Backed Adhesive Silicone Sheet

Silicone Rubber Sheets with adhesive Supplier

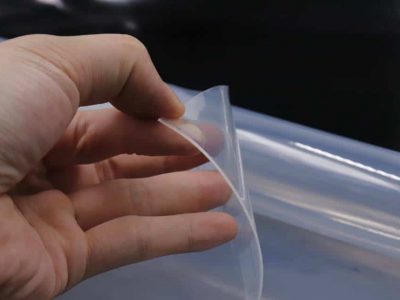

Backed adhesive silicone sheet (peel-and-stick silicone rubber sheet) combines the high temperature, weather and electrical insulation performance of silicone with the convenience of a factory-applied pressure sensitive adhesive (PSA) backing.

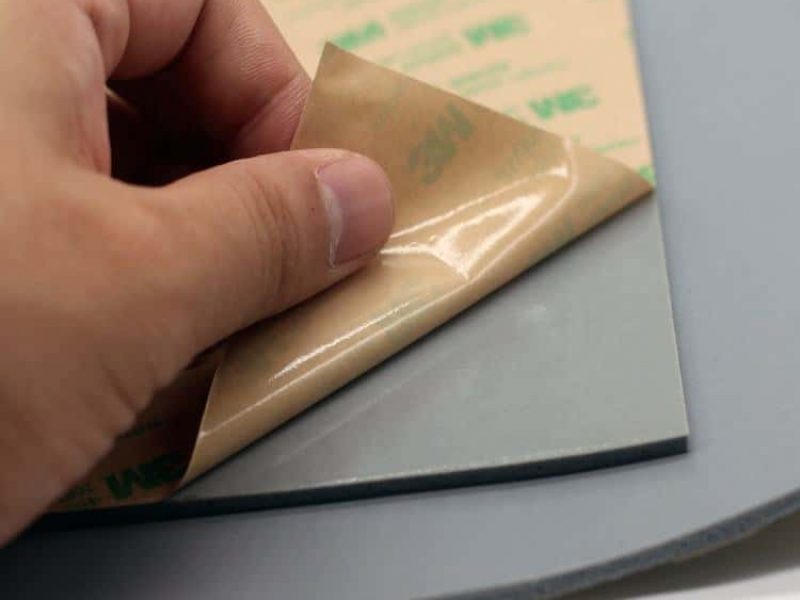

You simply peel off the release liner and bond the sheet directly to metal, glass, plastic or painted surfaces without separate glue, saving time and avoiding mess on the production line.

Suconvey supplies custom adhesive backed silicone sheet rolls and cut parts for industrial OEMs, equipment builders and maintenance users who need reliable, long-lasting bonding under demanding conditions.

Backed Adhesive Silicone Rubber Sheet

Backed adhesive silicone sheet is a silicone rubber sheet with an adhesive layer pre-laminated to one side, protected by a removable release film or paper.

The silicone side provides high temperature resistance, flexibility, sealing and electrical insulation.

The adhesive side uses industrial PSA – typically acrylic or silicone adhesive – to create a strong, consistent bond on the mounting surface.

Compared with using loose silicone sheet plus separate glue, a backed adhesive sheet:

- reduces assembly steps and labor cost

- improves thickness and positioning consistency

- avoids contamination from over-applied liquid adhesive

- enables clean removal and replacement in many applications

Product Details

Silicone Rubber Sheet with adhesive Supplier

Key Features

- Peel-and-stick installation – no separate adhesive required, fast to mount on metal panels, housings, doors and frames.

- High temperature performance – suitable for many applications from −50°C to +230°C, depending on compound and adhesive system.

- Strong, reliable bond – engineered PSA for metals, plastics and painted surfaces, with good resistance to vibration and thermal cycling.

- Excellent electrical insulation – silicone rubber provides stable dielectric strength and tracking resistance.

- Weather, ozone & UV resistant – ideal for outdoor equipment, LED lighting housings, control boxes and enclosures.

- Clean, uniform appearance – neat edges and controlled thickness for professional OEM finish.

China Back Adhesive Silicone Sheet Manufacturer

Technical Specifications

| Base Material | Silicone rubber (VMQ), solid or foam sheet |

| Adhesive Type | Acrylic PSA or 3M Adhesive |

| Service Temperature (Acrylic PSA) | Typically up to +120°C continuous |

| Thickness Range (Silicone) | 0.2–10.0 mm (custom on request) |

| Standard Width | Up to 3,000mm depending on grade |

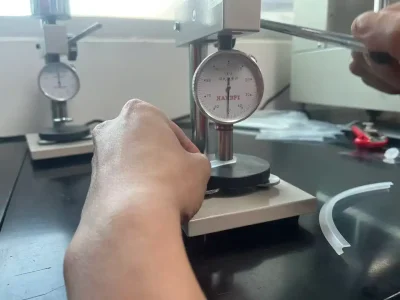

| Hardness | 20–80 Shore A |

| Color | Red, grey, black, white or custom |

| Surface Finish | Smooth or matte |

| Dielectric Strength | Good electrical insulation (exact value by grade) |

| Available Forms | Rolls, sheets, die-cut or CNC-cut parts with liner |

Best Choice for Your Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---Processing & Custom Services

Suconvey not only supplies bulk rolls – we also deliver ready-to-use components:

- Precision slitting for strips and tapes

- CNC and die-cut gaskets on release liner

- Kiss-cut parts for fast peel-off during assembly

- Laminating different PSA systems according to your substrate

- Printing or marking part numbers on the liner (on request)

---OEM & Branding Service

We support OEM cooperation for equipment manufacturers and distributors. Products can be supplied under your brand, part code, or specification. Lot numbers and QC labels can be printed for traceability if required.

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

Industry Applications

Gasketing & Sealing

- Peel-and-stick door and panel gaskets

- Enclosure seals for electrical cabinets and control boxes

- Access panel gaskets in HVAC and industrial machinery

Thermal & Electrical Insulation

- Insulation pads bonded inside ovens, dryers and heaters

- Electrical insulation layers on busbars, power supplies and PCB enclosures

- Anti-tracking barriers and protective lining for high-voltage equipment

Vibration Damping & Cushioning

- Anti-vibration pads under pumps, compressors and fans

- Protective lining strips on machine guards and metal edges

- Anti-slip, shock-absorbing surfaces on equipment contact points

General Industrial Bonding

- Lining for chutes and slides where a soft, non-stick surface is needed

- Bonded silicone pads for clamping fixtures and test equipment

- Temporary or semi-permanent protection pads in assembly operation

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

It simplifies installation. You get the performance of silicone rubber with a factory-applied adhesive, so you can peel and stick the sheet directly onto your parts without handling liquid glue or extra tapes.

Yes, but the exact temperature limit depends on the adhesive system. Standard acrylic PSA works well for many applications up to around 120°C, while silicone PSA is more suitable for continuous high temperature or thermal cycling. Tell us your operating temperature and we will match the right PSA.

Yes. We can supply finished gaskets, strips and pads cut from adhesive backed silicone sheet using CNC, die-cutting or kiss-cutting, delivered on a liner for easy handling.

We can send sample sheets or strips so you can test adhesion, temperature resistance and assembly performance on your equipment before placing a bulk order.