Custom Silicone Rubber Sheet Roll

Custom Silicone Sheet Roll Manufacturer

Suconvey is a professional manufacturer of custom silicone rubber sheet rolls in China.

We help OEMs, equipment builders and distributors get the exact silicone sheet they need – with the right thickness, color, hardness, surface finish and performance grade, from general industrial to food and medical.

With short lead times, flexible minimum order quantities and one-to-one engineering support, we work to remove the headaches from your silicone sheet sourcing process.

Customize Silicone Rubber Sheet Rolls for Your Application

Custom silicone rubber sheet is ideal when standard stock sheets cannot meet your size, color, hardness or performance requirements.

At Suconvey you can customize:

- Thickness: from ultra-thin membranes to heavy duty pads

- Width & length: narrow strips, standard rolls or extra wide sheets

- Hardness: soft cushioning grades to high-durometer structural grades

- Color: clear, translucent, or any Pantone color you require

- Grade: industrial, food grade (FDA) or medical grade

- Reinforcement: with fabric or canvas insert layers

- Surface: smooth, wave (textured) or matte finish

- Adhesive backing: with 3M or brush-applied glue on one side

Tell us your application and basic requirements, and our team will recommend a suitable silicone formulation and construction.

Product Details

Customizable Silicone Sheet Rolls Supplier

Key Features

- High strength & tear resistance – stable mechanical performance with tear strength up to 25 MPa (depending on grade).

- Wide temperature range – typical working range from −60°C to +300°C, suitable for high and low temperature environments.

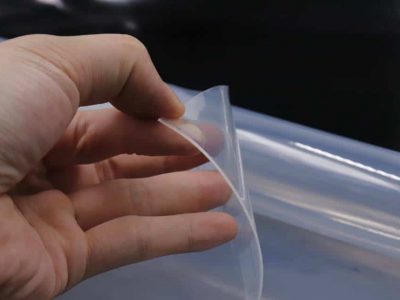

- Flexible & soft surface – excellent flexibility, cushioning and low friction, easy to handle and install.

- Excellent durability – resistant to aging, ozone, UV, weathering and many chemicals.

- Slip-resistant surface – good anti-slip performance for lining and contact surfaces.

- Food & medical capable – food grade and medical grade silicone available, with FDA and halogen test approvals.

- Multiple density options – from solid silicone sheet to sponge grades with very low density.

China Custom Silicone Rubber Sheet Rolls Manufacturer

Technical Specifications

| Thickness | 0.1 mm – 20 mm |

| Width | 1 mm – 3,500 mm |

| Length | Custom (cut-to-length or rolls) |

| Specific Gravity | 0.2 g/cm³ – 1.3 g/cm³ (solid or sponge) |

| Color | Pantone colors and transparent options |

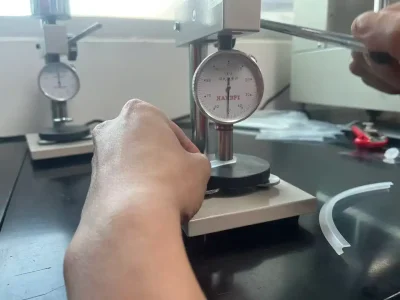

| Hardness | 5 – 90 Shore A |

| Appearance | Smooth / Wave / Matte |

| Temperature Range | −60℃ to +300℃ (grade dependent) |

| Tear Strength | Up to 25 MPa |

| Elongation at Break | 300 – 650% |

| Compression Set / Deformation Rate | ≤ 9% (typical values) |

| Flammability | UL 94 V-0 on request |

| Acid and Alkali Resistance | Available for selected grades |

| Insert Layer | Fabric or canvas reinforcement |

| Adhesive / Stick Layer | 3M adhesive or brush-applied glue |

| Food Grade | FDA approved silicone available |

| Medical Grade | Passed halogen test |

| Water Absorption | 0% for solid silicone, approx. 80% for sponge |

| Aging Period | Up to 3 years under proper storage conditions |

| Chemical Safety | RoHS and SVHC compliant |

Best Choice for Your Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---OEM & Branding Service

We support OEM cooperation for equipment manufacturers and distributors. Products can be supplied under your brand, part code, or specification. Lot numbers and QC labels can be printed for traceability if required.

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

---Quality Assurance

Each batch undergoes hardness, thickness, and visual checks with recorded batch data for traceability. Compliance with food-contact regulations is verified through third-party laboratory testing when required by the customer.

Our Custom Service Capabilities

We do more than just standard rolls – Suconvey offers a full range of fabrication and support services:

- Cut to size sheets and pads according to your drawing

- Slitting into strips and narrow rolls

- Backed adhesive available – laminating 3M or other PSA systems

- Insert layers – fabric or canvas reinforcement for dimensional stability

- Free samples and design drawings for new projects

- Engineering support – help you choose the right silicone grade, hardness and thickness for your equipment

Whether you need a single prototype or a long-term OEM supply program, we can tailor our service to your requirements.

| Color | Hardness (Shore A) | Typical Thickness Range |

|---|---|---|

| Transparent | 20 | 0.1 mm – 8 mm |

| Translucent | 25 | 0.2 mm – 9 mm |

| Red | 30 | 0.5 mm – 10 mm |

| Black | 40 | 1 mm – 12 mm |

| White | 50 | 2 mm – 14 mm |

| Orange | 60 | 3 mm – 15 mm |

| Blue | 65 | 4 mm – 16 mm |

| Green | 70 | 5 mm – 17 mm |

| Clear | 75 | 6 mm – 18 mm |

| Grey | 80 | 7 mm – 20 mm |

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

- First, confirm your application and basic requirements.

- Measure the installation space and estimate the quantity. If you have drawings, please send them to us. If not, tell us your application, equipment model and working conditions – we can help draft drawings and solutions.

- We will prepare drawings or product proposals based on your requirements and photos.

- Confirm the final size, quantity and key specifications so we can give accurate guidance and a quotation.

- We make samples according to your exact requirements and application.

- You test and confirm the samples; we can upgrade the design if needed.

- Place the formal order and we arrange production.

- We perform outgoing inspection and arrange shipment.

- Our after-sales team follows the goods and provides support continuously.

- Before purchase: we give professional advice to help you choose the right products and system.

- After purchase: warranty is typically 1–2 years depending on the application and your requirements. Damage caused by normal use within the warranty period can be repaired or replaced.

- Long term: we keep providing technical support, monitoring product performance and helping you develop your own brand and market.

Yes. We can provide existing standard samples for free. For custom designs there may be a small sample charge, and new customers are expected to pay the delivery cost. Sample charges can be deducted from the payment of your formal order.

We have a professional QC team and follow Incoming Quality Control, In-Process Quality Control and Outgoing Quality Control throughout our factory. With the right raw materials and strict process control, our silicone products keep stable color, dimensions and mechanical properties over a long service life, helping you reduce downtime and replacement costs.