Drill Rig Safety Floor Matting

In the high-stakes environment of a drilling rig, a split-second slip can lead to catastrophic injuries or costly operational downtime. Our Drill Floor Safety Matting is specifically engineered to eliminate these risks. Manufactured from premium, high-density Polyurethane (PU), these mats provide an aggressive anti-slip surface that remains effective even when saturated with heavy drilling mud, crude oil, or ice.

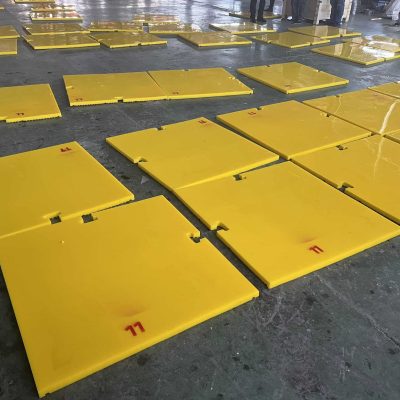

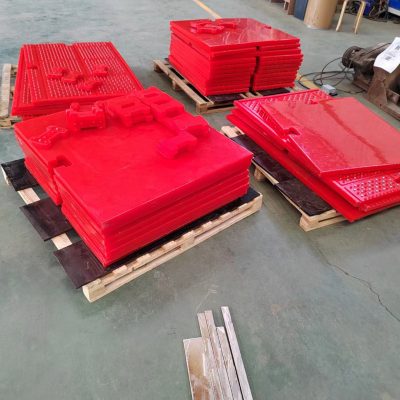

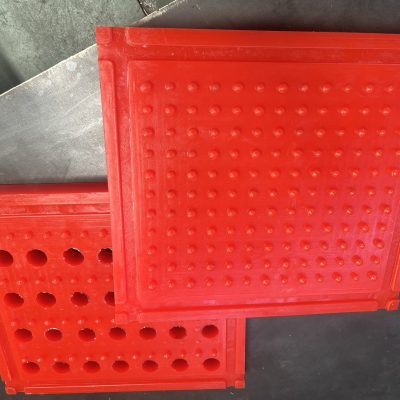

Various of Custom Drilling Rotary Table Mats

Drilling Floor Safety Mats Manufacturer

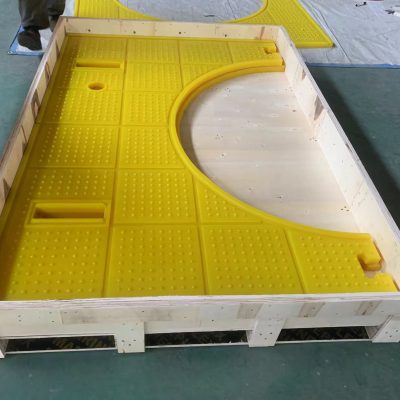

Rotary Table Safety Mats

Key Features:

- High traction surface – Prevent slips and falls

- High wear resistant

- Discharge water & oil in time

- Improves workplace safety

- The mat can custom fit to size

- Easily installed – reducing labour intensive installation time and costs.

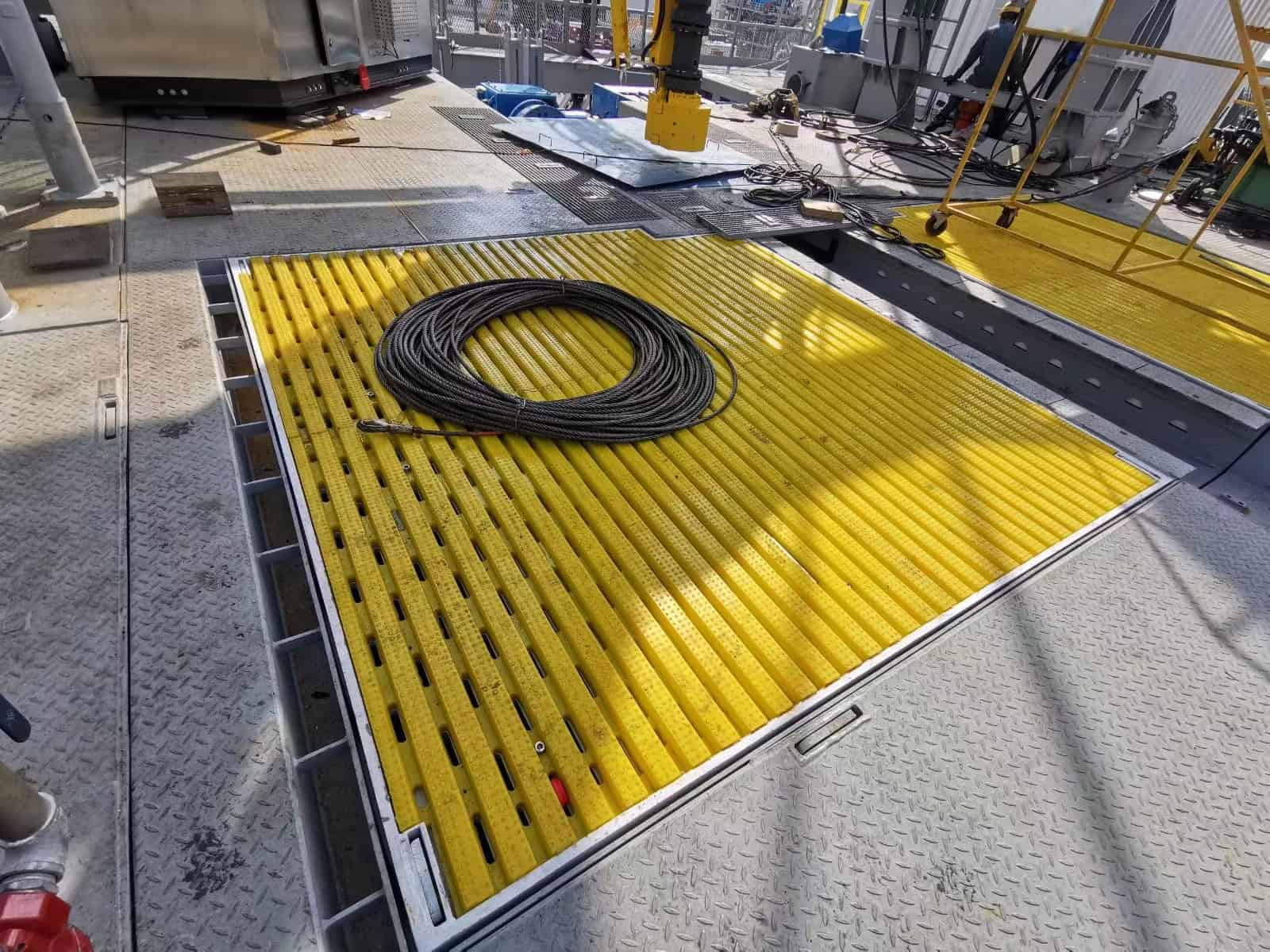

Heavy duty Safety Floor Matting

Technical Parameters:

- Size: SU-ZP-175, SU-ZP-205, SU-ZP-275, SU-ZP-375, Customize as drawings

- Color: Yellow, plays the role of safety warning

- Material: High wear resistance, oil resistance, Polyurethane Rubber+Carbon/Stainless Steel

- Break Strength: 50 MPA

- Elongation at Break: 550%

- Hardness: 93 +/- 3 Shore A

- Tearing Strength: 105.0 KN/m

- Rebounding: 20%

Setback Area Pipe Racking Mats

Applications:

- Rotary Tables

- Drill Floors/Decking Areas

- Monkey Boards

- Pump Room/Mud Pits

- Stairs & Walkways

- Setback Area

Rotary table polyurethane mat

| Order No. | Length | Width | Diameter of Center Bore | Thickness |

|---|---|---|---|---|

| SU-ZP-175 | 1690 | 1280 | 780 | 30 |

| SU-ZP-205 | 2000 | 1490 | 830 | 30 |

| SU-ZP-275 | 2100 | 1670 | 1050 | 30 |

| SU-ZP-375 | 2205 | 1810 | 1290 | 30 |

* All dimensions are in millimeters (mm). Custom sizes and bore diameters are available upon request.

Polyurethane mat vs. Rubber vs. Wood

| Feature | Our High-Grade PU | Standard Rubber | Wood / Timber |

|---|---|---|---|

| Oil & Mud Grip | Excellent (Anti-Slip) | Poor (Slippery when wet) | Very Poor (Absorbs oil) |

| Chemical Stability | Immune to Hydrocarbons | Swells & Softens | Rots & Decays |

| Impact Resistance | Extreme (Absorbs Force) | Moderate | Splinters / Cracks |

| HSE Compliance | Fire & Anti-Static Rated | Limited | Fire Hazard |

| Service Life | 5+ Years | 1 Year | < 6 Months |

| Total ROI | Highest (Low Maintenance) | Medium | Lowest (Frequent Replacement) |

We aware of

Showcase of Drill Floor Mat, Rotary Table Mats

About Company

High-traction Drill Floor Safety Mat Supplier

Suconvey Wholesale Can Be Easy & Safe.

Suconvey is a professional PU rubber products manufacturer that chooses the highest quality raw materials from all over the world as our long time experience in this industry after comparing the materials from different countries and districts, we get rid of the materials with any bad feedback and products.

- Shenzhen Suconvey Rubber Products Co., Ltd.

- 86-13246961981

- [email protected]

- Ronglichang Industrial Park, No. 4 Zijing Road, Longgang District, Shenzhen City

Free Consultation

Get a free quote

Why global customers trust Suconvey

China Drilling Floor Safety Matting Manufacturer

Professional Service

We have a professional service team that provides 24-hour service. From your drilling floor safety mats order, design, production to after-sales, there are professionals to provide you with advice and solutions.

Guaranteed Quality

We have professional testing equipment to perform performance tests on drill floor mats according to your needs. During the production process of safety mat, multiple rounds of testing and inspection will be carried out to ensure 100% factory testing to ensure the quality.

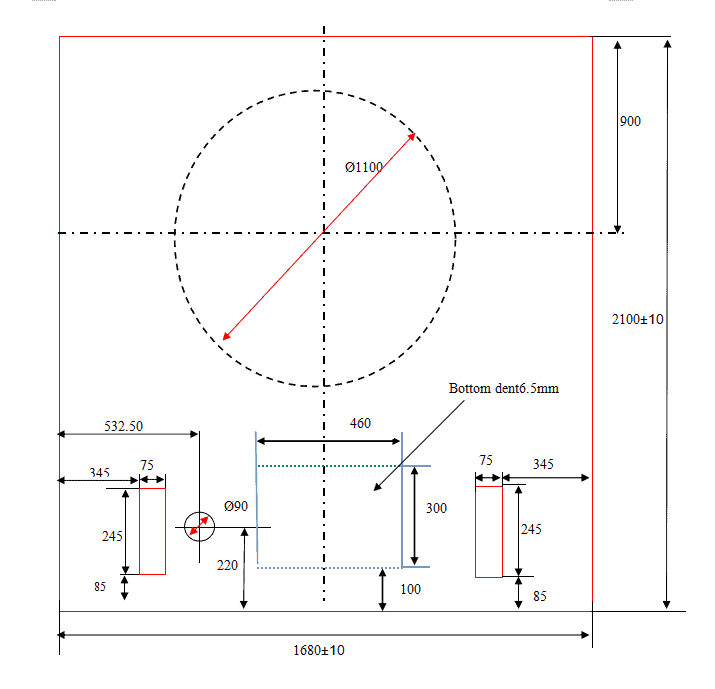

Provide OEM and ODM Services for You

For rig mats, you can send us your 2D drawings or 3D CAD models, and we can customize them according to your size, description, drawings, samples, etc. We can also print your logo brand on the mat and provide customized packaging, etc.

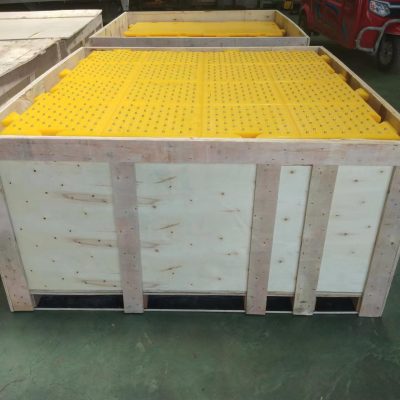

Short Delivery Time

Whether you are placing a large order or a minimum order, we have advanced production equipment and a skilled production team, and have the strong ability to handle your rig floor mat order. We have been working with professional freight forwarders for many years and have the ability to clear customs, ensuring that you can receive the goods safely and on time.

Efficiently and Tidy

Drilling Rotary Table Safety Mat Process

- Determine the impact and damage force suffered by the polyurethane mats.

- According to the analysis result, specify the polyurethane formula.

- According to the formulated formula to process the polyurethane raw material.

- Treat and clean the mold.

- Inject the formulated polyurethane material into the mold through a glue injecting machine, and produce a sample. Test the sample and check whether the coefficients are up to standard.

- If metal parts are necessary, put the treated and clean metal parts into the mold and begin to inject with polyurethane.

- After the polyurethane vulcanization is completed, inspect the appearance of the product and do the following treatments.

- Packaging of finished drilling floor mats for shipment.

Most frequent questions and answers

FAQs

Yes. We specialize in custom-engineered solutions. We can manufacture mats with precision cut-outs for the rotary table, setback areas, mouseholes, and monkey board. Simply provide us with your rig floor drawings (STP, CAD, or PDF), and we will create a seamless fit.

Our mats feature a multi-directional drainage channel system. This allows drilling mud, oil, and water to flow beneath the standing surface, ensuring that the worker’s boots always maintain contact with the anti-slip studs rather than floating on a film of liquid.

In a typical 24/7 drilling environment, our Polyurethane matting lasts 4 to 6 times longer than traditional rubber or wood. While wood rots and rubber swells when exposed to oil, our PU remains structurally sound, providing a much lower “Total Cost of Ownership” over the life of the rig.

No. We use a specialized low-temperature PU formulation that remains flexible and retains its “grip” at temperatures as low as -40°C. Unlike rigid plastics that become brittle and slippery in the cold, our mats provide consistent traction year-round.

Yes, we offer a specific Anti-Static (Conductive/Dissipative) grade. This is essential for preventing spark discharge on the drill floor, ensuring the matting is safe for use in Zone 0, 1, or 2 hazardous areas.

Polyurethane (PU) is significantly more resistant to oil and chemicals, which cause rubber to soften and degrade. PU also offers much higher tear strength and abrasion resistance, making it the superior choice for the heavy impact found on a drill floor.

Our drilling floor mat is made of highly abrasion-resistant and impact-resistant polyurethane. Its benifits: reduce slips, trips and falls, enhanced level of safety, economic applications, long lasting, improved asset integrity

1. There are square areas enclosed by many vertical and horizontal drainage grooves the drainage groove on the main mat, protruding rubber particles, and metal nails embedded on the protruding surface square area.

2. The rubber particles and metal nails that are regularly staggered can not only effectively prevent slipping, but also make the operator stand on the pad without discomfort.

3. Liquid can be discharged from the space of nails and particles and then flow into the drainage grooves, last removed to the specific place without flow into river or sea. So the construction site is clean and firm.

Since the surface of the anti-skid pad has vertical and horizontal drainage grooves, oil or water can flow into the grooves and be discharged in time, reducing the influence of oil or water on the anti-skid effect.

Yes. Our matting system is designed for easy retrofitting.