Food Grade Silicone Sheet Roll

Premium FDA Silicone Sheets Supplier

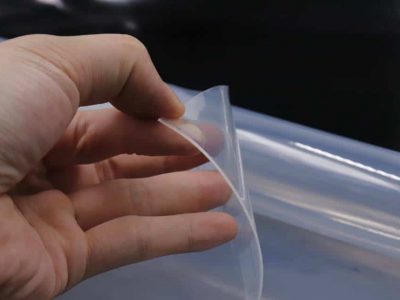

FDA-approved silicone sheeting is designed to ensure non-toxicity, high durability, and thermal stability in environments that require reliable, safe material for food processing, packaging, and industrial applications.

FDA and LFGB Certification>>

Our silicone sheets are FDA-approved for food contact and LFGB compliant.

Temperature Resistance>>

Our silicone sheets perform in a wide temperature range from −60°C to +300°C, ideal for high-heat applications such as food cooking, baking, and industrial processing.

Non-Toxic & Safe>>

Free from harmful substances like phthalates, BPA, and other toxins.

High Durability>>

Silicone sheets offer exceptional abrasion resistance.

Customization>>

Available in a variety of thicknesses, sizes, and hardnesses, with custom cutting and backing options.

FDA Approved Silicone Sheet

Our FDA-grade silicone sheets are perfect for applications where food contact is required. These sheets are compliant with FDA and LFGB standards for safe use in the food industry.

Product Details

FDA Approved & Customizable Silicone Sheet Rolls Supplier

Key Features

- FDA and LFGB Certification: Our silicone sheets are FDA-approved for food contact and LFGB compliant to meet global safety standards.

- Temperature Resistance: Our silicone sheets perform in a wide temperature range from −60°C to +300°C, ideal for high-heat applications such as food cooking, baking, and industrial processing.

- Non-Toxic & Safe: Free from harmful substances like phthalates, BPA, and other toxins, ensuring complete safety for food handling and storage.

- High Durability: Silicone sheets offer exceptional abrasion resistance, maintaining integrity even under repeated use in high-friction applications.

- Customization: Available in a variety of thicknesses, sizes, and hardnesses, with custom cutting and backing options to fit your precise needs.

China Food Safe Silicone Rubber Sheet Manufacturer

Food Grade Silicone Sheet Technical Specifications

| Specification | Details |

|---|---|

| Material | Food-grade silicone rubber |

| Temperature Range | −60°C to +300°C |

| Thickness | 0.2mm – 50mm (custom sizes available) |

| Length | Continuous rolls or custom-cut sheets |

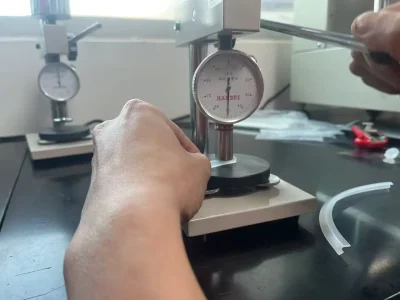

| Hardness | 30–85 (Shore A) |

| Width | Up to 3200mm |

| Color Options | Natural, translucent, red, blue, white, or custom |

| Surface | Smooth, matte, or textured |

| Certifications | FDA, LFGB, RoHS, SVHC |

| Secondary Processing | Die-cutting, strip cutting, punching, laser cutting, and adhesive backing |

Industry Applications of Food Grade Silicone Sheets

Our silicone sheeting is used in a variety of industries where non-toxicity, durability, and heat resistance are essential for safe and reliable operations.

Food Processing & Packaging

Conveyor Systems & Equipment

Brewery & Beverage Production

Bakery and Restaurant Equipment

Best Choice for Your FDA Silicone Sheet

---Production Capacity

We operate continuous calendering and mixing lines specifically for platinum-cured silicone materials. Regular production output can reach 50,000 m² per month, ensuring stable supply for OEM orders and long-term projects.

---Engineered for Performance & Safety

Our food-grade silicone sheets are engineered to deliver both performance and safety. Designed specifically for industries that require contact with food, they are guaranteed to meet regulatory standards and ensure compliance with food safety requirements. We use platinum curing to ensure consistent quality and non-yellowing properties for a longer lifespan.

---OEM & Branding Service

We support OEM cooperation for equipment manufacturers and distributors. Products can be supplied under your brand, part code, or specification. Lot numbers and QC labels can be printed for traceability if required.

---Lead Time & Minimum Order

Standard stock items have low MOQs starting from 1–2 rolls, while custom items can be negotiated according to total square meters. Typical lead time ranges from 7–15 days based on order volume and customization levels.

---Quality Assurance

Each batch undergoes hardness, thickness, and visual checks with recorded batch data for traceability. Compliance with food-contact regulations is verified through third-party laboratory testing when required by the customer.

Customer Success Stories

Case Study 1: Bakery Equipment

One of our bakery customers reported a 50% reduction in downtime after switching to our heat-resistant silicone sheets. The new material provided better heat distribution and improved non-stick properties, leading to higher productivity.

Case Study 2: Beverage Industry

A beverage manufacturer switched to Suconvey's FDA-certified silicone sheets for their filling machines. The product’s chemical resistance and easy-to-clean surface led to a 20% increase in efficiency and helped meet industry hygiene standards.

Packaging & Shipping Information

To protect the product during global transportation and storage, we apply export-grade packaging and provide flexible shipping solutions.

Pre-Shipment Inspection

Each batch is inspected before packaging to confirm hardness, thickness, surface condition, and visual uniformity. Batch codes are recorded and compliance documentation may be provided when required for regulatory purposes.

Packaging Method

Silicone sheets in roll form are wrapped with protective film to prevent dust, moisture, and surface damage. Several rolls are placed into reinforced cartons, which are then secured on fumigation-free pallets using straps and stretch film.

Shipment Options

We regularly ship to customers in Europe, North America, and Asia through sea freight, air freight, or express courier for urgent testing needs. Both FCL and LCL shipments are available.

Documentation Support

All necessary export documents can be provided for customs clearance, including commercial invoice, packing list, bill of lading or airway bill, certificate of origin, and food-contact compliance statements or test reports when applicable.

Sample Delivery

Material samples and short test rolls can be supplied for validation and equipment trials. Samples can be sent via DHL, FedEx, UPS, TNT, or using your appointed courier account.

After-Arrival Support

If any damage or discrepancies are discovered during unloading or inspection, customers may contact us within 7 days with photos and batch information. Our team will respond promptly to assess the situation and provide a reasonable solution.

Happy Customers

Year after year, multiple industries recognize Suconvey Rubber as a leader in quality, service, and innovation. We’re proud to be one of the top rubber products manufacturers in the world.

Frequently Asked Questions

If your question is not listed, please contact us.

Our food-grade silicone sheets are certified by FDA (21 CFR 177.2600) for direct food contact, and they also meet LFGB standards for European food safety regulations. Additionally, our silicone sheets are RoHS compliant and free from SVHC (Substances of Very High Concern), ensuring they meet global safety standards.

Yes, our food-grade silicone sheets can withstand temperatures ranging from −60°C to +300°C. This makes them ideal for use in high-temperature environments such as baking, cooking, and food processing equipment, where heat resistance and stability are crucial.

Absolutely! Our FDA-approved food-grade silicone sheets are safe for direct food contact and comply with the FDA 21 CFR 177.2600 standard. They are commonly used in food handling, processing, and storage applications due to their non-toxic, inert properties.

Absolutely. We provide FDA-grade silicone sheeting that meets 21 CFR 177.2600 standards for food contact. Additionally, all our silicone materials are RoHS and REACH compliant, ensuring they are free from hazardous substances and safe for global distribution in the electronics and automotive sectors.

Yes, we offer custom silicone sheets in various thicknesses, hardness (Shore A 30–90), and sizes. Additionally, we can customize colors, surface textures, and provide adhesive backing if required. Contact our team for more information about your specific needs.

With proper care and maintenance, food-grade silicone sheets can last for several years in demanding environments. The sheets are designed to resist abrasion, tearing, and degradation under extreme temperatures, chemicals, and food processing conditions.