High Temperature Silicone Sponge Sheet

Thermal insulation Silicone Foam Sheet

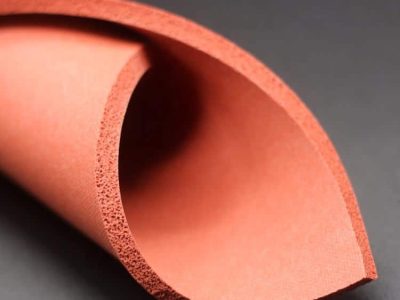

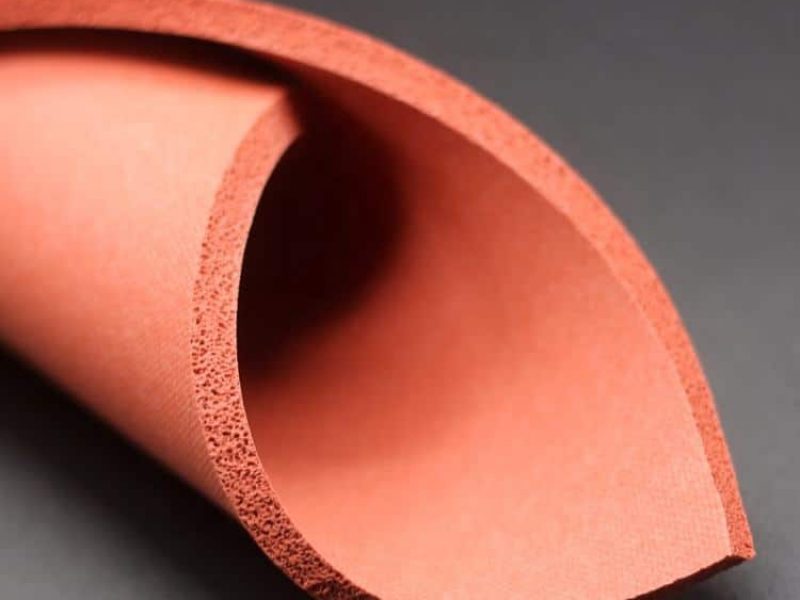

High temperature silicone foam sheets, also called silicone sponge sheets, are designed for applications where thermal insulation, compression cushioning, and environmental sealing are required at elevated temperatures.

Unlike solid silicone sheets, silicone foam offers a cellular structure, lower density, and controlled compression force, making it suitable for enclosure gaskets, thermal barriers, vibration damping, and lightweight sealing in demanding environments.

High Temperature Silicone Foam

Silicone foam is a cellular silicone material produced by expanding a silicone compound during curing. The resulting structure can be:

- Inherent heat resistance of silicone polymer

- Controlled density and compressibility

- Low weight and good resilience

This makes it a preferred choice for thermal management and environmental sealing in enclosures, cabinets, transportation, electronics, and energy systems.

Product Details

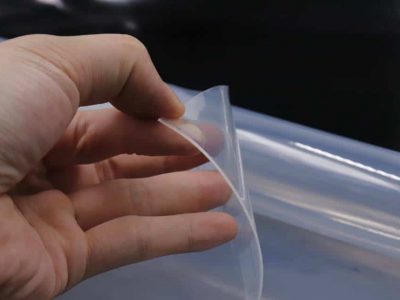

Silicone Rubber Foam Sheet Rolls Supplier

Key Features

The foam structure contains numerous microscopic cells that trap air or gas, which provides:

- Thermal insulation – reduced heat transfer through the gasket or pad

- Compression cushioning – absorbs tolerances and dimensional variation

- Weight reduction – lighter than solid silicone for the same volume

- Continuous temperature: 180–200°C

- Short-term peaks: up to 250–260°C (482–500°F), depending on grade

- Low temperature flexibility: down to −40°C or −60°C, depending on density

The material maintains resilience and compression recovery after repeated thermal cycles.

Silicone Rubber Sponge Sheet Manufacturer

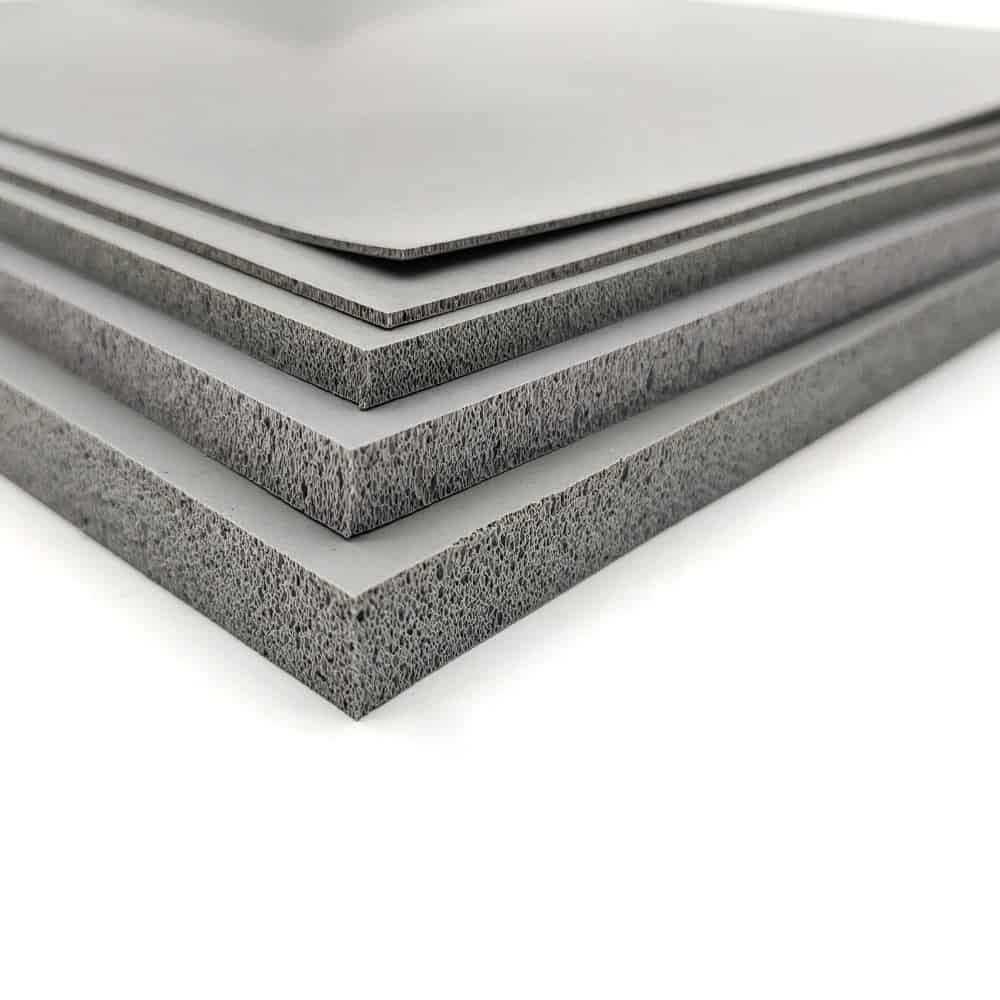

Silicone Foam Sheets Technical Specifications

| Property | Typical Range |

|---|---|

| Material | High temperature silicone foam / sponge sheet |

| Structure | Closed-cell or semi-closed-cell |

| Continuous Temperature | 180–200°C |

| Peak Temperature | Up to 250–260°C |

| Density | Grade-dependent (soft / medium / firm) |

| Compression Force Deflection (CFD) | Designed for enclosure sealing, varies by grade |

| Compression Set | Low, suitable for long-term sealing |

| Thermal Insulation | Good due to cellular structure |

| UV & Ozone Resistance | Excellent |

| Electrical Insulation | Non-conductive |

| Color Options | Grey, white, red, black, custom |

Industry Applications of Silicone Sponge Sheets

Enclosure and Cabinet Sealing

- Electrical and electronic cabinets

- Control panels and junction boxes

- Outdoor enclosures exposed to UV, ozone, and weather

- Telecom and communication equipment housings

- The foam absorbs tolerances and provides environmental sealing at door and panel interfaces.

Thermal Insulation and Heat Shields

- Oven and furnace door seals

- Heat shield interfaces in machinery

- Insulation pads between hot surfaces and panels

- Thermal isolation layers in equipment

- The cellular structure reduces heat conduction and provides a thermal barrier.

Energy, Battery and EV Components

- Battery module perimeter gaskets

- Compression pads in energy storage systems

- Gap fillers for thermal and environmental protection

- Silicone foam combines temperature capability, electrical insulation and compression performance needed in modern energy systems.

HVAC and Appliance Sealing

- HVAC system door gaskets

- Duct joints and access panel seals

- Industrial appliance door and panel gaskets

- Silicone foam maintains sealing performance across wide temperature and humidity ranges.

Transportation and Aerospace

- Rail and rolling stock door gaskets

- Aerospace insulation pads and panel interfaces

- Vehicle interior and under-hood thermal interfaces

- The combination of low weight, temperature resistance and resilience is valuable in these sectors.

Customize Your Silicone Sponge Sheet

---Available Formats and Fabrication Options

High temperature silicone foam sheets can be delivered as:

- Full sheets and rolls

- Strips and tapes

- Kiss-cut parts on liner

- Custom gaskets and frames

- Die-cut, CNC-cut, or water-jet cut parts

---Value-added options

- PSA adhesive backing on one or both sides

- Slit-to-width rolls for continuous gasketing

- Kiss-cut gaskets on release liner for assembly efficiency

---Dimension Capabilities

- Thickness: from thin foam for light sealing up to thicker pads for thermal and cushioning needs

- Width: suitable for enclosure doors, panels and large cabinet frames

- Length / Roll Size: configured according to thickness and handling preferences

Silicone Foam vs Solid Silicone

| Feature | High Temp Silicone Foam | High Temp Solid Silicone |

|---|---|---|

| Structure | Cellular, low density | Solid elastomer, higher density |

| Primary Function | Insulation, cushioning, enclosure sealing | Load-bearing sealing and gasketing |

| Compression Force | Lower, controlled CFD | Higher, rigid sealing |

| Weight | Lightweight | Heavier |

| Thermal Insulation | Good due to cellular structure | Lower insulation performance |

| Fluid Sealing | Good (closed-cell grades) | Excellent |

| Typical Use Cases | Cabinets, HVAC, batteries, electronics | Flanges, press pads, industrial gaskets |

In short:

Use silicone foam sheet when the main needs are insulation, gap filling, enclosure sealing, flame resistance, and cushioning.

Use solid silicone sheet when the main needs are tight fluid sealing and load-bearing gaskets.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

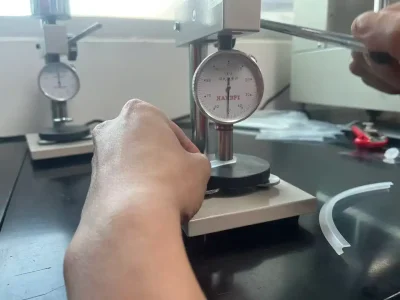

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Compared to other common foams:

Silicone foam VS EPDM foam:

Silicone foam offers higher temperature capability and better UV/ozone resistance. EPDM foam is more limited in temperature but may be cost-effective for moderate conditions.

Silicone foam VS polyurethane foam:

Silicone foam provides much better high temperature and weather resistance. Polyurethane foams often degrade more quickly under heat and UV exposure.

Silicone foam VS solid silicone:

Foam provides better thermal insulation and is more suitable for enclosure and cabinet sealing; solid silicone provides tighter fluid sealing and higher load-bearing capacity.

To specify a silicone foam sheet or gasket, typical information includes:

Target operating temperature

Desired flame rating or regulatory tests

Thickness and density grade

Gasket shape, width and frame dimensions

Need for adhesive backing or liner

With this information, the appropriate foam grade and fabrication method can be recommended to meet both performance and cost targets.

Silicone foam has a cellular, lower density structure designed for insulation, gap filling and enclosure sealing, while solid silicone sheet is a dense elastomer designed for load-bearing gasket sealing. Foam is selected for panel interfaces and cabinets; solid is selected for flange sealing and press pads.

Yes. The cellular structure traps air within the material, reducing heat transfer and providing thermal isolation while maintaining compression behavior.