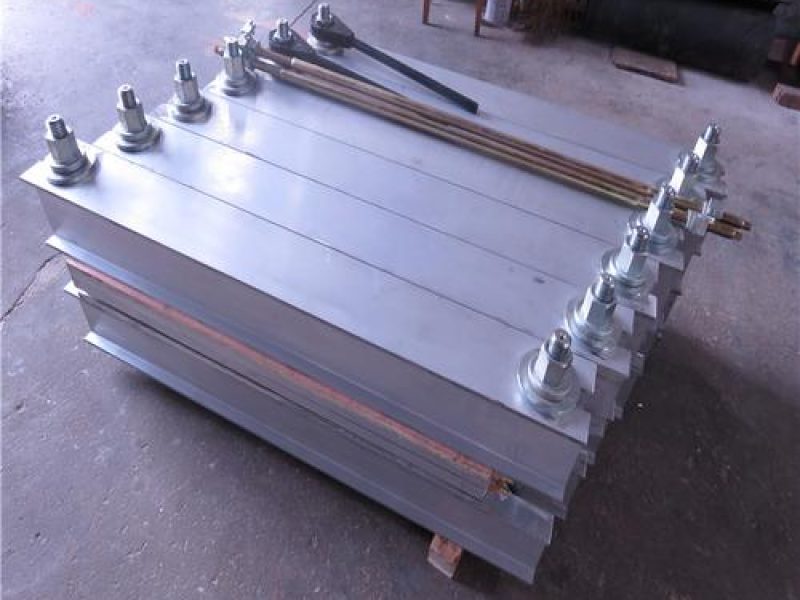

Rabara Conveyor Belt Hot Vulcanizing Press Machine

Khamphani ea Suconvey Rubber e fana ka lebanta la boleng bo holimo la rabara e tsamaisang rabara e chesang e kopanyang mochini oa khatiso oa vulcanizing. Mochini o chesang o kopanyang lebanta le tsamaisang masela o sebelisoa haholo liindastering bakeng sa ho kopanya le ho lokisa mabanta a conveyor joalo ka metallurgy, morafo, setsi sa motlakase, boema-kepe, boema-kepe, samente ea thepa ea kaho, indasteri ea lik'hemik'hale, koae le lebala la othomathike la lijo.

Hot Splicing Conveyor Belt Vulcanizing Press Machine

Features senotlolo

- Boholo ba Mochini: ho tloha 300MM-6000MM;

- Matla: 220V 380V 415V 660V 50HZ;

- Nako ea ho Pholisa ka potlako: Metsotso ea 15 (ho tloha ho likhato tse 145 ho ea ho likhato tse 70 kapa ka tlase);

- Nako ea ho phahamisa mocheso (ho tloha mocheso o tloaelehileng ho ea ho mocheso oa vulcanizing) eseng ho feta metsotso e 25;

- Phapang ea mocheso sebakeng sa sulfide: ±2°c.

- Sebaka sa ho fetola mocheso: 0 ~ 300°c.

- Khatello ea Vulcanizing: 0 ~ 2.5 MPa (lintlha li bua ka litlhaloso tsa basebelisi le matšoao a fektheri);

- Nako ea ho boloka mocheso bakeng sa vulcanizing e ka fetoloa ho ea ka botenya ba mabanta a rabara;

- Ho kopanya bolelele ba lebanta le tsamaisang rabara bakeng sa ho kopanya vulcanizing ho ka kopanngoa hammoho ka likotoana tse le 'ngoe kapa tse' maloa ha ho hlokahala;

- Rabara conveyor lebanta hammoho le tsitsipano ka kilogram e hlokehang bakeng sa vulcanizing jointing ha odara dihlahiswa.

- Basebelisi ba ka odara lipompo tsa motlakase tse bolokiloeng ho latela litlhoko.

Litlhaloso tsa mochini oa khatiso oa Suconvey Hot Vulcanizing Press | ||||||

Nete ea litaelo | Bophara ba lebanta(mm) | Ntho(mm) | Letlapa le futhumatsang(mm) | Matla (kw) | Size (limilimithara) | Boima ba 'mele (kg) |

SUH/LH-650 | 650 | 650: x 830 | 830: x 820 | 9.8 | 1080 x 165 x 170 | 470 |

650: x 1000 | 1000: x 820 | 11.8 | 540 | |||

SUH/LH-800 | 800 | 800: x 830 | 830: x 995 | 11.97 | 1250 x 165 x 170 | 635 |

800: x 1000 | 1000: x 995 | 14.4 | 735 | |||

SUH/LH-1000 | 1000 | 1000: x 830 | 830: x 1228 | 14.7 | 1450 x 165 x 170 | 865 |

1000: x 1000 | 1000: x 1228 | 17.8 | 955 | |||

SUH/LH-1200 | 1200 | 1200: x 830 | 830: x 1431 | 17.2 | 1680 x 165 x 250 | 965 |

1200: x 1000 | 1000: x 1431 | 20.7 | 1150 | |||

SUH/LH-1400 | 1400 | 1400: x 830 | 830: x 1653 | 19.8 | 1900 x 165 x 250 | 1160 |

1400: x 1000 | 1000: x 1653 | 23.8 | 1460 | |||

SUH/LH-1600 | 1600 | 1600: x 830 | 830: x 1867 | 22.3 | 2140 x 165 x 270 | 1320 |

1600: x 1000 | 1000: x 1867 | 27 | 1570 | |||

SUH/LH-1800 | 1800 | 1800: x 830 | 830: x 2079 | 24.9 | 2350 x 165 x 320 | 1480 |

1800: x 1000 | 1000: x 2079 | 30 | 1850 | |||

SUH/LH-2000 | 2000 | 2000: x 830 | 830: x 2303 | 27.6 | 2550 x 165 x 360 | 1530 |

2000: x 1000 | 1000: x 2303 | 33.2 | 1900 | |||

SUH/LH-2200 | 2200 | 2200: x 830 | 830: x 2478 | 29.7 | 2750 x 165 x 360 | 1700 |

2200: x 1000 | 1000: x 2478 | 35.8 | 2000 | |||

SUH/LH-2400 | 2400 | 2400: x 830 | 830: x 2678 | 31.8 | 2940 x 165 x 360 | 1850 |

2400: x 1000 | 1000: x 2678 | 38.9 | 2200 | |||

Likopo tse Fetohang tsa Mochini oa Vulcanizing O chesang

- Lilemo tse 8 phihlelo ea tlhahiso

- Boleng bo phahameng

- Litšebeletso tsa tšehetso ka mor'a thekiso

- Boemo bo tloaelehileng le bo thata

Lebanta la Conveyor la Lesela

Mochini o feto-fetohang oa Mabanta a chesang a chesang

Lebanta la Conveyor ea Tšepe

leseli Mochini oa lebanta o chesang oa Vulcanizing

Lebanta la Conveyor la Nylon

Mochini o Ts'oarehang o Kopanetsoeng oa Lebanta

Ha U Tsebe Hore na U Qala Ka Eng?

Fumana Tharollo Bakeng sa Morero oa Hao

Mabapi le Khampani

iteanye le rona

Suconvey Wholesale e ka ba bonolo ebile e bolokehile.

Ho sa tsotellehe hore na u batla mochine oa lebanta la vulcanizing o chesang, ho latela phihlelo ea rona e pharaletseng, re ka u etsetsa eona le ho u fa eona.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, No. 4 Zijing Road, Setereke sa Longgang, Motse oa Shenzhen

- Stephanie

- 86-13246961981

- [imeile e sirelelitsoe]

Kopano ea mahala

Fumana qotso ea mahala

Mabapi le SUCONVEY

Baetapele ba Mochini o chesang oa ho tšela

Mochini oa vulcanizing o pholileng oa metsi oa SUH o na le sesebelisoa sa ho potoloha ha metsi. Letlapa la ho futhumatsa le na le lebelo la ho pholile ka potlako 'me le ka qhaqhoa ka metsotso e 5-10. Haholo-holo maemong a leholimo a chesang, mocheso o phahameng oa mocheso le nako ea kaho e thata, tšebeliso ea mochine ona oa vulcanizing o pholileng ka metsi o ka ntlafatsa katleho ea mosebetsi le ho khutsufatsa nako ea kaho. Likarolo tsa mochini o pholileng oa metsi oa SUH o bobebe ebile o ka tsamaisoa ke basebetsi. Pele ho ts'ebetso, ho lokela ho nahanoa ka boiketlo ba mehloli ea matla le metsi. Sebelisa phala e khethehileng ea metsi ho hokahanya mohloli oa metsi a pompo ho lipeipi tsa metsi a pholileng tsa lipoleiti tse futhumatsang tse ka holimo le tse tlaase tsa mochine o senyang, empa u se ke ua ntša metsi ka nako eo. Ka nako ena, mocheso kamehla qala ho fihlela vulcanization kamehla mocheso nako e felile. Ka nako ena, bula metsi a pompo 'me u fetise metsi ho hot plate. Ha mocheso o theoha ho mokhoa o boletsoeng boleng Ha thepa e se e loketse, metsi a ka lokolloa ho qhaqha lisebelisoa, 'me ts'ebetso ea vulcanization e phethoa.

Mabapi le Khampani

Melemo ea Hot Splicing

Mechini e chesang ea vulcanizing bakeng sa mabanta a conveyor e fana ka melemo e mengata e etsang hore e be khetho e ratoang indastering. E 'ngoe ea melemo ea bohlokoa ke boleng bo phahameng ba splice eo ba fanang ka eona. Mocheso o phahameng oa mocheso le khatello e sebelisoang nakong ea vulcanization e chesang e tiisa maqhama a matla le a tšoarellang pakeng tsa likarolo tsa mabanta, e leng se etsang hore ho ntlafatsoe tshebetso ea conveyor ka kakaretso le bophelo bo bolelele.

Ho phaella moo, mechine e chesang ea vulcanizing e etsa hore ho be le seamless splicing, ho tlosa lintlha tse fokolang tse ka 'nang tsa e-ba teng kapa li-bulges tse atisang ho amahanngoa le mekhoa e meng ea ho kopanya. Sena ha se fokotse nako ea ho theoha bakeng sa tlhokomelo feela empa hape se matlafatsa ts'ireletso ea ts'ebetso ka ho fokotsa kotsi ea ho hlōleha ha mabanta ho sa lebelloang. Ho feta moo, vulcanization e chesang e lumella hore ho be le tlhophiso ea litlhophiso tsa splice, ho sebetsana le litlhoko tse khethehileng tsa kopo tse kang ho eketseha ha matla a ho jara kapa ho hanyetsa abrasion, kahoo ho ntlafatsa ho feto-fetoha le ts'ebetso ea litsamaiso tsa conveyor.

Mabapi le Moralo

Mokhoa oa ho reka mochine o chesang oa vulcanizing?

Mechini ea rona ea Suconvey, e tsoetseng pele le ea boleng bo holimo e tumme indastering ka ho tšoarella ha eona, ho sebetsa hantle le theknoloji e tsoetseng pele. Re tsepamisitse maikutlo ntlafatsong e tsoelang pele le khotsofalong ea bareki, re ikhethile re le sebapali sa bohlokoa 'marakeng.

Pele o etsa odara e le 'ngoe, ka kopo netefatsa

- bophara ba lebanta la conveyor;

- Bolelele ba ho arohana;

- Angle ea Leeme;

- Khatello ea vulcanization.

- Palo ea li-volts

Mabapi le Boloka

Mokhoa oa ho boloka mochini oa vulcanizing

Ho boloka le ho sebetsa mochini o chesang oa vulcanizing ho bohlokoa bakeng sa ho netefatsa nako e telele le katleho ea litsamaiso tsa mabanta a tsamaisang rabara.

Tlhahlobo ea khafetsa ea likarolo tsa mocheso oa mochini, litsamaiso tsa khatello, le taolo ea mocheso ke ea bohlokoa ho tseba mathata afe kapa afe a ka bang teng pele a ka mpefala.

Ho feta moo, ho boloka tatellano e nepahetseng ea mabanta a conveyor nakong ea ts'ebetso ea vulcanization ho bohlokoa bakeng sa ho fihlella kabo e tšoanang ea mocheso le matla a maqhama a tsitsitseng. Ho bohlokoa hape ho latela mananeo a tlhokomelo a khothaletsoang ke moetsi bakeng sa ho nkela lintho tse futhumatsang sebaka, likarolo tsa khatello ea maikutlo, le lisensara tsa mocheso ho netefatsa ts'ebetso e nepahetseng.

Ho feta moo, basebetsi ba lokela ho koetlisoa hantle ka ho sebelisa mochine o chesang vulcanizing ho qoba ho senyeha ho sa hlokahaleng le ho senya likarolo tsa bohlokoa. Sena se kenyelletsa ho utloisisa mekhoa e nepahetseng ea ho lokisa mabanta, mocheso o khothalelitsoeng oa vulcanizing, le mekhoa ea ts'ebeliso ea mefuta e fapaneng ea mabanta a tsamaisang rabara. Ho kenya ts'ebetsong mekhoa ea ts'ebetso ea ts'ebetso ea ts'ebetso ho ke ke ha lelefatsa bophelo ba ts'ebeletso ea mochini o chesang vulcanizing feela empa hape ho kenya letsoho ntlafatsong ea tlhahiso le ho fokotsa nako ts'ebetsong ea mabanta a conveyor.

LBH

Lipotso le likarabo tse ngata khafetsa

botsa potso e eketsehileng

Mokhoa o chesang o kopanetsoeng oa mabanta a conveyor ke karolo ea bohlokoa ea ho boloka le ho lokisa likarolo tsena tsa bohlokoa tsa indasteri. Ts'ebetso ena e kenyelletsa ts'ebeliso ea mocheso le khatello ho kopanya lipheletsong tse peli tsa lebanta la conveyor hammoho, ho netefatsa khokahano e matla le e tšoarellang. Ha e etsoa ka nepo, ts'ebetso ea motsoako o chesang e fella ka ho kopanngoa ho se nang moeli, ho lumella lebanta la conveyor hore le sebetse hantle ntle le kotsi ea ho arohana kapa ho hlōleha. Ke ts'ebetso e hlokolosi e hlokang ho nepahala le boiphihlelo ho fihlela sephetho se nepahetseng.

Ntho e 'ngoe ea bohlokoa ts'ebetsong ea motsoako o chesang ke khetho ea lisebelisoa tse loketseng le li-adhesives. Mofuta oa motsoako oa rabara, lesela le sekhomaretsi tse sebelisoang li ka ama matla le bophelo bo bolelele ba lenonyeletso. Ho feta moo, taolo e nepahetseng ea mocheso nakong ea ho futhumatsa e phetha karolo ea bohlokoa ho netefatsa hore thepa e tlama ka katleho ntle le ho baka tšenyo leha e le efe kapa ho fokola ha mohaho oa lebanta la conveyor. Ho utloisisa lintlha tsena ke habohlokoa bakeng sa ho finyella manonyeletso a chesang a ka tšeptjoang a mamellang mathata a ts'ebetso e tsoelang pele libakeng tse sa tšoaneng tsa indasteri.

Qetellong, ho tseba ts'ebetso e kopanetsoeng e chesang ke ntho ea bohlokoa bakeng sa liindasteri tse itšetlehileng ka lisebelisoa tsa conveyor ho boloka ts'ebetso e tsitsitseng. Ka ho utloisisa ho rarahana ha eona le ho tsetela thepa ea boleng bo holimo le mesebetsi e nang le boiphihlelo, likhoebo li ka netefatsa bophelo bo bolelele ba ts'ebeletso bakeng sa mabanta a bona a conveyor ha li ntse li fokotsa nako ea ho theoha ka lebaka la ho lokisoa kapa ho nkeloa sebaka. Ha thekenoloji e ntse e tsoela pele, ho bohlokoa hore litsebi lefapheng lena li lule li tseba ka mekhoa e mecha le mekhoa e mecha e ka ntlafatsang karolo ena ea bohlokoa ea tlhokomelo ea mabanta a conveyor.

Ho na le mefuta e 'maloa ea mekhoa e chesang e kopanetsoeng e sebelisetsoang mabanta a conveyor, e' ngoe le e 'ngoe e na le litšobotsi le melemo ea eona e ikhethang. Mofuta oa pele ke ts'ebetso ea ho tjheseletsa e kopanyang, e kenyelletsang ho kopanya mabanta a mabeli le ho sebelisa mocheso le khatello ho li kopanya hammoho. Mokhoa ona o fana ka motsoako o matla o ka mamellang meroalo e boima le tsitsipano.

Ts'ebetso e 'ngoe e tsebahalang ea manonyeletso a chesang ke mokhoa oa ho cheselletsa menoana, o sebelisang li-protrusions tse entsoeng ka mokhoa o khethehileng mabantang a lebanta ho etsa lenonyeletso le se nang moroallo. Mokhoa ona o fana ka phetoho e ntle haholo mme o fokotsa khatello ea maikutlo, e etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokang phetoho e boreleli ea lebanta.

Qetellong, ts'ebetso ea skiving e kenyelletsa ho tlosa karolo ea sekoahelo se ka holimo sa lebanta ka lehlakoreng le leng ebe o kopanya likarolo tse pepenene. Sena se etsa hore ho be le kopanelo e tlaase e fokotsang ho kena-kenana le li-pulleys kapa likarolo tse ling tse haufi le tsamaiso ea conveyor. E 'ngoe le e' ngoe ea mekhoa ena e chesang e kopanetsoeng e na le melemo ea eona 'me e khethoa ho latela litlhoko tse khethehileng tsa kopo le litlhoko tsa ts'ebetso.

Pele o reka: Fana ka tataiso ea litsebi ka ho fetisisa bakeng sa ho khetha lihlahisoa tse nepahetseng kapa tsamaiso ea litšebeletso.

Kamora ho reka: Warranty bakeng sa lilemo tse 1 kapa tse 2 joalo ka kopo le litlhoko tsa hau. Tšenyo leha e le efe e tla lokisoa kapa e nke sebaka se secha nakong ea tiisetso hafeela u sebelisa lihlahisoa e le mokhoa o nepahetseng le ho apara ho tloaelehileng ha lihlahisoa ntle le khefu leha e le efe ka mabaka a botho.

Kamora ho rekisoa: Kamehla fana ka litlhahiso tsa profeshenale bakeng sa maemo a sebetsang a lihlahisoa, fana ka tšehetso bakeng sa nts'etsopele ea ho bapatsa ea bareki ba khoebo ea mofuta oa hau. Kamehla lokisa ha feela re boloka tšebelisano.