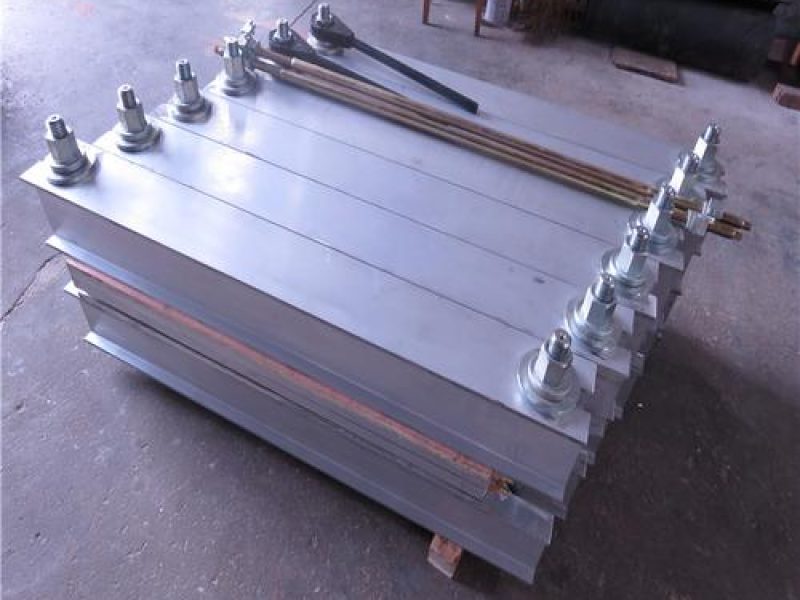

Rubber Conveyor Belt Hot Vulcanizing Press Machine

Suconvey Rubber kambani inopa emhando yepamusoro rabha conveyor bhandi rinopisa splicing vulcanizing press muchina. Muchina unopisa wekubatanidza bhandi remachira unonyanya kushandiswa kumaindasitiri ekubatanidza nekugadzirisa mabhandi ekutakurisa akadai sesimbi, mugodhi, simbi yemagetsi, chiteshi, doko, simende yekuvaka, indasitiri yemakemikari, fodya, uye chikafu otomatiki mutsara munda.

Hot Splicing Conveyor Bhandi Vulcanizing Press Machine

Key Features

- Machine Maximum saizi: kubva 300MM-6000MM;

- Voltage: 220V 380V 415V 660V 50HZ;

- Kukurumidza Kutonhora nguva: maminitsi gumi nemashanu (kubva pa15 degrees pasi kusvika ku145 degrees kana pasi);

- Nguva yekusimudza tembiricha (kubva kune yakajairika tembiricha kusvika kune inopisa tembiricha) isingapfuuri maminetsi makumi maviri nemashanu;

- Musiyano wetembiricha wepamusoro pe sulfide: ±2°c.

- Tembiricha inogadzirisa huwandu: 0 ~ 300 ° c.

- Vulcanizing pressure: 0 ~ 2.5 MPa (tsanangudzo inoreva kutsanangurwa kwevashandisi uye fekitori mamaki);

- Nguva yekuchengetedza kupisa kwevulcanizing inogona kugadziriswa maererano nehupamhi hwebhanhire rerubha;

- Kubatanidza kureba kwebhandi rekutakura rerabha rekubatanidza vulcanizing rinogona kubatanidzwa pamwechete nezvidimbu zvimwechete kana akati wandei kana zvichidikanwa;

- Rabha conveyor bhandi pamwe tension mukirogiramu inodiwa vulcanizing jointing kana kuhodha zvigadzirwa.

- Vashandisi vaigona kuodha mapombi emagetsi asara nekuwedzera zvichienderana nezvinodiwa.

Zvinotsanangurwa zveSuconvey Hot Vulcanizing Press Machine | ||||||

Order No. | Bhandi rakafara(mm) | chinhu(mm) | Ndiro yekudziya (mm) | Simba (kw) | Size (mamirimita) | Kurema (kg) |

SUH/LH-650 | 650 | 650 X 830 | 830 X 820 | 9.8 | 1080 X 165 X 170 | 470 |

650 X 1000 | 1000 X 820 | 11.8 | 540 | |||

SUH/LH-800 | 800 | 800 X 830 | 830 X 995 | 11.97 | 1250 X 165 X 170 | 635 |

800 X 1000 | 1000 X 995 | 14.4 | 735 | |||

SUH/LH-1000 | 1000 | 1000 X 830 | 830 X 1228 | 14.7 | 1450 X 165 X 170 | 865 |

1000 X 1000 | 1000 X 1228 | 17.8 | 955 | |||

SUH/LH-1200 | 1200 | 1200 X 830 | 830 X 1431 | 17.2 | 1680 X 165 X 250 | 965 |

1200 X 1000 | 1000 X 1431 | 20.7 | 1150 | |||

SUH/LH-1400 | 1400 | 1400 X 830 | 830 X 1653 | 19.8 | 1900 X 165 X 250 | 1160 |

1400 X 1000 | 1000 X 1653 | 23.8 | 1460 | |||

SUH/LH-1600 | 1600 | 1600 X 830 | 830 X 1867 | 22.3 | 2140 X 165 X 270 | 1320 |

1600 X 1000 | 1000 X 1867 | 27 | 1570 | |||

SUH/LH-1800 | 1800 | 1800 X 830 | 830 X 2079 | 24.9 | 2350 X 165 X 320 | 1480 |

1800 X 1000 | 1000 X 2079 | 30 | 1850 | |||

SUH/LH-2000 | 2000 | 2000 X 830 | 830 X 2303 | 27.6 | 2550 X 165 X 360 | 1530 |

2000 X 1000 | 1000 X 2303 | 33.2 | 1900 | |||

SUH/LH-2200 | 2200 | 2200 X 830 | 830 X 2478 | 29.7 | 2750 X 165 X 360 | 1700 |

2200 X 1000 | 1000 X 2478 | 35.8 | 2000 | |||

SUH/LH-2400 | 2400 | 2400 X 830 | 830 X 2678 | 31.8 | 2940 X 165 X 360 | 1850 |

2400 X 1000 | 1000 X 2678 | 38.9 | 2200 | |||

Inogadziriswa Inopisa Vulcanizing Machine Applications

- 8 makore ekugadzira ruzivo

- High Quality

- After-sales support services

- Standard uye Strict Dimension

Fabric Conveyor Belt

Adjustable Hot Splicing Belt Machine

Steel Cord Conveyor Belt

chiedza Hot Vulcanizing Belt Machine

Naironi Conveyor Bhandi

Portable Hot Joint Belt Machine

Hauzive Chekutanga Nei?

Wana Mhinduro YeProjekti Yako

Nezve Kambani

taura nesu

Suconvey Wholesale Inogona Kuve Nyore & Yakachengeteka.

Hazvina mhosva kuti rudzii rwemushini webhandi unopisa unopisa waunoda, zvichienderana neruzivo rwedu rwakakura, tinogona kugadzira nekukupa iwe.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- Ronglichang Industrial Park, Nhamba 4 Zijing Road, Longgang District, Shenzhen City

- Stephanie

- 86-13246961981

- [email inodzivirirwa]

Kubvunza Kwemahara

Tora mutengo wemahara

Pamusoro peSUCONVEY

Vatungamiriri MuHot Splicing Machine

Muchina weSUH wemvura wakatonhodzwa wevulcanizing wakashongedzerwa nemudziyo wekupodza mvura wekutenderera. Iyo yekudziya ndiro ine kukurumidza kutonhora kumhanya uye inogona kuparadzaniswa mu5-10 maminetsi. Kunyanya mumamiriro ekunze anopisa, tembiricha yakakwira uye nguva yekuvaka yakasimba, kushandiswa kweiyi mvura-yakatonhorera vulcanizing muchina kunogona kuvandudza kushanda zvakanaka uye kupfupisa nguva yekuvaka. Izvo zvikamu zveSUH mvura-yakatonhorera vulcanizing muchina zvakareruka uye zvinogona kufambiswa nevashandi. Usati waiswa, kuve nyore kwesimba uye zvitubu zvemvura zvinofanirwa kutariswa. Shandisa pombi yemvura yakakosha kubatanidza pombi yemvura kune pombi dzemvura dzinotonhodza dzepamusoro nedzepasi dzekudziisa dzemuchina wevulcanizing, asi usabvisa mvura panguva ino. Panguva ino, tembiricha yenguva dzose inotanga kusvika vulcanization yenguva dzose tembiricha nguva yapera. Panguva ino, vhura mvura yepombi uye upfuure mvura kune ndiro inopisa. Kana tembiricha inodonha kune iyo nzira yakatarwa kukosha Kana iyo midziyo yakagadzirira, mvura inogona kuburitswa kuti iparadzanise michina, uye vulcanization inoshanda inopedzwa.

Nezve Kambani

Mabhenefiti eHot Splicing

Michina yekupisa vulcanizing yemabhandi ekutakurisa inopa zvakati wandei zvakanakira izvo zvinovaita sarudzo yakasarudzika muindasitiri. Imwe yemabhenefiti akakosha ndeyemhando yepamusoro ye splice yavanopa. Iyo tembiricha yepamusoro uye kudzvanywa kunoshandiswa panguva inopisa vulcanization inovimbisa chisungo chakasimba uye chakasimba pakati pezvikamu zvebhandi, zvichikonzera kuvandudzwa kwese kwese kwekufambisa kuita uye hupenyu hurefu.

Pamusoro pezvo, michina yekupisa inopisa inogonesa kupatsanurana, kubvisa zvingangove zvisina simba mapoinzi kana mabulges anowanzo sangana nedzimwe nzira dzekubatanidza. Izvi hazvingoderedzi nguva yekudzikisira asi zvakare inowedzera kuchengetedzwa kwekushanda nekudzikisa njodzi yekutadza kusingatarisirwi kwebhandi. Uyezve, kupisa vulcanization kunobvumira kugadziridzwa kwezvigadziriso zve splice, kugovera kune chaiyo application zvinodiwa senge yakawedzera mutoro-inotakura simba kana kuramba kune abrasion, nekudaro ichiwedzera kuita kwakasiyana-siyana uye kuita kwemaconveyor masisitimu.

About Design

Nzira yekutenga sei inopisa vulcanizing muchina?

Yedu, Suconvey, yemhando yepamusoro uye yemhando yepamusoro inopisa vulcanizing michina ine mukurumbira muindasitiri nekusimba kwayo, kushanda nesimba, uye tekinoroji yepamusoro. Tiine tarisiro yekuenderera mberi kwekuvandudza uye kugutsikana kwevatengi, takazvimisa semutambi akakosha pamusika.

Usati waisa odha imwe, ndapota simbisa

- Conveyor bhandi upamhi;

- Splice urefu;

- Bias Angle;

- Vulcanization pressure.

- Voltage

About Kuchengeta

Maitiro ekuchengetedza vulcanizing muchina

Kuchengeta uye kushandisa muchina unopisa wevulcanizing kwakakosha kuti uve nechokwadi chekugara kwenguva refu uye kushanda zvakanaka kwerabha conveyor bhandi masisitimu.

Kugara uchiongorora zvinhu zvekudziya zvemuchina, masisitimu ekumanikidza, uye zvinodzora tembiricha zvakakosha kuti uone chero zvingangoitika zvisati zvakwira.

Pamusoro pezvo, kuchengetedza kurongeka kwakaringana kwemabhandi ekutakura panguva yevulcanization kwakakosha pakuwana yunifomu yekugovera kupisa uye kusimba kwekubatana. Izvo zvakakoshawo kutevedzera mugadziri-anokurudzirwa ekugadzirisa masheti ekutsiva ekudziya zvinhu, kudzvanya zvikamu, uye tembiricha sensors kuve nechokwadi chekushanda kwakakwana.

Uyezve, vashandisi vanofanirwa kuve vakadzidziswa mukushandisa muchina unopisa wekudzivirira kudzivirira kusakara uye kubvarura pazvinhu zvakakosha. Izvi zvinosanganisira kunzwisisa nzira dzekugadzirira bhandi dzakaringana, tembiricha inokurudzirwa yevulcanizing, uye nzira dzekushandisa dzemhando dzakasiyana dzemabhandi ekutakurisa rabha. Kuita maitiro ekugadzirisa ekugadzirisa hakuzongowedzera hupenyu hwesevhisi yemuchina wekupisa vulcanizing asi zvakare kubatsira mukuvandudza chibereko uye kudzikisira nguva mukushanda kwebhandi rekutakura.

FAQ

Yakawanda mibvunzo uye mhinduro

bvunza mumwe mubvunzo

Iyo inopisa yakabatana maitiro emabhandi ekutakurisa chinhu chakakosha chekuchengetedza nekugadzirisa izvi zvakakosha maindasitiri. Iyi nzira inosanganisira kushandiswa kwekupisa uye kumanikidza kubatanidza migumo miviri yebhandi rekutakura pamwe chete, kuve nechokwadi chekubatana kwakasimba uye kwakasimba. Kana ichinge yaitwa nemazvo, kupisa kwakabatana muitiro kunoguma nekubatanidzwa kusina musono, zvichibvumira bhandi rekutakura kuti rishande zvakanaka pasina njodzi yekuparadzana kana kutadza. Iyo inzira ine hunyanzvi inoda kunyatsojeka uye hunyanzvi kuti uwane mhedzisiro yakakwana.

Chimwe chinhu chinokosha muhutano hwekupisa hunopisa ndiko kusarudzwa kwezvinhu zvakakodzera uye zvinonamatira. Rudzi rwerubha musanganiswa, jira, uye rinonamira rinoshandiswa rinogona kukanganisa zvakanyanya kusimba uye hupenyu hurefu hwejoini. Uyezve, chaiyo tembiricha yekudzora panguva yekudziya inoita basa rakakosha mukuona kuti zvinhu zvinosungirirana zvakanaka pasina kukonzeresa kukuvadza kana kupera simba kweiyo conveyor bhandi chimiro. Kunzwisisa zvinhu izvi kwakakosha kuti uwane majoini anopisa anovimbika anoshingirira kuomarara kwekuenderera mberi kwekushanda munzvimbo dzakasiyana dzeindasitiri.

Mukupedzisa, kugona kupisa kwakabatana maitiro kwakakosha kune maindasitiri anovimba nemaconveyor masisitimu kuti achengetedze mashandiro akanaka. Nekunzwisisa kuomarara kwayo uye nekudyara muzvinhu zvemhando yepamusoro uye vashandi vane hunyanzvi, mabhizinesi anogona kuve nehupenyu hurefu hwesevhisi kumabhandi avo ekutakura uku achideredza nguva yekudzikira nekuda kwekugadzirisa kana kutsiva. Sezvo tekinoroji ichienderera mberi, zvakakosha kuti nyanzvi mune ino ndima kuti vagare vaine ruzivo nezve hunyanzvi hutsva uye hutsva hunogona kuwedzera chinhu chakakosha ichi chekuchengetedza bhandi rekutakura.

Kune akati wandei emhando dzekupisa dzemajoini maitiro anoshandiswa kune mabhandi ekutakurisa, rimwe nerimwe riine maitiro akasiyana uye mabhenefiti. Rudzi rwekutanga ndeye kupindirana kwewelding process, iyo inosanganisira kupindirana mativi maviri ebhandi uye kushandisa kupisa uye kumanikidza kuabatanidza pamwechete. Iyi nzira inopa hukama hwakasimba hunogona kumira mitoro inorema uye kunetseka.

Imwe nzira yakakurumbira yekupisa yekubatanidza ndeye minwe-inopindirana welding nzira, iyo inoshandisa yakagadziridzwa minwe-yakafanana protrusions pabhandi inopera kugadzira mubatanidzwa usina musono. Iyi nzira inopa yakanakisa kuchinjika uye inoderedza kushushikana, ichiita kuti ive yakakodzera kune maapplication anoda yakatsetseka bhandi shanduko.

Chekupedzisira, iyo skiving process inosanganisira kubvisa chikamu chebhanhire chepamusoro chivharo pamakona uye wozosunga zvidimbu zvakafumurwa. Izvi zvinoguma mune yakaderera-mbiri yakabatana iyo inoderedza kukanganiswa nemapulleys kana zvimwe zvikamu pamwe neiyo conveyor system. Imwe neimwe yeaya anopisa akabatanidzwa maitiro ane zvayakanakira uye anosarudzwa zvichibva pane chaiyo application zvinodiwa uye mashandiro ekuita.

Usati watenga: Ipa iyo yakanyanya hunyanzvi gwara rekusarudza zvigadzirwa zvakanaka kana sevhisi system.

Mushure mekutenga: Warranty ye1 kana 2 makore sekushandisa uye zvaunoda. Chero kukuvadzwa kuchave kugadzirisa kana kutsiva kutsva panguva yewaranti chero bedzi uchishandisa zvigadzirwa senzira chaiyo uye yakajairwa kupfeka kwezvigadzirwa kunze kwekuzorora chero nezvikonzero zvemunhu.

Mushure mekutengesa: Gara uchipa mazano ehunyanzvi ezvigadzirwa zvinoshanda chimiro, ipa rutsigiro kune vatengi kushambadzira kuvandudza kweiyo brand bhizinesi. Gara uchigadzirisa chero bedzi tichichengeta kubatana.