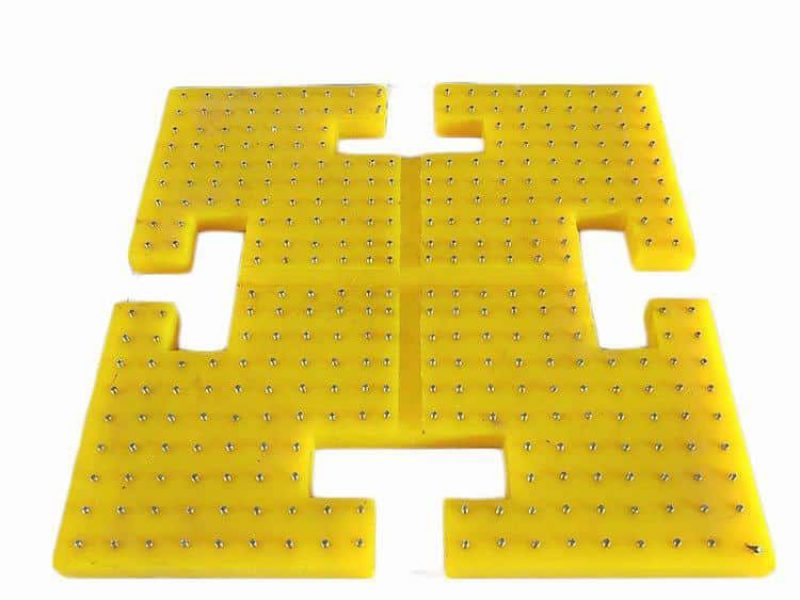

Impact Pads In Mozambique

Slurry Pipe in Australia

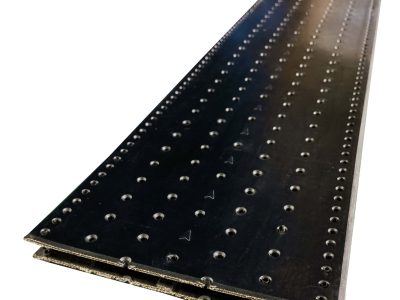

Liner Pads in Peru

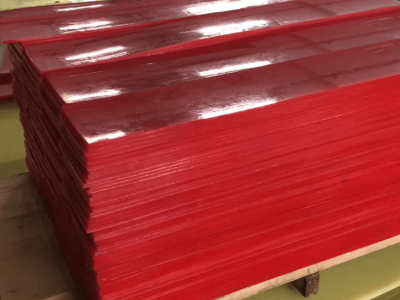

Filter Press Plate in Russia

More Than Just a Rubber Products Manufacturer

Customer Support

SUCONVEY customer specialists are devoted to providing flexible mining solutions for clients worldwide. Always keep you posted about the latest trend and technology. And we’re happy to give you a heads up for price changes!

Delivery Service

Our logistics teams are dedicated to providing expert service for all regions. We strive to maintain long-term relationships with shipping lines and agents.

Frequently Asked Questions

If your question is not listed, please contact us.

In many mining conditions, yes. Metal liners rely on hardness to withstand impact, while our high-molecular-weight rubber has excellent resilience, absorbing the impact energy of the ore through deformation, thus reducing wear. Based on actual cases, when processing ores of specific particle sizes, our rubber liners can last 1.5 to 3 times longer than high-manganese steel liners, with a weight reduction of approximately 50%, significantly reducing energy consumption.

We have a specialized library of corrosion-resistant formulations. We select special rubber compounds (such as EPDM, polyurethane, or high-performance synthetic rubber) based on your site’s chemical environment (such as the reagent composition in flotation processes or the acidity/alkalinity of hydrometallurgical processes). Each batch undergoes immersion testing to ensure it does not swell or detach under specific chemical media.

Absolutely. We have on-site 3D scanning and mapping capabilities. Even without the original factory drawings, our engineers can conduct on-site surveys and simulate the stress conditions using CAD/CAE. We will provide customized solutions based on the current wear characteristics of your equipment, such as “local thickening” or “structural optimization,” ensuring a 100% installation match.

We possess complete export qualifications and extensive international trade experience, and are familiar with the logistics regulations of mining areas in Southeast Asia, Africa, and South America. Our product packaging meets international shipping and tropical/extremely cold climate storage standards, ensuring it arrives on-site in perfect condition.

Very environmentally friendly.

Noise Reduction: Rubber parts reduce noise by 10-15 decibels compared to metal parts, protecting workers’ hearing and reducing environmental noise pollution.

Spill Prevention: Our spill skirts and sweepers significantly reduce material spillage and dust, lowering cleaning workload and reducing environmental dust concentration.

Recyclable: Our material formulations comply with RoHS and REACH requirements, and some products can be recycled after disposal.

After-sales service is not just about repair, but also about empowerment. We provide on-site or remote video training to guide your team on how to extend product lifespan by adjusting sweeper pressure, monitoring anti-slip pad wear, and more. We also provide an “On-site Maintenance Manual” to help you standardize equipment management.