Ultra Thin Silicone Membrane

Ultra Thin Silicone Film Supplier

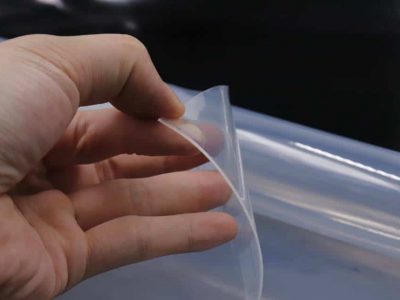

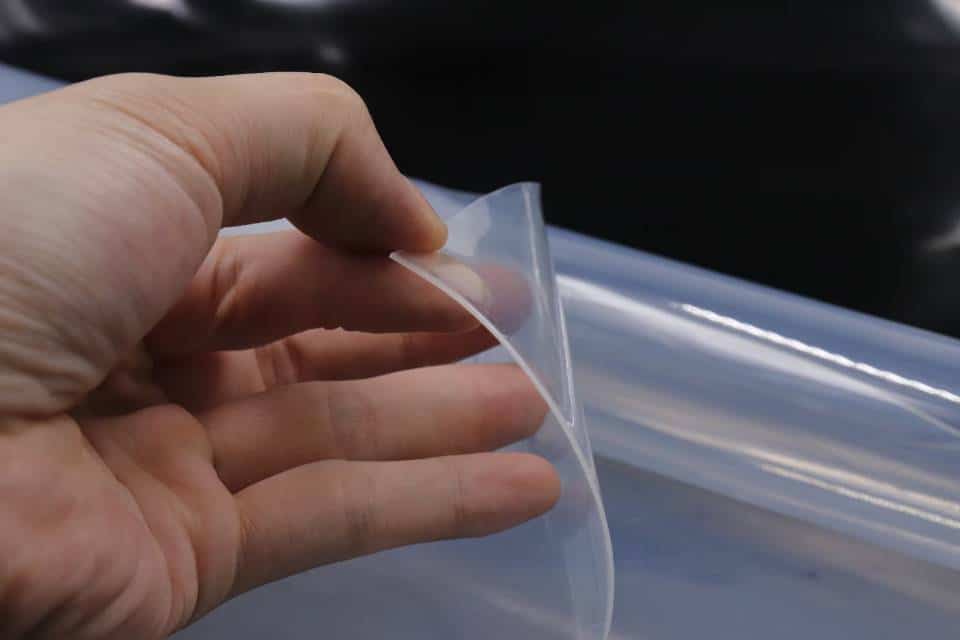

Ultra thin silicone membranes are precision-engineered silicone films designed for applications where a very small thickness, high flexibility, and stable mechanical response are critical.

Compared with standard silicone sheets, ultra thin membranes are supplied in film form with tightly controlled thickness, excellent elastic recovery, high dielectric strength and good permeability to gas and water vapor.

They are widely used in diaphragms, sensors, laboratory devices, vacuum laminating processes, optical covers, medical components and any situation where a thin, clean, flexible barrier is required instead of a conventional rubber sheet.

Ultra Thin Silicone Membrane

Ultra thin silicone membrane is a calendered or cast silicone elastomer produced in very small thicknesses, typically well below standard sheet ranges. It maintains the core advantages of silicone rubber:

- Wide operating temperature range

- Good elastic behavior and low compression set

- Resistance to UV, ozone and weathering

- Chemical inertness to many common media

- but in a film-like form factor that can bend, stretch and flex with minimal resistance.

In addition, ultra thin silicone membranes are:

- Highly flexible even at low temperatures

- Dimensionally stable under repeated mechanical cycling

- Permeable to gas and water vapor

- Dielectrically strong for electrical insulation and sensor protection

These combined properties make them suitable for precision diaphragms and functional films where traditional rubber sheets are too thick or too stiff.

Product Details

Ultra Thin Silicone Sheet Rolls Supplier

Key Features

- Very small thickness compared with standard sheets

- Uniformity across the sheet or roll

- Minimal thickness variation for consistent mechanical behavior

- Resistant to weathering, UV radiation and ozone

- Suitable for both indoor and outdoor environments

- Low modulus and soft feel

- Low hysteresis in diaphragm and sensor applications

- Good tear resistance relative to thickness

China Silicone Membrane Sheet Manufacturer

Ultra Thin Silicone Membrane Technical Specifications

| Property | Typical Range / Description |

|---|---|

| Form | Ultra thin silicone membrane / film |

| Thickness | Very small thickness with tight tolerance (film grade) |

| Temperature Range | −60℃ to +200℃ (application dependent) |

| Flexibility | Very high, low bending stiffness |

| Elastic Behavior | Good elastic recovery and low compression set |

| UV / Ozone Resistance | Excellent |

| Weathering Resistance | Excellent |

| Gas & Vapor Permeability | High relative permeability (per unit thickness) |

| Electrical Properties | Good electrical insulation, high dielectric strength |

| Typical Applications | Diaphragms, sensors, lab devices, vacuum laminating, thin seals |

Industry Applications of Ultra Thin Silicone Sheets

Diaphragms & Pressure Sensors

- Pneumatic and hydraulic diaphragms

- Low-pressure and differential pressure sensors

- Pump and valve diaphragms

- Instrument and gauge isolation membranes

Laboratory & Medical Devices

- Microfluidic interfaces

- Cell culture and laboratory sealing films

- Bioreactor and analytical equipment membranes

- Flexible covers and viewing windows

Vacuum Laminating & Composite Processes

- Vacuum membrane for laminating delicate surfaces

- Protective films for solar panel or display lamination

Electronics, Optics & Protection Films

- Insulating film over circuits and modules

- Flexible dielectric layers

- Protective covers for displays and sensors

- Thin optical covers where some flexibility is required

Sealing Films & Gaskets in Tight Spaces

- Thin sealing film

- Spacer or interface layer

- Low-profile gasket in compact assemblies

Best Choice for Your Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---OEM & Branding Service

We support OEM cooperation for equipment manufacturers and distributors. Products can be supplied under your brand, part code, or specification. Lot numbers and QC labels can be printed for traceability if required.

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

---Quality Assurance

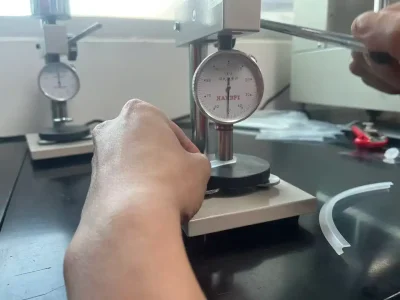

Each batch undergoes hardness, thickness, and visual checks with recorded batch data for traceability. Compliance with food-contact regulations is verified through third-party laboratory testing when required by the customer.

Ultra Thin Silicone Membrane vs Standard Silicone Sheet

| Feature | Ultra Thin Silicone Membrane | Standard Silicone Sheet |

|---|---|---|

| Form | Film / membrane | Sheet / slab |

| Thickness | Very small, tightly controlled thickness | Wider thickness range, bulk material |

| Flexibility | Very high, low bending stiffness | Higher stiffness, more rigid |

| Gas & Vapor Permeability | High relative permeability per unit thickness | Lower permeability per unit thickness |

| Typical Use | Diaphragms, films, lab and sensor interfaces | Gaskets, pads, general sealing applications |

| Dielectric Function | Excellent as thin insulating film | Used as bulk insulator and gasket material |

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Ultra thin silicone membranes are used in diaphragms, pressure sensors, laboratory devices, microfluidic systems, flexible lab covers, vacuum laminating processes and compact sealing applications where a traditional silicone sheet would be too thick or stiff.

Ultra thin silicone membranes are available in a range of film-level thicknesses suitable for diaphragm, lamination, laboratory and sensor applications. Exact thickness options depend on grade and intended function.

Yes. Ultra thin silicone membranes are widely used as flexible vacuum membranes for laminating delicate surfaces, displays, photovoltaic modules and composite layers due to their flexibility and thermal tolerance.

Yes. Ultra thin membranes can be fabricated by die-cutting, CNC cutting, laser cutting or water jet cutting into discs, frames, diaphragms and custom profiles for OEM integration.

Silicone offers chemical inertness to many common lab media and cleaning agents. For biomedical applications, additional testing or compliance may be required depending on direct contact requirements.

Yes. Ultra thin silicone membranes can be supplied as sheets, continuous rolls or converted into diaphragms, frames and custom shapes for OEM builds and prototyping.