Fiberglass Reinforced Silicone Rubber Sheet Manufacturer

Fiberglass Reinforced Silicone Press Pad for Solar Module Lamination

Suconvey Rubber manufactures fiberglass reinforced silicone rubber sheet rolls for demanding press pad, heat sealing and gasket applications.

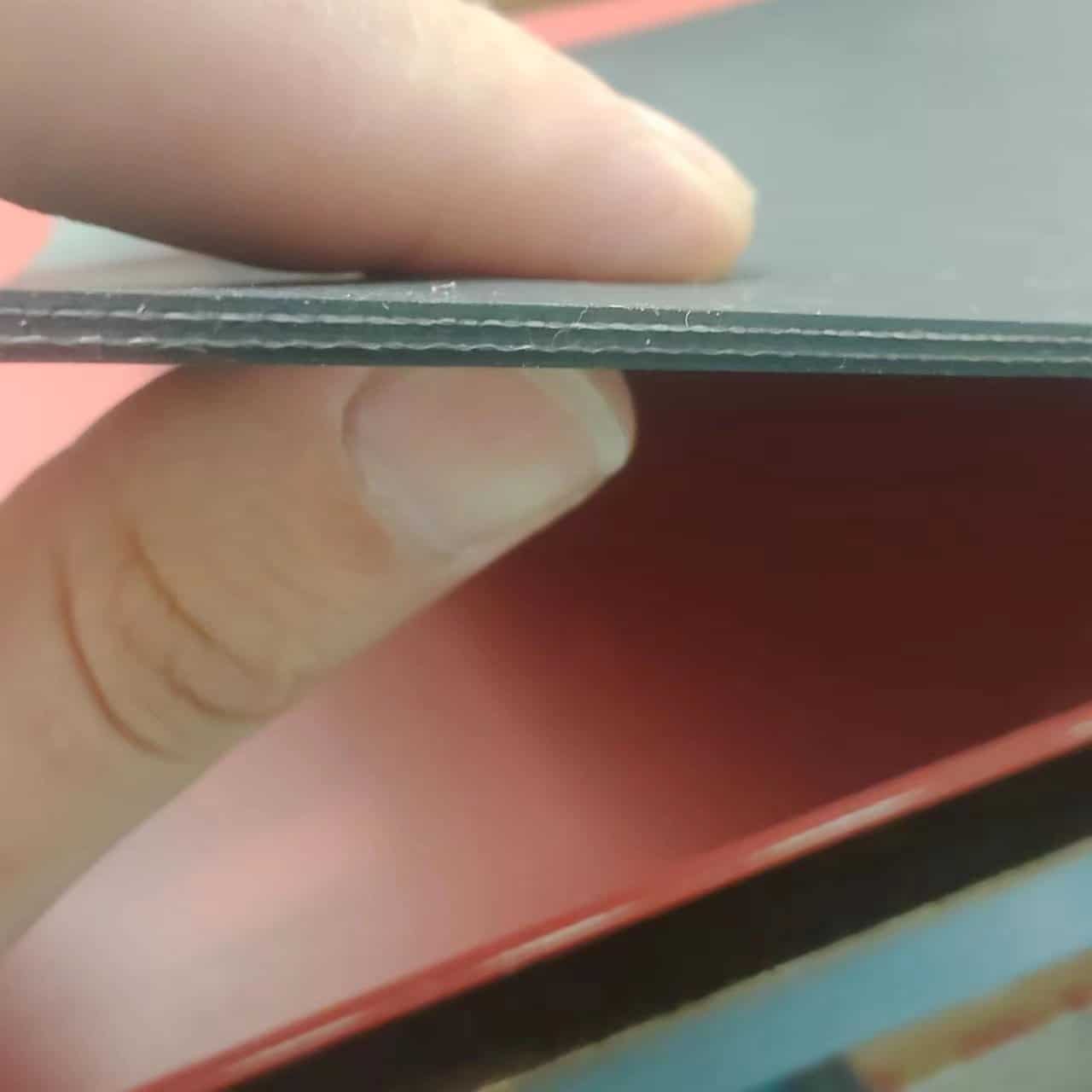

A woven fiberglass fabric is embedded inside the silicone to provide zero-stretch dimensional stability and high tear strength, while the outer silicone layers deliver excellent temperature and chemical resistance.

Compared with standard solid silicone sheet, our fiberglass reinforced grade is designed for high pressure, high cycle and tight tolerance environments where ordinary elastomers quickly deform or creep.

What Is Fiberglass Reinforced Silicone Sheet?

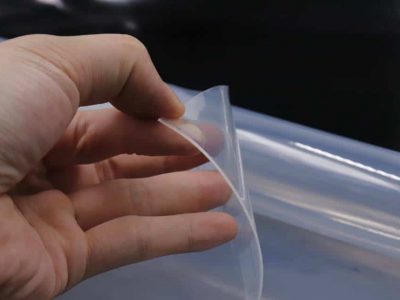

Fiberglass reinforced silicone sheet is a multi-layer composite made by laminating a fiberglass fabric core between two layers of silicone rubber.

- The fiberglass insert works like an internal skeleton, controlling stretch, shrinkage and warping under load.

- The silicone skins provide a non-porous, heat-resistant and weather-resistant surface that seals reliably against metal, glass or composite parts.

This structure combines the elasticity of silicone with the dimensional stability of an engineering fabric, making it ideal for press pads, diaphragms, flange gaskets and other components that must maintain thickness and shape over millions of cycles.

Product Details

Solar Module Laminator Silicone Sheet Rolls Supplier

Key Features

- High tensile strength & tear resistance – fiberglass fabric dramatically improves mechanical strength and resistance to tearing at bolt holes and cut-outs.

- Dimensional stability, low stretch – internal fabric controls elongation and shrinkage for precise gasket and press pad thickness.

- Excellent compression set resistance – maintains thickness and sealing force after repeated compression, ideal for clamps and bolted joints.

- Wide temperature range – typical working range from -60°C to +230°C, with short peaks up to +250°C depending on compound grade.

- Weather, ozone & UV resistant – silicone rubber is inherently stable outdoors and in ozone rich environments.

- Good chemical resistance – resists many oils, solvents, coolants and cleaning agents commonly used in industrial equipment.

- Smooth or fabric finish – choose from smooth surface for sealing or textured fabric finish for friction and grip.

- Long Service Life – extended cycle life reduces line downtime, Over 50,000 Life Cycles

China PV Module Silicone Rubber Sheet Manufacturer

Technical Specifications

| Base Material | Silicone rubber (VMQ) with fiberglass fabric insert |

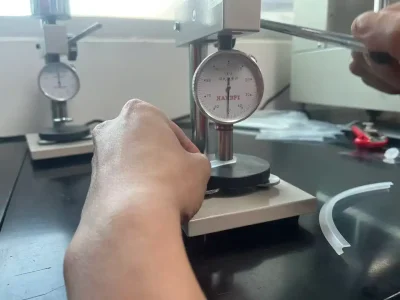

| Hardness | 60-80 Shore A |

| Width | Up to 3500mm |

| Specific Gravity | 1.20–1.35 g/cm³ |

| Tensile Strength | Up to 13 MPa |

| Elongation at Break | 450% |

| Tear Strength | 45 N/mm |

| Compression Set | Excellent, suitable for repeated clamping |

| Continuous Service Temperature | -60°C to +230°C |

| Short Peak Temperature | Up to +250°C (application dependent) |

| Flame Rating | UL 94 V-0 grade available on request |

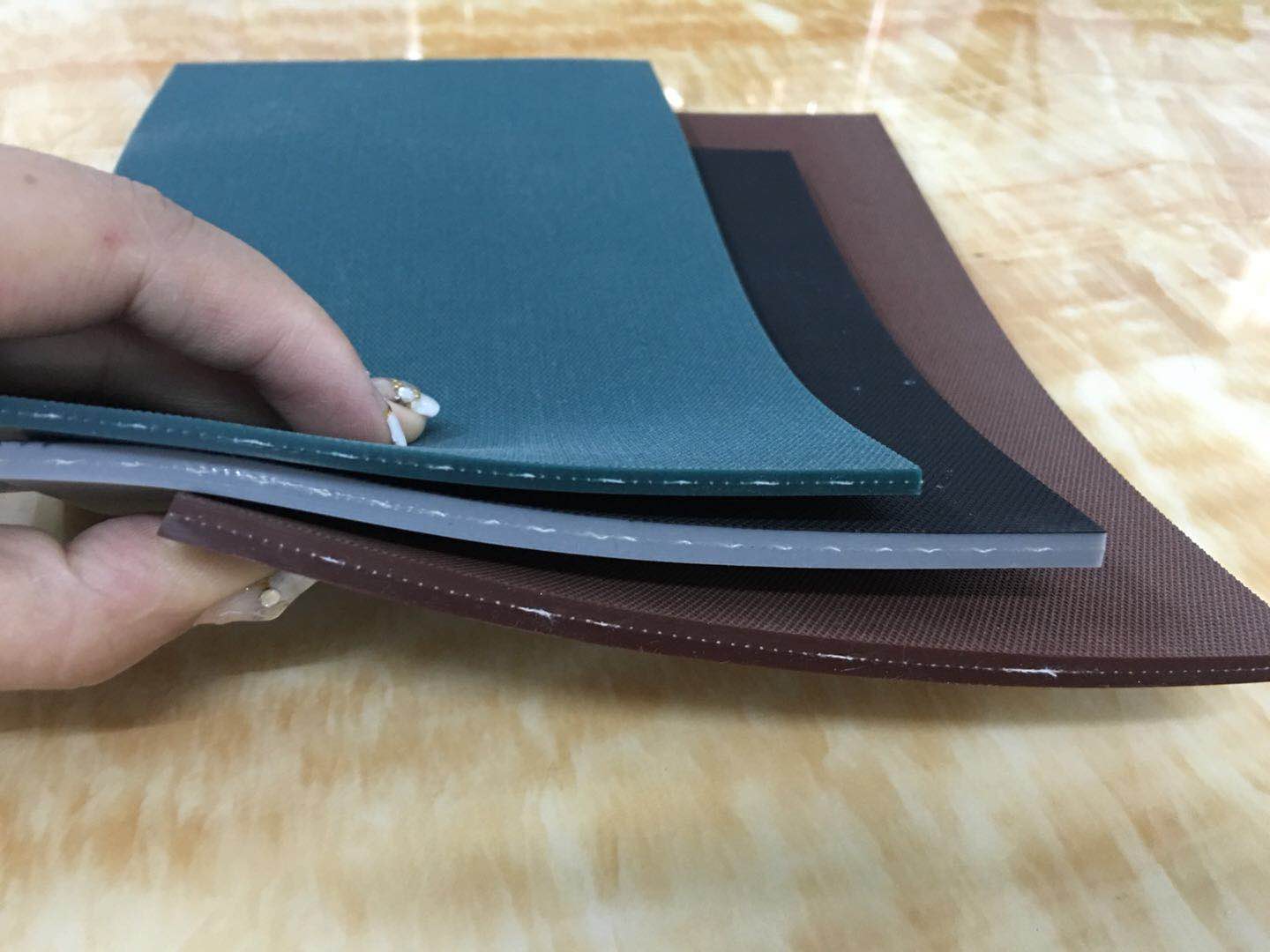

| Color | Brick red, grey, black, white or customized |

| Surface Finish | Smooth / fabric pattern / custom |

| Available Forms | Continuous rolls, sheets, and CNC / water-jet cut gaskets |

Fiberglass Reinforced vs. Standard Silicone Sheet

| Feature | Fiberglass Reinforced Silicone Sheet | Standard Solid Silicone Sheet |

|---|---|---|

| Dimensional Stability | Excellent – fabric insert controls stretch and shrinkage | Moderate – can stretch or creep under long-term load |

| Tear Strength at Cut-outs | Very high, ideal for bolted gaskets | Lower, more sensitive to tearing around holes |

| Compression Set Resistance | Very good, maintains thickness over repeated cycles | Good, but more tendency to take a permanent set |

| Flexibility | Stiffer due to fiberglass core | Softer and more flexible |

| Best Use | Press pads, structural gaskets, non-stretch strips | General-purpose seals, cushioning, insulation |

| Adhesive Backing | Available, recommended for non-stretch mounting | Available |

Best Choice for Your Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---OEM & Branding Service

We support OEM cooperation for equipment manufacturers and distributors. Products can be supplied under your brand, part code, or specification. Lot numbers and QC labels can be printed for traceability if required.

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

Core Function in Solar Lamination Equipment

During solar panel manufacturing, glass, solar cells, EVA/POE encapsulants and the backsheet must be laminated together in a vacuum laminator. Thickness variations between layers require a compressible and dimensionally stable press pad to achieve uniform contact pressure.

The fiberglass reinforced silicone sheet works as a wear layer / diaphragm inside the laminator:

- compensates thickness variations between cell strings

- maintains pressure uniformity across the glass surface

- protects the vacuum laminator membrane

- improves encapsulation quality and bubble elimination

- withstands repeated thermal cycles without shrinkage

As a result, module manufacturers experience:

- Fewer bubbles & voids

- Improved EVA wetting & layer bonding

- Reduced module scrap rate

- More consistent optical appearance

- Longer equipment membrane life

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Certainly. We offer CNC and water-jet cutting, as well as precision slitting for strips. You can send us DXF / DWG files or physical samples, and we will quote based on the finished parts.

For standard sizes and colors, we support relatively low MOQs to help you start new projects or replacement programs. For custom formulations or special fabric constructions, the MOQ will be higher – please contact us for details.

Sample pieces and small trial orders are typically dispatched within 5–7 working days. Bulk production orders usually ship in 2–3 weeks, depending on quantity and customization level.

Because pure silicone creeps under heat and vacuum, causing pressure non-uniformity and bubbles. Fiberglass reinforcement prevents stretch and improves encapsulation consistency.

Replacement cycles vary by encapsulant, temperature and laminator setup. Typical ranges are 50,000–100,000 cycles for reinforced silicone pads, depending on EVA/POE chemistry.