Umshini Wokucindezela Werabha Wokuthutha Ibhande Elishisayo Umshini Wokucindezela

Inkampani ye-Suconvey Rubber inikeza umshini wokucindezela wenjoloba wekhwalithi ephezulu oshisayo we-splicing vulcanizing press. Umshini oshisayo wokuhlanganisa ibhande lokuthutha indwangu usetshenziswa kakhulu ezimbonini zokuhlanganisa nokulungisa amabhande okuthutha afana ne-metallurgy, imayini, imboni yamandla, ichweba, idokhu, usimende wezinto zokwakha, imboni yamakhemikhali, ugwayi, kanye nenkambu yomugqa wokudla othomathikhi.

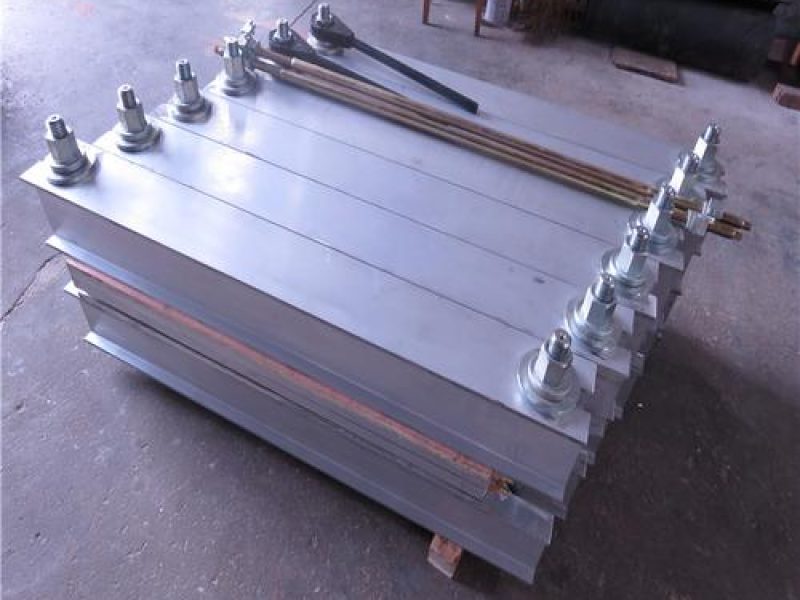

I-Hot Splicing Conveyor Belt Vulcanizing Press Machine

Izici Key

- Usayizi omkhulu womshini: kusuka ku-300MM-6000MM;

- Amandla kagesi: 220V 380V 415V 660V 50HZ;

- Isikhathi Sokupholisa Ngokushesha: imizuzu engu-15 (kusuka ku-145 degrees phansi kuya ku-70 degrees noma ngaphansi);

- Isikhathi sokukhuphuka kwezinga lokushisa (kusuka ekushiseni okujwayelekile kuya ekushiseni okushisayo) kungabi ngaphezu kwemizuzu engama-25;

- Umehluko wezinga lokushisa le-sulfide: ±2°c.

- Ibanga lokulungiswa kwezinga lokushisa: 0~300°c.

- Ukucindezela kwe-Vulcanizing: 0~2.5 MPa (imininingwane ibhekisela ekucacisweni kwabasebenzisi kanye nezimpawu zasembonini);

- Isikhathi sokulondolozwa kokushisa ukuze kufakwe i-vulcanizing singalungiswa ngokuvumelana nokuqina kwamabhande enjoloba;

- Ubude bokuhlukanisa ibhande lokuhambisa iraba lokuhlanganisa i-vulcanizing bungaxhunywa ndawonye ngesicucu esisodwa noma ezimbalwa uma kunesidingo;

- Ibhande lenjoloba lokuthutha kanye nokushuba kwekhilogremu okudingekayo ukuze kuhlanganiswe i-vulcanizing uma u-oda imikhiqizo.

- Abasebenzisi banga-oda amaphampu kagesi ayisipele ngokwezimfuneko.

Imininingwane ye-Suconvey Hot Vulcanizing Press Machine | ||||||

Inombolo ye-oda | Ububanzi bebhande(mm) | Into(mm) | Ipuleti lokushisisa(mm) | Amandla (kw) | Usayizi (mm) | Isisindo (kg) |

SUH/LH-650 | 650 | 650 x 830 | 830 x 820 | 9.8 | 1080 x 165 x 170 | 470 |

650 x 1000 | 1000 x 820 | 11.8 | 540 | |||

SUH/LH-800 | 800 | 800 x 830 | 830 x 995 | 11.97 | 1250 x 165 x 170 | 635 |

800 x 1000 | 1000 x 995 | 14.4 | 735 | |||

SUH/LH-1000 | 1000 | 1000 x 830 | 830 x 1228 | 14.7 | 1450 x 165 x 170 | 865 |

1000 x 1000 | 1000 x 1228 | 17.8 | 955 | |||

SUH/LH-1200 | 1200 | 1200 x 830 | 830 x 1431 | 17.2 | 1680 x 165 x 250 | 965 |

1200 x 1000 | 1000 x 1431 | 20.7 | 1150 | |||

SUH/LH-1400 | 1400 | 1400 x 830 | 830 x 1653 | 19.8 | 1900 x 165 x 250 | 1160 |

1400 x 1000 | 1000 x 1653 | 23.8 | 1460 | |||

SUH/LH-1600 | 1600 | 1600 x 830 | 830 x 1867 | 22.3 | 2140 x 165 x 270 | 1320 |

1600 x 1000 | 1000 x 1867 | 27 | 1570 | |||

SUH/LH-1800 | 1800 | 1800 x 830 | 830 x 2079 | 24.9 | 2350 x 165 x 320 | 1480 |

1800 x 1000 | 1000 x 2079 | 30 | 1850 | |||

SUH/LH-2000 | 2000 | 2000 x 830 | 830 x 2303 | 27.6 | 2550 x 165 x 360 | 1530 |

2000 x 1000 | 1000 x 2303 | 33.2 | 1900 | |||

SUH/LH-2200 | 2200 | 2200 x 830 | 830 x 2478 | 29.7 | 2750 x 165 x 360 | 1700 |

2200 x 1000 | 1000 x 2478 | 35.8 | 2000 | |||

SUH/LH-2400 | 2400 | 2400 x 830 | 830 x 2678 | 31.8 | 2940 x 165 x 360 | 1850 |

2400 x 1000 | 1000 x 2678 | 38.9 | 2200 | |||

Izicelo Zomshini Oshisayo Oshisayo Oshintshwayo

- Isipiliyoni seminyaka engu-8 sokukhiqiza

- Quality High

- Amasevisi asekela ngemva kokuthengisa

- Ubukhulu obujwayelekile nobuqinile

Ibhande le-Fabric Conveyor

Umshini Webhande Lokuhlukanisa Okushisayo Oshintshwayo

Ibhande Lensimbi Lentambo Yokuthutha

Ukukhanya Umshini Webhande Le-Vulcanizing Eshisayo

Ibhande Lokuthwala Inayiloni

Umshini Webhande Elihlanganisiwe Eliphathekayo

Angazi Uqale Ngani?

Thola Isixazululo Sephrojekthi Yakho

Mayelana nenkampani

Xhumana nathi

I-Suconvey Wholesale ingaba lula futhi iphephe.

Kungakhathaliseki ukuthi ufuna uhlobo luni lomshini webhande elishisayo elishisayo, ngokusekelwe ekuhlangenwe nakho kwethu okubanzi, singakukhiqizela futhi sikunikeze wona.

- I-Shenzhen Suconvey Rubber Products Co., Ltd.

- I-Ronglichang Industrial Park, No. 4 Zijing Road, District Longgang, Shenzhen City

- Stephanie

- 86-13246961981

- [i-imeyili ivikelwe]

Ukubonisana kwamahhala

Thola lesilinganiso samahhala

Mayelana ne-SUCONVEY

Abaholi Emshinini Wokugcwalisa Okushisayo

Umshini we-SUH opholisa amanzi opholile ufakwe idivayisi yokuhambisa amanzi okupholisa. Ipuleti lokushisa linejubane lokupholisa elisheshayo futhi lingahlakazwa emizuzwini emi-5-10. Ikakhulukazi esimweni sezulu esishisayo, imvelo yokushisa ephezulu kanye nesikhathi sokwakha esiqinile, ukusetshenziswa kwalo mshini we-vulcanizing opholile ngamanzi kungathuthukisa ukusebenza kahle komsebenzi futhi kufinyeze isikhathi sokwakha. Izingxenye zomshini we-SUH opholise amanzi opholile zilula futhi zinganyakaziswa abasebenzi. Ngaphambi kokufakwa, ukusebenziseka kwamandla nemithombo yamanzi kufanele kucatshangelwe. Sebenzisa ipayipi lamanzi elikhethekile ukuze uxhume umthombo wamanzi kampompi namapayipi amanzi okupholisa amapuleti okushisa aphezulu naphansi omshini we-vulcanizing, kodwa ungawakhiphi amanzi okwamanje. Ngalesi sikhathi, izinga lokushisa elihlala njalo liqala kuze kube yilapho isikhathi sokushisa esivamile se-vulcanization sesiphelile. Ngalesi sikhathi, vula amanzi ompompi futhi udlulisele amanzi ku-hot plate. Lapho izinga lokushisa lehla kunqubo eshiwo inani Lapho okokusebenza sekulungile, amanzi angakhululwa ukuze ahlakaze imishini, futhi umsebenzi we-vulcanization usuqedile.

Mayelana nenkampani

Izinzuzo Zokuhlukanisa Okushisayo

Imishini eshisayo yokushisa amabhande okuthutha inikeza izinzuzo eziningana ezibenza babe ukukhetha okuthandwayo embonini. Enye yezinzuzo ezibalulekile yikhwalithi ephezulu ye-splice abayinikezayo. Izinga lokushisa eliphezulu nokucindezela okusetshenziswe ngesikhathi sokushiswa kwe-vulcanization kuqinisekisa isibopho esiqinile nesihlala isikhathi eside phakathi kwamasegimenti amabhande, okuholela ekusebenzeni okuthuthukisiwe kukonke komthumeli nokuphila isikhathi eside.

Ukwengeza, imishini yokushisa eshisayo inika amandla ukuhlanganisa okungenamthungo, ukuqeda amaphuzu angaba buthaka noma amaqhuqhuva avame ukuhlotshaniswa nezinye izindlela zokuhlanganisa. Lokhu akunciphisi nje kuphela isikhathi sokuphumula kodwa futhi kuthuthukisa ukuphepha kokusebenza ngokunciphisa ubungozi bokungaphumeleli kwamabhande okungalindelekile. Ngaphezu kwalokho, i-vulcanization eshisayo ivumela ukwenziwa ngendlela oyifisayo ukulungiselelwa kwe-splice, ukuhlinzekela izidingo ezithile zohlelo lokusebenza ezifana nokwanda komthamo wokuthwala umthwalo noma ukumelana nokuhuzuka, ngaleyo ndlela kuthuthukisa ukuguquguquka nokusebenza kwamasistimu okuthutha.

Mayelana Nomklamo

Ungawuthenga kanjani umshini oshisayo we-vulcanizing?

Imishini yethu, i-Suconvey, esungulayo nesezingeni eliphezulu eshisa izikhotha idume embonini ngokuhlala isikhathi eside, ukusebenza kahle, kanye nobuchwepheshe obuphambili. Ngokugxila ekuthuthukisweni okuqhubekayo kanye nokwaneliseka kwamakhasimende, sizibekele eceleni njengomdlali obalulekile emakethe.

Ngaphambi kokufaka i-oda elilodwa, sicela uqinisekise

- Ububanzi bebhande le-Conveyor;

- Ubude be-splice;

- I-Bias Angle;

- Ingcindezi ye-Vulcanization.

- voltage

Mayelana Nokugcina

Ungawugcina kanjani umshini we-vulcanizing

Ukugcina nokusebenzisa umshini oshisayo oshisayo kubalulekile ukuze kuqinisekiswe impilo ende nokusebenza kahle kwezinhlelo zamabhande erabha okuhambisa.

Ukuhlolwa njalo kwezinto zokushisisa zomshini, amasistimu okucindezela, nezilawuli zezinga lokushisa kubalulekile ukuze kutholakale noma yiziphi izinkinga ezingaba khona ngaphambi kokuba zinyuke.

Ukwengeza, ukugcina ukuhleleka okufanele kwamabhande okuthutha ngesikhathi senqubo ye-vulcanization kubalulekile ukuze kuzuzwe ukusabalalisa ukushisa okufanayo namandla okubopha angaguquki. Kubalulekile futhi ukulandela amashejuli okulungisa anconywe ngumkhiqizi wokushintsha izinto zokushisisa, izingxenye ze-pressurization, nezinzwa zokushisa ukuze uqinisekise ukusebenza kahle.

Ngaphezu kwalokho, ama-opharetha kufanele aqeqeshwe kahle ekusebenziseni umshini oshisayo ukuze agweme ukuguga okungadingekile ezingxenyeni ezibucayi. Lokhu kuhlanganisa ukuqonda amasu okulungiselela amabhande afanele, amazinga okushisa anconyiwe avuzayo, kanye nezindlela zokufaka izicelo zezinhlobo ezahlukene zamabhande enjoloba okuthutha. Ukusebenzisa izinqubo zokulungisa okusebenzayo ngeke nje kunwebe impilo yesevisi yomshini oshisayo kodwa futhi kuzofaka isandla ekukhiqizeni okuthuthukisiwe kanye nesikhathi esincishisiwe sokusebenza kwebhande lokuthutha.

Imibuzo Evame Ukubuzwa

Imibuzo eminingi nezimpendulo ezivamile

buza omunye umbuzo

Inqubo ehlangene eshisayo yamabhande okuthutha iyisici esibalulekile sokunakekela kanye nokulungisa lezi zingxenye ezibalulekile zezimboni. Le nqubo ihilela ukusetshenziswa kokushisa nokucindezela ukuze kuhlanganiswe amaphethelo amabili ebhande lokuthutha ndawonye, okuqinisekisa ukuxhumana okuqinile nokuqinile. Uma isetshenziswe kahle, inqubo ehlangene eshisayo iholela ekuhlanganisweni okungenamthungo, okuvumela ibhande lokudlulisa ukuthi lisebenze kahle ngaphandle kwengozi yokuhlukaniswa noma yokwehluleka. Kuyinqubo ecophelelayo edinga ukunemba nobungcweti ukuze kuzuzwe umphumela oncomekayo.

Isici esisodwa esiyinhloko enkambisweni ehlangene eshisayo ukukhethwa kwezinto ezifanele kanye nama-adhesive. Uhlobo lwenhlanganisela yerabha, indwangu, nokunamathelayo okusetshenzisiwe kungaba nomthelela omkhulu kumandla nokuphila isikhathi eside kwelunga. Ngaphezu kwalokho, ukulawulwa kwezinga lokushisa okunembile ngesikhathi sokushisa kudlala indima ebalulekile ekuqinisekiseni ukuthi izinto ezisetshenziswayo zibopha ngempumelelo ngaphandle kokwenza noma yimuphi umonakalo noma ukuncipha kwesakhiwo sebhande lokudlulisa. Ukuqonda lezi zici kubalulekile ekuzuzeni amalunga ashisayo athembekile amelana nobunzima bokusebenza okuqhubekayo ezindaweni ezihlukahlukene zezimboni.

Sengiphetha, ukwenza kahle inqubo ehlangene eshisayo kubalulekile ezimbonini ezithembele kumasistimu okuthutha ukuze zigcine ukusebenza kahle. Ngokuqonda ubunkimbinkimbi bayo kanye nokutshala imali ezintweni zokwakha zekhwalithi ephezulu kanye nabasebenzi abanamakhono, amabhizinisi angaqinisekisa impilo ende yesevisi yamabhande awo okuthutha kuyilapho enciphisa isikhathi sokuphumula ngenxa yokulungiswa noma ukushintshwa. Njengoba ubuchwepheshe buqhubeka buthuthuka, kubalulekile ukuthi ochwepheshe kulo mkhakha bahlale benolwazi mayelana namasu amasha nezinto ezintsha ezingase zithuthukise lesi sici esibalulekile sokunakekelwa kwebhande lokuthutha.

Kunezinhlobo eziningana zezinqubo ezishisayo ezihlangene ezisetshenziselwa amabhande okuthutha, ngalinye linezici zalo ezihlukile kanye nezinzuzo. Uhlobo lokuqala luyinqubo yokushisela okweqile, ehlanganisa ukugqagqana kwamabhande amabili kanye nokusebenzisa ukushisa nokucindezela ukuze kuhlanganiswe ndawonye. Le ndlela ihlinzeka ngokuhlanganyela okuqinile okungakwazi ukumelana nemithwalo esindayo kanye nokucindezeleka.

Enye inqubo edume ngokuhlanganyela eshisayo yindlela yokushisela egqigqana ngomunwe, esebenzisa ama-protrusions aklanywe ngokukhethekile afana nomunwe emaphethelweni ebhande ukuze akhe ilunga elingenamthungo. Le ndlela inikeza ukuguquguquka okuhle kakhulu futhi inciphisa ukugxila kwengcindezi, iyenze ifaneleke izinhlelo zokusebenza ezidinga ukuguqulwa kwebhande elibushelelezi.

Okokugcina, inqubo yokushushuluza ihilela ukususa ingxenye yekhava ephezulu yebhande nge-engeli bese uhlanganisa izingqimba eziveziwe. Lokhu kubangela ukuhlangana kwephrofayili ephansi okunciphisa ukuphazamiseka kwama-pulleys noma ezinye izingxenye kusistimu yokuthutha. Ngayinye yalezi zinqubo ezihlangene ezishisayo zinezinzuzo zayo futhi ikhethwa ngokusekelwe ezidingweni ezithile zohlelo lokusebenza kanye nezidingo zokusebenza.

Ngaphambi kokuthenga: Nikeza umhlahlandlela ochwepheshe kakhulu wokukhetha imikhiqizo efanele noma isistimu yesevisi.

Ngemuva kokuthenga: Iwaranti yeminyaka engu-1 noma emi-2 njengesicelo kanye nezidingo zakho. Noma yimuphi umonakalo uzolungiswa noma ubuyisele okusha ngesikhathi sewaranti inqobo nje uma usebenzisa imikhiqizo njengendlela efanele nokuguga okuvamile kwemikhiqizo ngaphandle kwanoma yikuphi ukuphumula ngezizathu zomuntu siqu.

Ngemva kokuthengisa: Njalo nikeza iziphakamiso ezichwepheshile zesimo sokusebenza kwemikhiqizo, nikeza amakhasimende usekelo lwentuthuko yokumaketha yebhizinisi lomkhiqizo wakho. Hlala ulungisa inqobo nje uma sigcina ukubambisana.