Fluorosilicone Sheet

Fluorosilicone Sheet Supplier

Fluorosilicone sheet (FVMQ) is designed for demanding sealing applications where standard silicone fails in contact with fuels, oils and aggressive chemicals. It combines the wide temperature range and flexibility of silicone with the fuel, oil and solvent resistance of fluorocarbon elastomers.

Suconvey supplies fluorosilicone rubber sheets and rolls for aerospace, automotive, chemical processing and other industries that require long-term sealing performance in harsh fluid environments.

Fluorosilicone Rubber Sheet

Fluorosilicone rubber is a fluorinated silicone elastomer (FVMQ). By introducing fluorine into the silicone polymer, the material:

- greatly improves resistance to hydrocarbon fuels, mineral oils, synthetic lubricants and many solvents

- maintains typical silicone advantages such as wide service temperature range and excellent weathering resistance

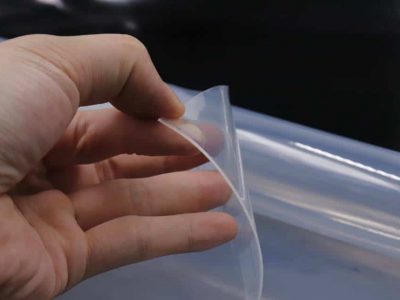

Fluorosilicone rubber sheet is produced as cured, ready-to-use sheet material that can be die-cut or CNC-cut into gaskets, strips and pads.

Compared with standard silicone sheet, fluorosilicone is chosen when:

- the gasket is continuously exposed to fuel, oil, ATF, hydraulic fluid or aggressive chemicals

- the seal must survive cold starts and high operating temperatures

- there is a requirement for long service life and low compression set in critical systems

Product Details

Fluorosilicone Sheet Supplier

Key Features

- Outstanding fuel & oil resistance – suitable for contact with aviation fuel, diesel, gasoline, mineral and synthetic oils, and many solvents.

- Wide operating temperature range – typical use from −60°C up to +200°C, with some grades suitable for intermittent higher temperatures.

- Excellent low-temperature flexibility – remains elastic at very low temperatures, important for cold-start conditions in fuel and oil systems.

- Good compression set resistance – maintains sealing force after long-term compression in static gasket applications.

- Resistance to weathering, ozone and UV – suitable for outdoor and aerospace environments.

- Good electrical insulation properties – usable in electrical and electronic sealing where fluids are present.

- Available in solid sheet and custom cut gaskets – supports OEM projects and maintenance replacements.

China Fluorosilicone Sheet Manufacturer

Technical Specifications

| Fluorosilicone Rubber Sheet – Typical Properties | |

|---|---|

| Polymer Type | Fluorosilicone rubber (FVMQ) |

| Specific Gravity | Approx. 1.45–1.55 g/cm³ |

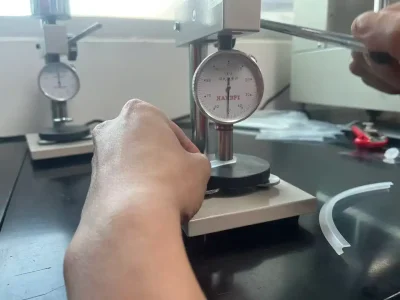

| Hardness | 40–70 Shore A (standard 60 Shore A) |

| Tensile Strength | 6–8 MPa (approx. 870–1,150 psi) |

| Elongation at Break | 150–300% |

| Temperature Range | −60°C to +200°C (grade dependent) |

| Fuel & Oil Resistance | Excellent – suitable for many fuels, oils and solvents |

| Weathering & Ozone Resistance | Excellent |

| Typical Forms | Rolls, sheets, die-cut and CNC-cut gaskets |

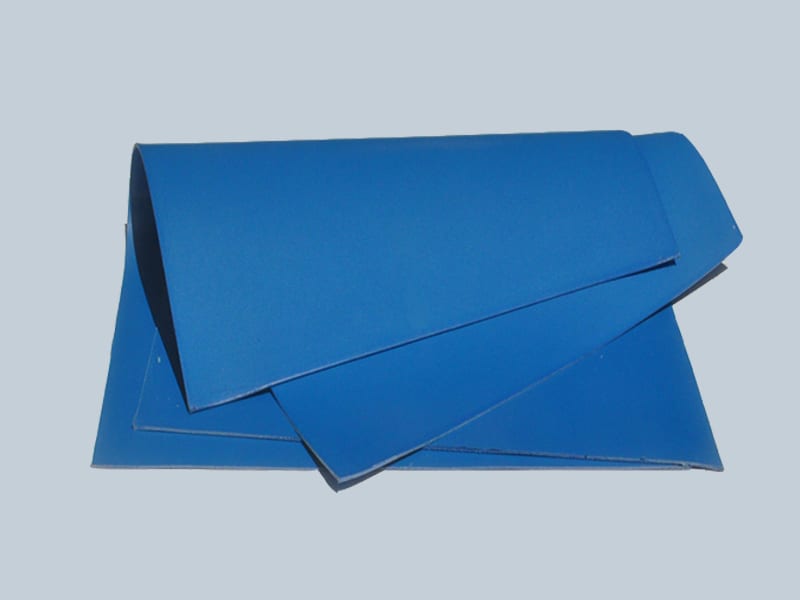

| Standard Color | Blue (other colors on request) |

Industry Applications of Fluorosilicone Sheets

Aerospace & Aviation

- Gaskets and seals in aircraft fuel systems

- Static seals for hydraulic and lubrication systems

- Environmental sealing in aviation electronics exposed to jet fuel fumes

Automotive & Transportation

- Fuel system gaskets and covers

- Seals exposed to gasoline, diesel and transmission fluids

- Under-hood components exposed to oil mists and temperature cycling

Chemical & Industrial Processing

- Seals for equipment handling aggressive fluids and solvents

- Gaskets in process lines where standard silicone swells or degrades

- Static sealing in pumps, valves and flanges with mixed media exposure

Electronics & Specialty Equipment

- Seals and pads in equipment exposed to fuel vapor, oils or coolants

- High-reliability static gaskets for instrumentation in harsh environments

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Choose fluorosilicone when your application involves continuous or repeated contact with fuels, oils, transmission fluids or aggressive solvents, and you still need a wide service temperature range and good low-temperature flexibility.

Yes. Fluorosilicone is widely used for O-rings and gaskets in fuel and oil systems. For high-speed dynamic applications, we can help you evaluate the compound and surface finish.

Typical working range is around −60°C to +200°C, depending on the grade and environment. Short-term peaks above this range may be possible for certain formulations – please share your process details for confirmation.

Yes. We can provide small sample pieces or trial gaskets so you can evaluate swelling, compression set and sealing behavior in your actual fluids and temperature conditions before ordering production quantities.