Medical Grade Silicone Sheeting

Medical Grade Silicone Sheet Supplier

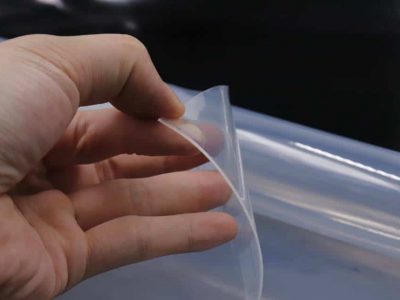

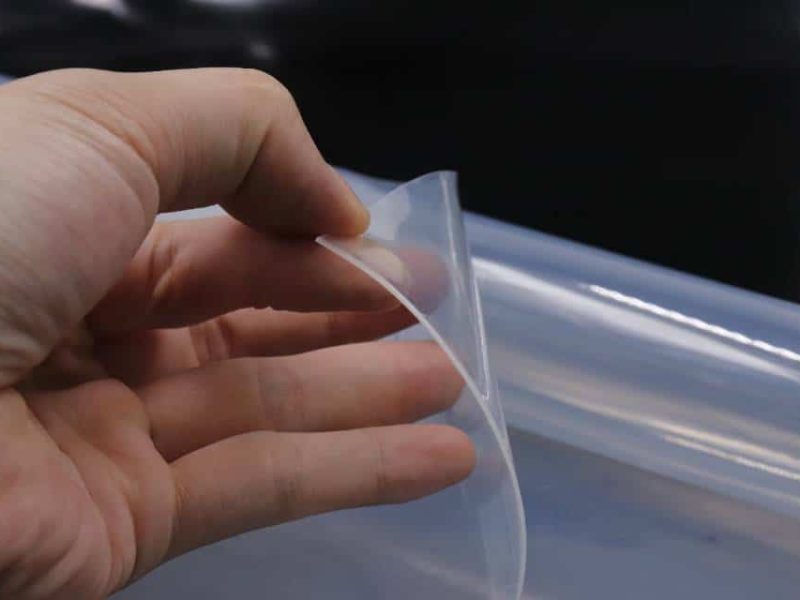

Our medical grade silicone sheets are manufactured using high-purity platinum-cured silicone elastomers designed for safe contact with the human body. The material is chemically inert, transparent in appearance, and suitable for applications that require reliable biocompatibility and long-term stability.

Key Features

- Manufactured from platinum-cured medical silicone

- Chemically inert and non-reactive

- Odorless and non-toxic

- Resistant to cleaning chemicals, ozone, and UV exposure

- Suitable for continuous use across a wide temperature range

- Excellent flexibility and tear strength for demanding applications

- Available as sheets, rolls, or custom-cut components

Medical Approved Silicone Sheet

Our platinum-cured silicone sheets are formulated for medical device integration, offering high purity, low extractables, and excellent thermal and mechanical stability.

Compliant with USP Class VI and ISO 10993 biological evaluation standards, the material maintains performance through autoclave, gamma, and ETO sterilization cycles.

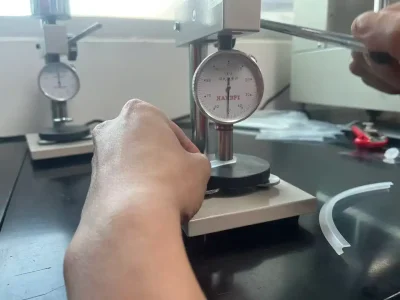

Mechanical data, extractables profiles, and compression set results are available upon request for engineering qualification.

Product Details

China Medical Grade Silicone Rubber Sheet Manufacturer

Medical Grade Silicone Sheet Technical Specifications

| Parameter | Value |

|---|---|

| Material | Medical grade silicone |

| Hardness | 30A – 80A |

| Thickness | 0.3 mm – 10 mm |

| Width | Up to 1,000 mm |

| Temperature Range | −60°C to +230°C |

| Color | Translucent or custom |

| Surface | Smooth / Matte / Textured |

| Compliance | USP Class VI / ISO 10993 / FDA / RoHS / REACH |

Medical Grade Silicone Rubber Sheet For sale

Our Customization & Conversion

To suit equipment and device integration, custom formatting is available:

- Die-cutting and laser cutting

- Slitting and strip cutting

- Punching and perforation

- OEM branding and private labeling

Custom formulations can also be engineered for:

- Higher tear resistance

- Lower compression set

- Controlled friction surfaces

- Long-term thermal endurance

Main Applications of Medical Grade Silicone Sheet

Medical grade silicone sheets are used in situations where contact safety, flexibility, and stability are critical. Typical applications include:

---Medical & Healthcare

- Seals and gaskets for medical devices

- Isolation and cushioning pads

- Valves, diaphragms, and pump components

- Orthopedic liners and pressure pads

- Diagnostic equipment dampers

---Laboratory & Life Sciences

- Silicone cover sheets for thermal systems

- Instrument insulation and gasketing

- Transfer surfaces for analytical equipment

---Clean & Controlled Environments

- Use in cleanrooms or sterilization cycles where materials must not degrade or shed particulates

Sterilization Compatibility

Medical silicone can withstand repeated sterilization cycles without physical or chemical degradation. Compatible methods include:

- Autoclave steam

- Gamma irradiation

- ETO sterilization

- Dry heat

- Chemical disinfectants

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Medical grade silicone refers to materials that demonstrate safe biological interaction and comply with relevant biocompatibility standards. Our sheets are made from platinum-cured silicone that has been tested to USP Class VI and ISO 10993 biological evaluation standards.

Yes. Medical grade silicone is chemically inert and non-reactive, and is commonly used in devices that contact human skin or tissue. Please share your intended application so we can verify the correct compliance documentation for your region or device class.

The standard range is 0.3–20 mm in thickness and 30A–80A in Shore hardness. Custom thicknesses or special hardness values can be produced for OEM applications.

Yes. We offer die-cutting, laser cutting, slitting, punching, adhesive backing, and OEM part numbering to support device integration and assembly workflows.

Standard items have low MOQs starting from 1–2 rolls with typical lead times of 7–15 days. Custom items are based on total square meters and processing requirements.

Applications include:

- Medical device manufacturing

- Laboratory equipment

- Healthcare accessories

- Cleanroom applications

- Diagnostic instruments

- Orthopedics and rehabilitation hardware