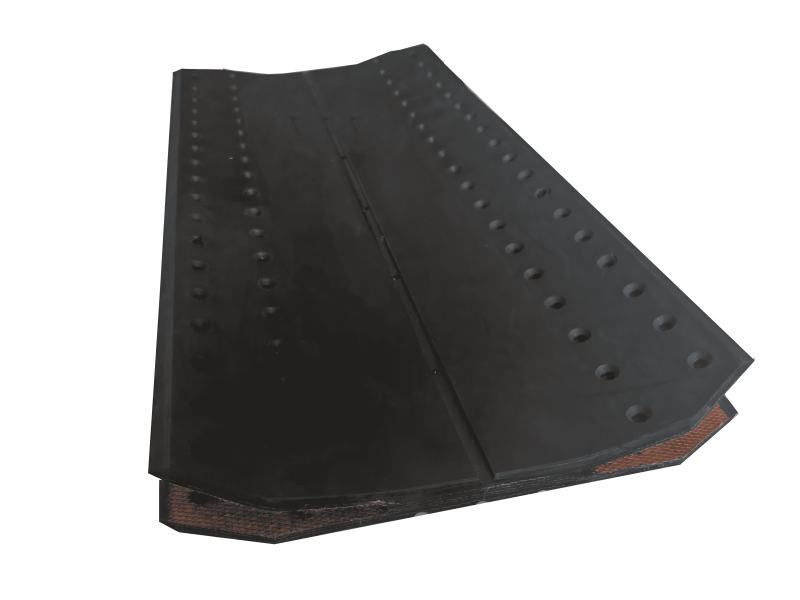

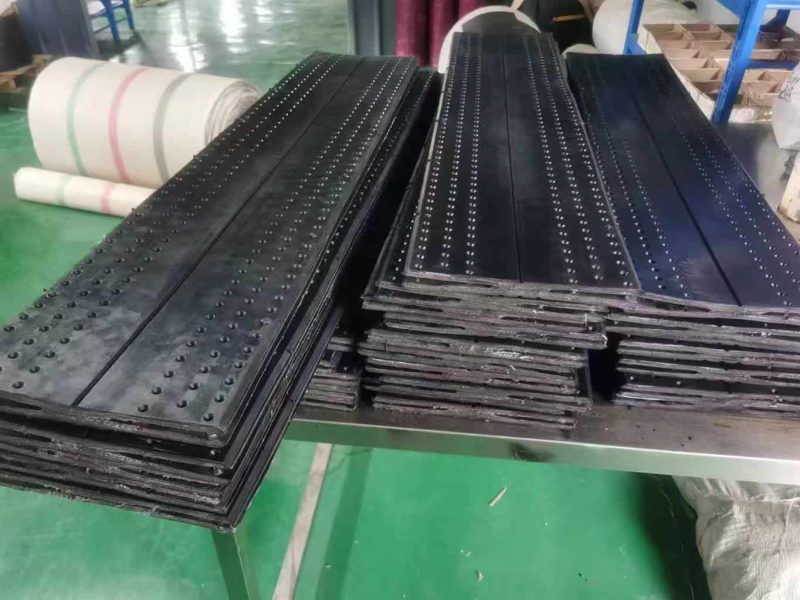

Quick screw splice for conveyor belt repair connector

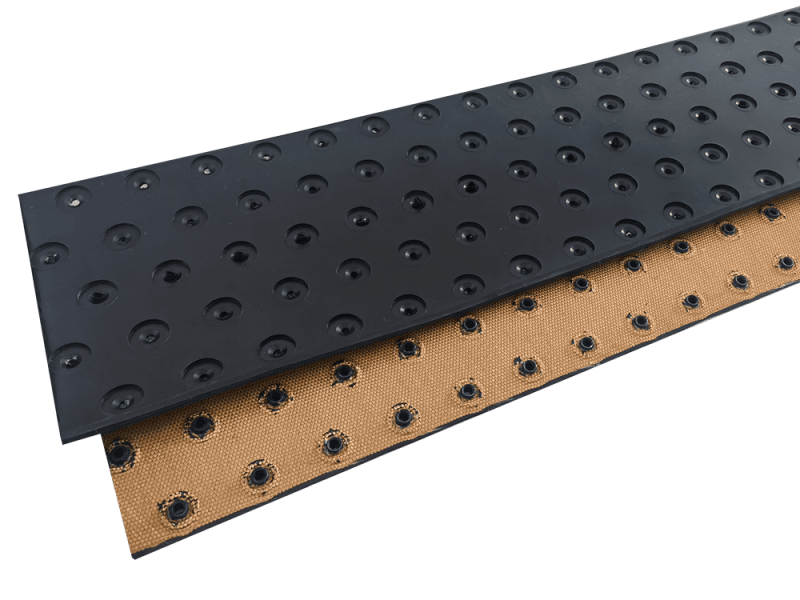

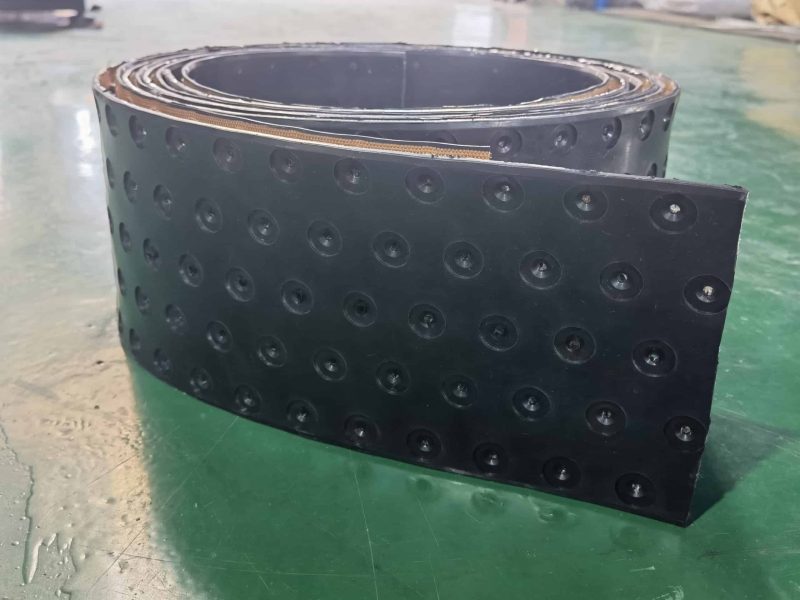

Suconvey Rubber company supplies high quality quick change seamless conveyor belt screw super connector. It is a new rubber conveyor belts connection method. It can be inserted at the conveyor belt cracks in any direction. It also can be used for the joint connection of the conveyor belts by connecting through the central positioning holes.

Mechanical Screws Splice for Conveyor Belt Repair

Key Features

- Custom Suconvey Screw Splice patented fasteners are available for any belt width, thickness, specification, and strength and supplied either in rolls to 25 meters (82 feet) or custom kits, delivered complete and ready for immediate installation;

- Heat-Resistant—Available

- High Wear Resistant—Available

- Anti-Magnetic—Available

- Acid and Alkali Resistance—Available

- Oil-Resistant—Available

- Fire-Retardant—Available

- Low Temperature—Available

- Friction Back—Available

- Easy—No Drilling Preparations Or Template;

- Quick—Reduces Downtime Significantly

- Safe—High Tensile Strength

Specifications of Suconvey Screw Super Fastener | |||||||

Suconvey Models | SUJ/SS-70 | SUJ/SS-120 | SUJ/SS-180 | SUJ/SS-200 | SUJ/SS-254 | SUJ/SS-260-HD | SUJ/SS-350-HD |

Specification | Splice | Splice | Splice | Splice | Splice&Insert Repair for Long Rips + Damage | Splice | Splice |

Top and Bottom Segments | TWO Pieces Separate | TWO Pieces Separate | TWO Pieces Separate | ONE Centre Joint | ONE Centre Joint | TWO Pieces Separate | ONE Centre Joint |

Recommended Service | Light | Standard | Medium | Medium | Medium – Heavy | Heavy | Heavy-Extreme |

Belt Tension – N/mm | Under 400 | 400 to 800 | 600 to 1200 | 600 to 1200 | 800 to 1200 | 1200 to 2000 | 1200 to 3150 |

Belt Tension – PIW | Under 285 | 285 to 575 | 430 to 860 | 430 to 860 | 575 to 860 | 860 to 1430 | 860 to 2255 |

Number of Plies | Canvas | Canvas | Canvas | Canvas | Canvas or Titanium | Canvas or Titanium | Canvas or Titanium |

Splice Width(mm) | 70 | 120 | 180 | 200 | 254 | 260 | 350 |

Splice Width(inches) | 2.75 | 4.72 | 7.09 | 7.87 | 10 | 10.2 | 13.8 |

Heat-Resistant | |||||||

Low-Temp | |||||||

High Wear Resistant | |||||||

Anti-Magnetic | |||||||

Oil-Resistant | |||||||

Fire-Retardant | |||||||

Friction Back | |||||||

Acid and Alkali Resistance | |||||||

Quick conveyor belt seamelss joint connector

- 8 years manufacturing experience

- High Quality

- After-sales support services

- Standard and Strict Dimension

SUJ/SS-70

Light

sUJ/SS-120

Standard

SUJ/SS-180

Medium

SUJ/SS-200

Medium

sUJ/SS-254

Medium – Heavy

SUJ/SS-260-HD

Heavy

SUJ/SS-350-HD

Heavy Extreme

Don’t Know What To Start With?

Get A Solution For Your Project

About Company

contact us

Suconvey Wholesale Can Be Easy & Safe.

No matter what kind of seamless screw splice you want, based on our extensive experience, we can manufacture and supply it for you.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

- Stephanie

- 86-13246961981

- [email protected]

Free Consultation

Get a free quote

About SUCONVEY

Leaders In belt mechanical joints

The Suconvey Screw Splice is a revolutionary solution in the realm of conveyor belt splice technology, designed to enhance both durability and efficiency. Unlike traditional splicing methods that often weaken over time due to wear or environmental factors, the Suconvey Screw Splice employs a unique mechanical fastening system that creates an ultra-strong bond between belt ends. This innovation not only prolongs the lifespan of conveyor belts but also reduces downtime for maintenance, thereby optimizing productivity in industrial processes.

Moreover, the versatility of the Suconvey Screw Splice makes it stand out in various applications—from mining and quarrying to food processing and packaging. Its ability to accommodate different belt thicknesses and types ensures seamless integration across operations without compromising performance. What sets it apart further is its ease of installation; even non-specialized personnel can implement splices effectively with minimal training. By investing in this advanced fastening system, industries can ensure uninterrupted workflow while minimizing operational costs tied to frequent repairs or replacements—making it an indispensable tool for modern conveyor systems.

About Company

Benefits of Super Belt Screw

The Suconvey Screw Splice is revolutionizing the conveyor belt maintenance landscape with its unique design that harmonizes strength and adaptability. One of its standout advantages is the simplicity of installation—users can quickly secure it in place without needing specialized tools or training. This not only saves valuable downtime during repairs but also empowers on-site teams to take charge, leading to increased operational efficiency.

Moreover, the Suconvey Screw Splice’s flexibility allows it to conform seamlessly to various belt types and sizes, making it an ideal solution for diverse industries. Unlike traditional fastening methods that often falter under heavy loads or extreme conditions, the Super Screw maintains consistent tension and robustness throughout its lifespan. By minimizing wear on both the belt and machinery components, businesses can significantly reduce long-term maintenance costs while enhancing overall productivity.

About Design

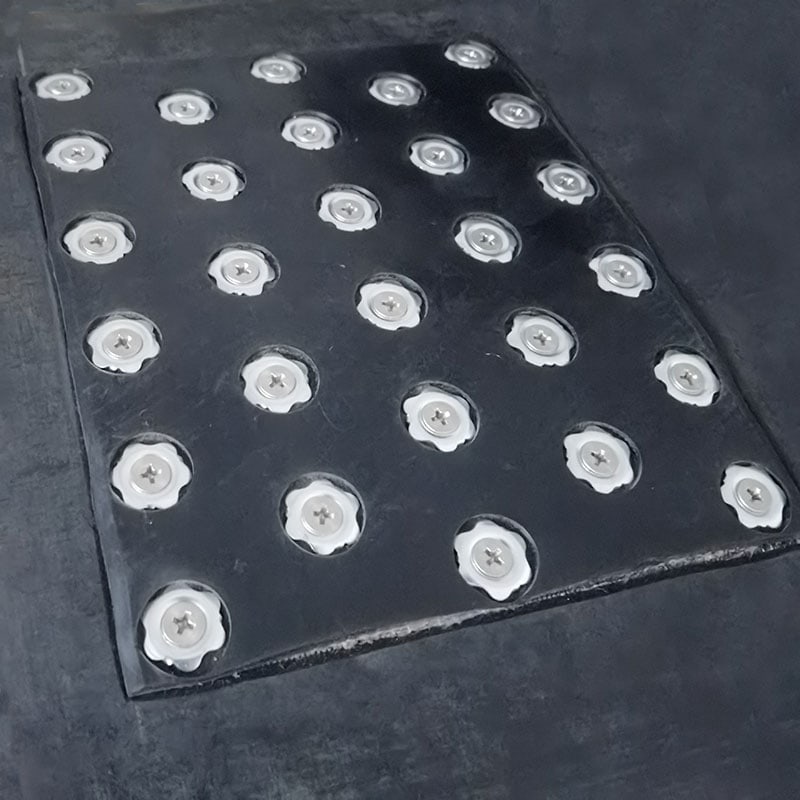

How to Install?

The installation of the Suconvey Screw Splice is a transformative process that significantly enhances the efficiency and longevity of conveyor belts. First, technicians must ensure that the belt ends are clean and aligned properly; this critical step not only promotes optimal bonding but also mitigates potential wear and tear on the system. Utilizing high-strength screws, each component is meticulously inserted and tightened in a sequence designed to evenly distribute tension; this innovative approach prevents common failure points found in traditional splicing methods.

What sets the installation apart is its versatility—the Suconvey Screw Splice can be adeptly utilized across various materials, including textiles and steel cords. Its unique design allows for quick adjustments without requiring extensive downtime, ultimately leading to increased productivity.

About Maintain

How to maintain vulcanizing machine

Regular maintenance is crucial for extending the life of your conveyor system, especially when integrating Suconvey Screw Splice. Start by routinely inspecting the screws and their placement to ensure they are tight and secure. Loose or misaligned screws can lead to uneven movement, increased wear on both the screws and the belt, and even unexpected downtime. Creating a standardized checklist for these inspections can help maintain consistency and catch small issues before they escalate.

Additionally, it’s essential to clean the conveyor regularly. Dirt and debris buildup around screw attachments can create friction points that prematurely wear down both the belt and hardware. Employing a dedicated cleaning routine not only enhances performance but also allows you to identify any areas needing immediate attention, further preventing future repairs. Lastly, staying in tune with your manufacturer’s recommendations for upkeep ensures you leverage their experience while enhancing operational efficiency—ultimately leading to a longer-lasting conveyor system that operates smoothly day after day.

FAQ

Most frequent questions and answers

ask more question

We have our QC department empowered with a professional QC team. “Quality First, Cutomer Focus” is our quality policy, and we have Incoming Quality Control / In-process Quality Control / Out-going Qualtiy Control throughout our factory operations.

To withstand all the above extreme working environment requirements, Suconvey has to choose the best quality raw materials which can not only produced good performance silicone products but also have many outstanding advantages such as will not change to yellow even use for a long time, will not become brittle easily broken, will not shrink or expand although using for a long time, will also not easily change the specification to influence your machine operation. Only based on the above quality control, silicone products can be serviced for a long time to save your energy to replace them and your time waiting for the replacement so that the productivity is high.

- Screw Belt Super Splice

- Rivet Hinge Fastener

- Stainless Steel Fastener