Super Clear Silicone Sheet Roll

Transparent Silicone Rubber Sheets Supplier

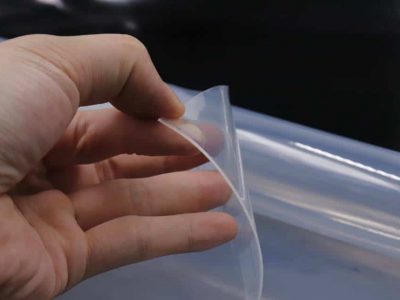

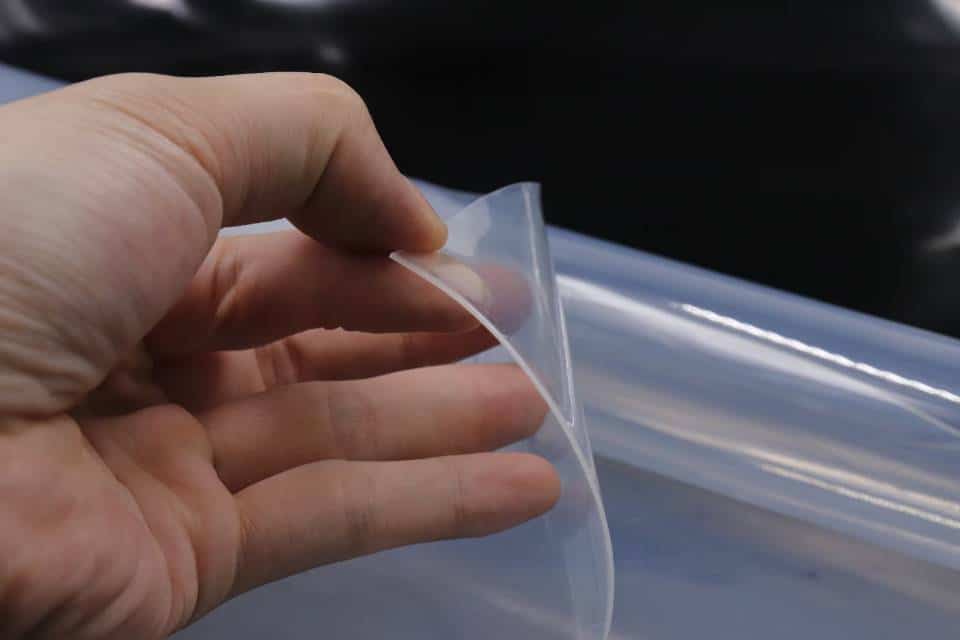

Super clear silicone sheets are optical-grade elastomers designed for applications requiring both mechanical sealing and visual transparency.

Unlike standard silicone sheets, which appear opaque or translucent, super clear silicone provides a highly transparent, non-yellowing surface that maintains clarity over time under indoor or outdoor exposure.

This makes it suitable for lighting gaskets, viewing windows, display covers, instrument panels, laboratory equipment, inspection ports and visually monitored sealing interfaces.

Why Select Super Clear Silicone Instead of Standard Silicone Sheets

Standard silicone sheets deliver thermal and mechanical performance, but may:

- appear milky or opaque

- scatter light

- yellow over time

- obstruct visibility

- compromise lighting aesthetics

Super clear silicone addresses these limitations with improved optical clarity, making it suitable for aesthetic, inspection or imaging-related systems.

Product Details

Transparent Silicone Sheet Rolls Supplier

Key Features

Super clear silicone sheets are formulated using platinum-cured PDMS (polydimethylsiloxane) elastomers with enhanced optical clarity. The material offers:

- High transparency

- Non-yellowing performance

- Low extractables

- Excellent UV and weather resistance

- Temperature stability

- Clean appearance for exposed sealing interfaces

It preserves the core benefits of silicone rubber while enabling visual inspection through the gasket, sheet or cover layer.

China Super Clear Silicone Rubber Sheet Manufacturer

Clear Silicone Sheet Technical Specifications

| Category | Performance |

|---|---|

| Temperature Range | −60℃ to +230℃ |

| Compression Set | Low |

| UV / Ozone Resistance | Excellent |

| Weathering | Excellent |

| Chemical Resistance | Resistant to mild media |

| Electrical Properties | Insulating |

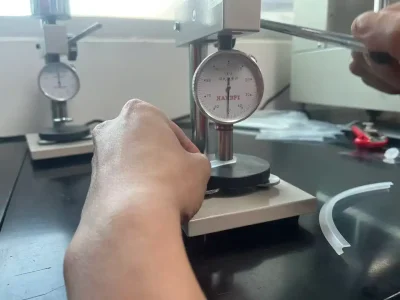

| Hardness | 20–80 Shore A (grade dependent) |

Wholesale Silicone Sheet Rolls

Ordering & Specification Information

To specify super clear silicone sheets, OEMs typically define:

- Thickness

- Hardness

- Transparency level

- Surface finish

- Dimensional format (roll / sheet / gasket)

- Application environment

- Regulatory requirements (optional)

- Adhesive requirement (optional)

- Quantity & packaging preferences

Super Clear vs Other Silicone Sheet Types

| Type | Transparency | Temperature Capability | Regulatory Focus | Typical Use |

|---|---|---|---|---|

| Super Clear Silicone Sheet | High | High | Optional food/medical grades | Lighting, displays, viewing windows, transparent covers |

| Food Grade Silicone Sheet | Medium | High | FDA and food contact compliance | Food processing equipment, conveyors, baking mats |

| Platinum-Cured Silicone Sheet | Medium–High | High | Purity, low extractables, medical and pharma use | Medical devices, pharmaceutical seals, sanitary lines |

| High Temperature Solid Silicone Sheet | Opaque | Very high | Industrial and thermal sealing | Flange gaskets, heat press pads, industrial sealing |

| Silicone Foam Sheet | Opaque | High | Optional flame rating and enclosure sealing | Cabinet gaskets, HVAC, insulation and cushioning |

Industry Applications of Clear Silicone Sheets

Lighting & Illumination Systems

- LED lighting gaskets

- Diffuser and lens seals

- Outdoor lighting panels

- Architectural lighting fixtures

Display & Electronics Interfaces

- Display windows

- Touch interfaces

- Protective covers for instruments

- Device seals with visible interiors

Laboratory & Scientific Equipment

- Transparent cover sheets

- Cell culture plate seals

- Lab inspection windows

- Moisture & vapor barrier functions

Industrial & Manufacturing Systems

- Observation ports

- Inspection chambers

- Machinery viewing gaskets

- Transparent process covers

Medical, Dental & Optical Components

- Medical visualization windows

- Dental equipment covers

- Small optical sealing pads

- Device housings requiring clarity

Best Choice for Your Clear Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for platinum-cured silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---Industries Served

- Lighting & illumination manufacturers

- Display & electronics integrators

- Scientific laboratory equipment OEMs

- Medical & dental device OEMs

- Instrumentation & metrology systems

- Industrial machinery

- Consumer electronics

- Architectural lighting & signage

---OEM & Branding Service

- Prototyping

- Die-cutting & CNC fabrication

- Private label production

- Long-term supply agreements

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

---Quality Assurance

Each batch undergoes hardness, thickness, and visual checks with recorded batch data for traceability. Compliance with food-contact regulations is verified through third-party laboratory testing when required by the customer.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Super clear silicone sheet offers much higher optical clarity and non-yellowing performance. Standard silicone sheets are opaque or milky, while super clear silicone allows light transmission and visual inspection through the sheet or gasket.

Yes. Super clear silicone sheet is platinum cured to reduce extractables, prevent discoloration and maintain clarity over time. Platinum curing also produces lower odor and cleaner surfaces compared with peroxide-cured silicone.

No. Super clear silicone sheets retain the flexibility, tensile strength and elasticity of high-quality silicone rubber, allowing them to be used for functional gaskets as well as visual covers.

Yes. Pressure-sensitive adhesive (PSA) can be applied for bonding to housing frames, lighting enclosures, panels or covers, allowing fast OEM assembly or field installation.

Super clear silicone sheet can be supplied in a wide thickness range suitable for both optical covers and mechanical sealing. Thin films are suitable for display and protective layers, while thicker sheets provide cushioning and sealing.