Flame Retardant Silicone Foam Sheet (Fire-Resistant Silicone Sponge)

UL 94 V-0 Silicone Foam Sheets Supplier

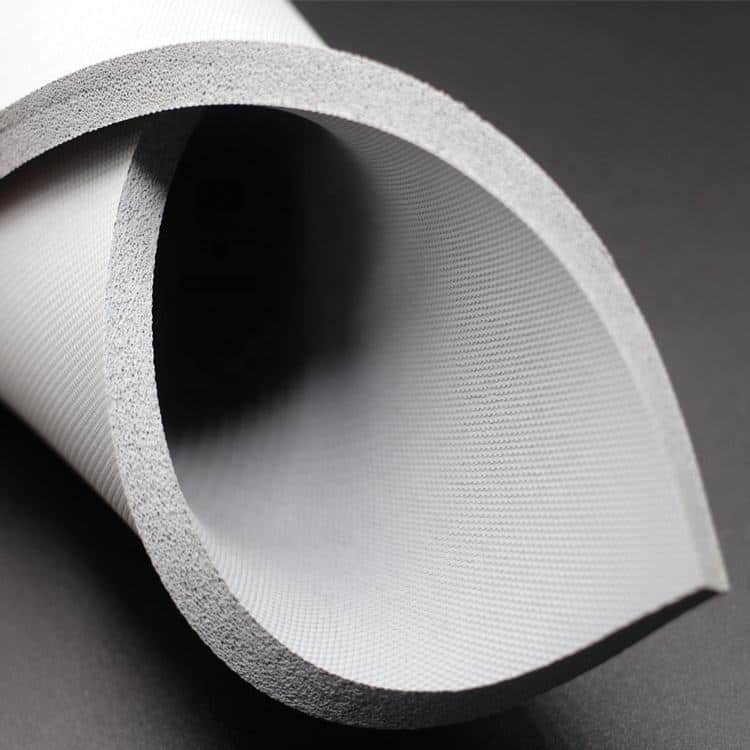

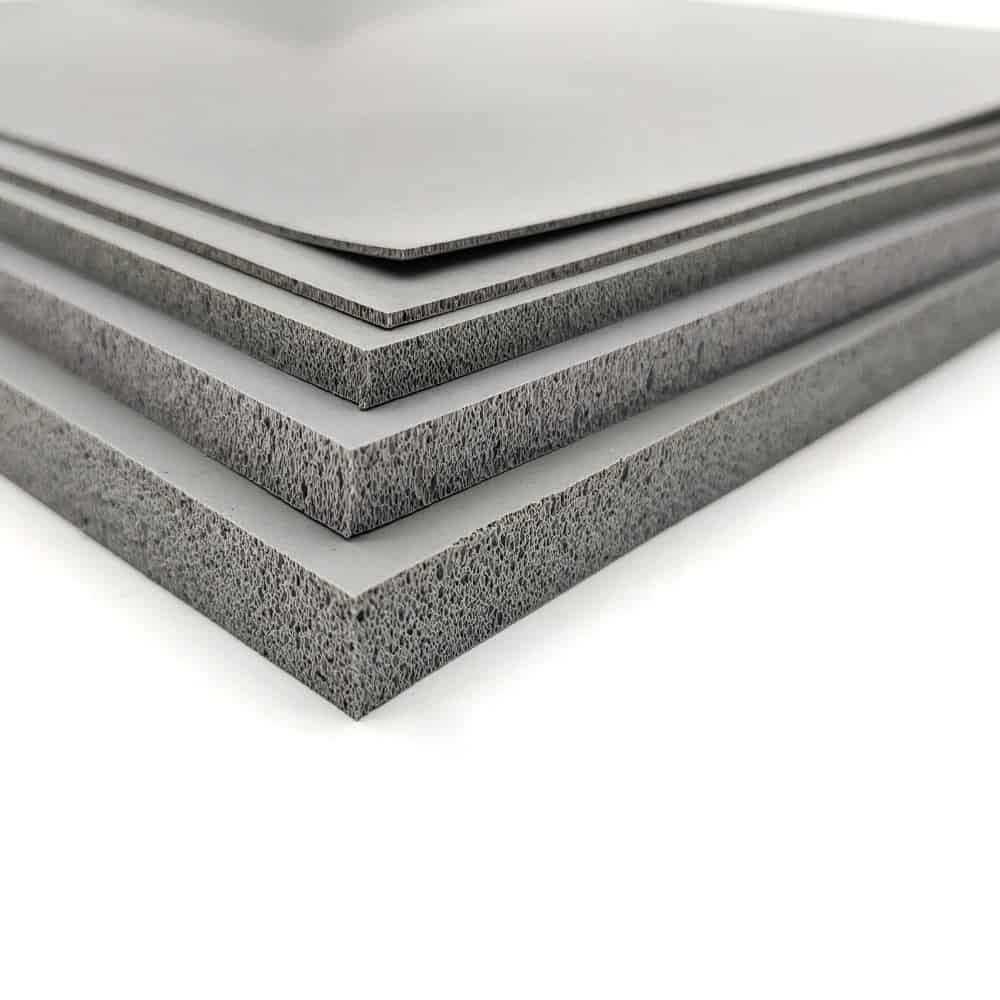

Flame retardant silicone foam sheets are engineered cellular elastomers designed to provide both thermal insulation and fire resistance for demanding environments.

These materials combine the high temperature tolerance of silicone with enhanced flame retardant properties that comply with common safety standards, making them suitable for electrical cabinets, appliances, transportation, battery, rail interiors, aerospace components and industrial enclosures where fire performance is critical.

Flame retardant silicone foam sheets can be designed to meet multiple fire and safety standards depending on application:

- UL 94 V-0 / VTM-0 – Vertical burn and flame tests for plastics and foams

- FMVSS 302 – U.S. automotive interior flammability

- EN 45545-2 – Railway fire safety standard

- NFPA 130 / NFPA 701 – Transit and textile flammability

- ASTM E84 (Class A/B) – Surface burning characteristics

- IEC 60695 – Fire hazard testing for electrical components

UL94 V-0 Approved Flame Resistant Silicone Sponge Sheet

Flame retardant silicone foam is a specially formulated variant of silicone sponge that incorporates fire-resistant chemistry and additives. Unlike standard silicone foam, which primarily focuses on thermal resistance and compression sealing, flame retardant silicone foam is optimized to resist ignition, self-extinguish once the source is removed, and minimize flame spread and smoke generation.

This makes it the preferred solution for installations where regulatory fire performance is required.

Product Details

Fire Resistant Silicone Sponge Sheet Rolls Supplier

Key Features

- Thermal stability — continuous resistance up to 180–200 °C

- Chemical inertness — resistant to ozone, weather and aging

- Electrical insulation — non-conductive, ideal for electrical cabinets

- Ignition resistance

- Self-extinguishing behavior

- Minimal flame spread

- Low smoke generation

- Reduced toxic gas output

- Compression cushioning

- Gap tolerance absorption

- Dimensional stability

- Low compression set

- Resilience after repeated compression cycles

China Flame Resistant Silicone Foam Sheet Manufacturer

Fire Resisant Silicone Sheet Technical Specifications

| Property | Typical Range |

|---|---|

| Material | Flame retardant silicone foam |

| Cell Structure | Closed-cell or semi-closed-cell |

| Continuous Temperature | 180–200℃ |

| Peak Temperature | Up to 250℃ (application dependent) |

| Density | Soft, medium and firm grades |

| Compression Set | Low, suitable for long-term sealing |

| Compression Force Deflection (CFD) | Grade-dependent, designed for enclosure and panel sealing |

| Thermal Insulation | Moderate |

| Flame Rating | UL 94 V-0 / EN 45545-2, depending on grade |

| Smoke / Toxicity | Low, based on tested formulation |

| Electrical Properties | Good electrical insulation |

Typical Applications of Fire resistant Silicone Sheets

Electrical and Electronic Enclosures

Used for:

- Control panel gasketing

- Switchgear cabinet doors

- Relay and distribution boxes

- Power supply housings

Transportation and Transit Interiors

Common in:

- Rail car interiors (EN 45545-2)

- Bus and coach door seals

- Aircraft cabin components

- Marine vessel compartments

HVAC and Building Systems

Used for:

- HVAC access panels

- Duct gasketing in public buildings

- Fire partition seals

- Elevator and stairwell door interfaces

Appliances and Industrial Equipment

Examples:

- Oven and furnace access panel seals

- Thermal processing seals

- Automotive battery packs with fire containment barriers

- Industrial cabinets requiring NFPA/UL compliance

Best Choice for Your UL 94 Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for platinum-cured silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---OEM & Branding Service

We support OEM cooperation for equipment manufacturers and distributors. Products can be supplied under your brand, part code, or specification. Lot numbers and QC labels can be printed for traceability if required.

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

---Quality Assurance

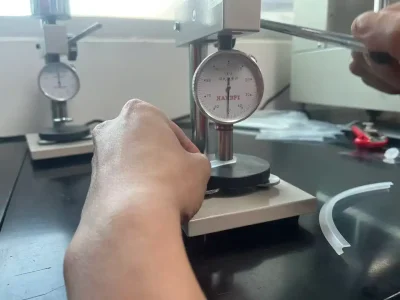

Each batch undergoes hardness, thickness, and visual checks with recorded batch data for traceability. Compliance with food-contact regulations is verified through third-party laboratory testing when required by the customer.

How Flame Retardant Silicone Foam Compares to Other Materials

| Material | Flame Performance | Thermal Insulation | Environmental Sealing | Typical Use |

|---|---|---|---|---|

| Silicone Foam (Standard) | Limited | Moderate | Good | General insulation and cushioning |

| Flame Retardant Silicone Foam | Excellent (V-0 / EN 45545, etc.) | Moderate | Good | Safety-critical sealing and insulation |

| EPDM Foam | Poor | Moderate | Good | Low temperature, non-fire-rated zones |

| Polyurethane Foam | Poor | High | Limited | Low temperature, non-regulated insulation |

| PTFE | Non-flammable | Moderate | Excellent | Electrical insulation and chemical resistance |

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

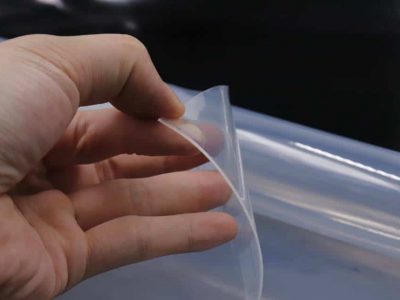

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Quotations typically require:

- Target flame standard (UL 94 / EN 45545 / FMVSS 302 etc.)

- Thickness and density

- Format (sheet, roll, strip, kiss-cut, gasket)

- Dimensions or drawings (DXF/DWG/PDF acceptable)

- Required adhesive backing (if any)

- Estimated annual volume / order quantities

- Delivery terms and destination country

- Providing regulatory standards up front significantly reduces back-and-forth in quotation.

Flame retardant silicone foam should be specified when the installation is subject to regulatory fire performance requirements such as UL 94, EN 45545-2, FMVSS 302 or building fire codes. This applies to electrical cabinets, rolling stock interiors, appliance housings and battery modules where ignition resistance and self-extinguishing behavior are safety-critical. Standard silicone foam is suitable for non-regulated insulation and general enclosure sealing.

Yes. Flame retardant silicone foam offers both insulation and compression sealing. The cellular structure provides thermal isolation, while controlled compression force deflection enables environmental sealing against dust, air and moisture when the gasket is clamped between panels or doors.

Not directly. Flame retardant silicone foam improves ignition resistance and self-extinguishing behavior but does not expand to form a char barrier like intumescent materials. For fire containment or structural fire barriers, intumescent or ceramic fiber materials may be required.

Yes. Silicone foam gaskets can be provided with pressure-sensitive adhesive on one or both sides and kiss-cut on liners to support automated or manual assembly. Adhesive type should be selected according to substrate material and service temperature.

Yes. Silicone provides excellent UV, ozone and weathering resistance, making it suitable for outdoor cabinets and infrastructure installations. This differentiates it from polyurethane foams, which degrade quickly under UV exposure.